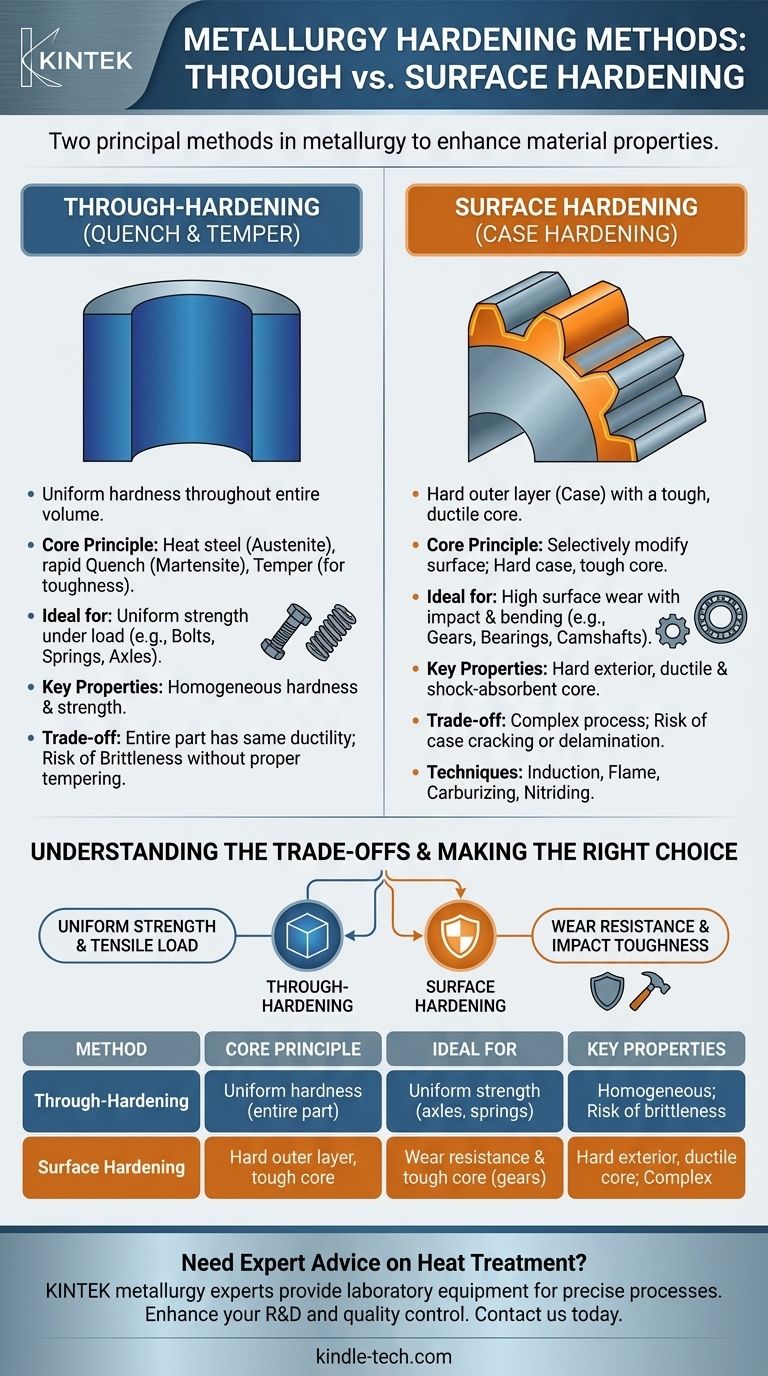

In metallurgy, the two principal methods of hardening are through-hardening and surface hardening. Through-hardening, also known as quench and tempering, imparts uniform hardness throughout the entire volume of a component. In contrast, surface hardening, or case hardening, creates an extremely hard outer layer while leaving the interior core softer and more ductile.

The choice between these two methods is a fundamental engineering decision. It requires balancing the need for a wear-resistant exterior against the need for a tough, shock-absorbent core, directly aligning the material's properties with its intended mechanical function.

Through-Hardening: Uniform Strength and Hardness

Through-hardening is a process designed to achieve consistent mechanical properties from the surface of a part all the way to its center.

The Core Principle: Quench and Temper

The process involves heating a steel with sufficient carbon content above its critical temperature, holding it there until its internal structure transforms into a phase called austenite.

The steel is then rapidly cooled, or quenched, in a medium like oil, water, or gas. This rapid cooling transforms the austenite into martensite, an extremely hard and brittle crystal structure.

Because a fully martensitic part is too brittle for most applications, it undergoes a secondary heat treatment called tempering. This involves reheating the part to a lower temperature to relieve internal stresses and increase its toughness, albeit with a slight reduction in peak hardness.

