In essence, a laboratory furnace is used for any process requiring precise, high, and sustained heat. These devices are critical for transforming materials and driving chemical reactions across a vast range of scientific and industrial fields, including materials science, engineering, and chemistry. Their core purpose is to provide a highly controlled thermal environment, often exceeding 1000°C, for extended periods.

A laboratory furnace is not just a high-powered oven; it is a precision instrument for manipulating the fundamental properties of materials. Its value lies in its ability to apply specific, uniform, and sustained thermal energy to induce desired physical or chemical changes.

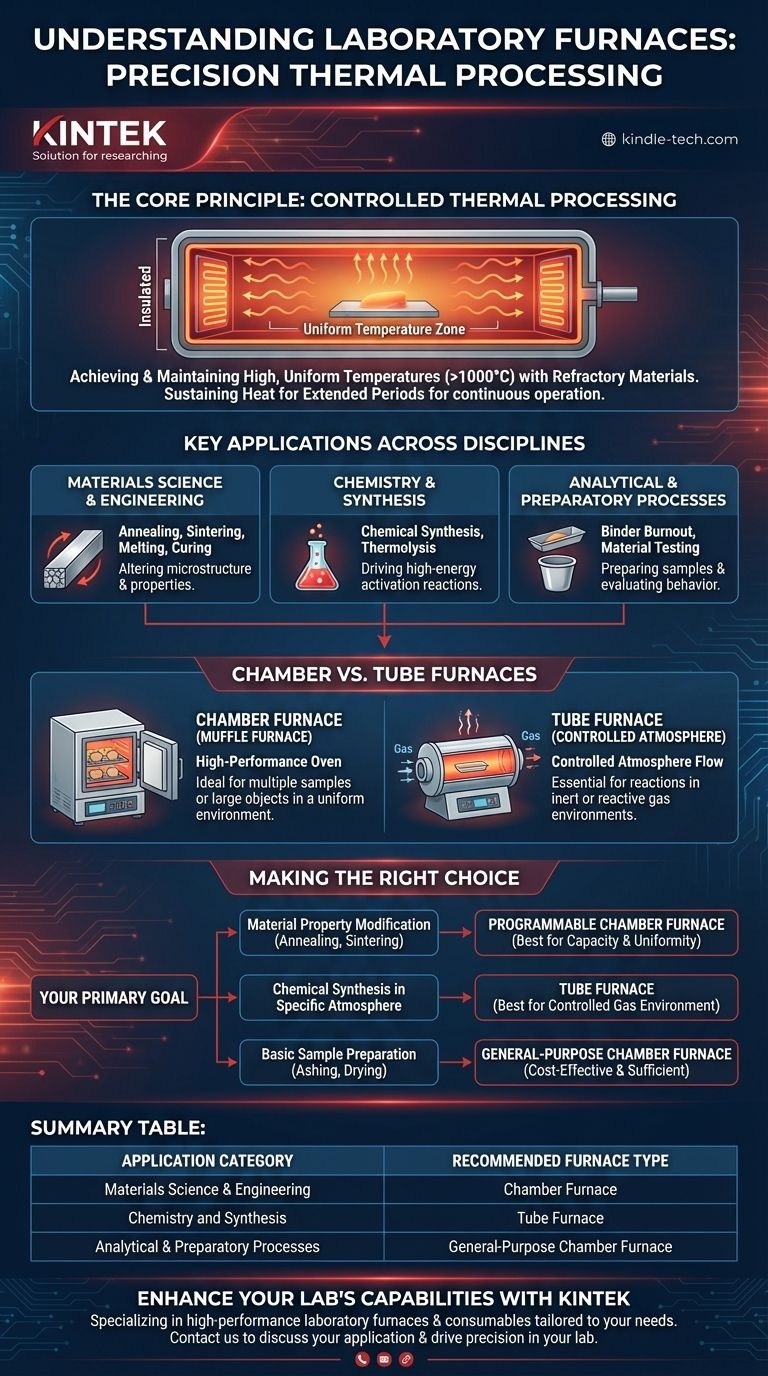

The Core Principle: Controlled Thermal Processing

The function of any laboratory furnace boils down to one goal: achieving and maintaining a specific thermal profile. This capability is what enables groundbreaking work in labs around the world.

Achieving High, Uniform Temperatures

A furnace generates and transfers heat, typically through radiation, into an insulated chamber. This method ensures the item being processed receives heat energy evenly from all sides, creating a highly uniform temperature zone.

The chamber itself is constructed from refractory materials, advanced ceramics that can withstand extreme temperatures for long durations without degrading. This robust construction is fundamental to the furnace's reliability.

Sustaining Heat for Extended Periods

Unlike simple ovens, laboratory furnaces are engineered for continuous, long-term operation. Some material processes, like crystal growth or complex ceramic curing, can require a furnace to run uninterrupted for days, weeks, or even months to complete a single cycle.

Key Applications Across Disciplines

The ability to control heat with such precision unlocks a wide array of applications. These can be broadly categorized by their primary function.

Materials Science & Engineering

This is the most common domain for laboratory furnaces. They are used to fundamentally alter the microstructure and properties of materials.

- Annealing: Heating and then slowly cooling a metal to make it less brittle and more ductile.

- Sintering: Fusing powdered materials (like ceramics or metals) into a solid, coherent mass by applying heat below the melting point.

- Melting: Creating metal alloys or glasses by heating constituent materials above their liquefaction point.

- Curing: Hardening materials like advanced ceramics or composites by holding them at a specific temperature.

Chemistry and Synthesis

In chemistry, heat is a primary catalyst for driving or enabling reactions that would not occur at room temperature.

- Chemical Synthesis: Creating new compounds or materials that require high-energy activation.

- Thermolysis: Using high heat to break down compounds into their constituent parts. A classic example is the use of a tube furnace to produce ketenes for organic synthesis.

Analytical and Preparatory Processes

Furnaces are also workhorses for preparing samples for further analysis or completing a manufacturing step.

- Binder Burnout: A crucial pre-sintering step where a furnace is used to slowly and carefully vaporize organic binding agents from a "green" ceramic or metal part.

- Material Testing: Evaluating how a material or component behaves and degrades under extreme thermal stress.

Understanding the Trade-offs: Chamber vs. Tube Furnaces

While many types of furnaces exist, the most common distinction is between chamber and tube furnaces. Choosing the right one depends entirely on the application.

Chamber Furnaces: The General Workhorse

A chamber furnace (or muffle furnace) functions like a high-performance oven. Samples are placed inside a box-like chamber. Its strength lies in processing multiple samples or larger, irregularly shaped objects within a highly uniform temperature environment.

Tube Furnaces: For Controlled Atmospheres and Flow

A tube furnace uses a cylindrical tube (often made of ceramic or quartz) as its heating chamber. This design is ideal for processes that require a tightly controlled atmosphere. Gases can be flowed through the tube, allowing for reactions in inert (e.g., argon) or reactive (e.g