When to Use Through-Hardening

This method is ideal for components where stress is distributed throughout the cross-section. It ensures the part can resist deformation and fracture under high tensile or torsional loads.

Common applications include high-strength bolts, springs, axles, and many types of tool steel used for dies and cutters.

The Resulting Material Properties

The end result is a component with homogenous hardness and strength. This uniformity is critical for predictable performance under load, but it means the entire part shares the same level of ductility (or lack thereof).

Surface Hardening: A Tale of Two Materials

Surface hardening is a group of processes that creates a composite material in a single part: a hard, wear-resistant "case" over a tough, ductile "core."

The Core Principle: A Hard Case, A Tough Core

Unlike through-hardening, these methods selectively modify only the surface layer. This can be done by rapidly heating and quenching just the surface or by changing the surface's chemical composition.

The goal is to produce hard martensite only in the outer layer, which will resist abrasion and wear. The core, which is not affected or cools more slowly, retains its original softer, tougher, and more fatigue-resistant properties.

When to Use Surface Hardening

This approach is perfectly suited for parts that experience high surface wear while also needing to withstand impact and bending forces without fracturing.

Gears are a classic example. The tooth surfaces must be incredibly hard to resist wear, but the body of the gear needs to be tough to absorb the shock of meshing teeth without cracking. Other applications include camshafts, bearings, and crankshafts.

Common Surface Hardening Techniques

Methods like induction hardening and flame hardening use localized, rapid heating followed by quenching.

Other methods, such as carburizing and nitriding, involve heating the part in a carbon-rich or nitrogen-rich atmosphere. These elements diffuse into the surface, increasing its hardenability before the final quench.

Understanding the Trade-offs

Neither method is universally superior; the choice involves critical engineering compromises.

Through-Hardening: The Risk of Brittleness

A fully hardened, untempered part is extremely brittle and can fail catastrophically under sharp impact. The process can also induce significant internal stress and distortion, especially in complex shapes. Proper tempering is essential but requires precise control.

Surface Hardening: Complexity and Delamination

Surface hardening processes can be more complex and costly, requiring specialized equipment. There is also a physical limit to the depth of the hardened case. In cases of extreme overload, there is a risk of the hardened case cracking or delaminating from the softer core.

The Impact of Material Selection

Material choice is paramount. Through-hardening requires medium to high-carbon steels to achieve significant hardness. Conversely, many surface hardening techniques like carburizing are specifically designed for low-carbon steels, which have a tough core but cannot be effectively through-hardened.

Making the Right Choice for Your Application

Selecting the correct method hinges on the mechanical demands of the component.

- If your primary focus is uniform strength and resistance to tensile loads: Through-hardening is the superior choice, as it ensures consistent properties throughout the component.

- If your primary focus is wear resistance combined with impact toughness: Surface hardening provides the ideal combination of a hard exterior and a ductile, shock-absorbing core.

Understanding this fundamental distinction allows you to engineer components that are not just hard, but perfectly suited to their task.

Summary Table:

| Method | Core Principle | Ideal For | Key Properties |

|---|---|---|---|

| Through-Hardening | Heats and quenches entire part for uniform hardness. | Parts needing uniform strength (axles, springs, bolts). | Homogeneous hardness and strength; risk of brittleness. |

| Surface Hardening | Hardens only the outer layer, leaving a tough core. | Parts needing wear-resistant surfaces and tough cores (gears, bearings). | Hard exterior, ductile core; complex process, risk of delamination. |

Need expert advice on heat treatment for your components?

Choosing the right hardening method is critical to your component's performance, durability, and cost-effectiveness. The metallurgy experts at KINTEK are here to help.

We specialize in providing the laboratory equipment and consumables necessary for precise heat treatment processes. Whether you are developing through-hardened tools or surface-hardened transmission parts, we can support your R&D and quality control with reliable solutions.

Contact us today to discuss your project requirements and discover how KINTEK can enhance your lab's capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the purpose of radiation as a heat transfer? Achieve Non-Contact Heating in a Vacuum

- How does a pit furnace work? Prevent Distortion in Long Parts with Vertical Heat Treatment

- What is the role of high-temperature furnaces in molten chloride salt preparation? Master Purity & Dehydration

- What is the primary function of a vacuum heating furnace? Optimize High-Purity Li2O Synthesis

- What are the materials for vacuum hardening? A Guide to High-Performance Steel Selection

- What is quenching heat treatment on aluminum? Unlock Maximum Strength and Precision

- Should I use flux when brazing aluminum? The Critical Role of Flux in Achieving a Strong Bond

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project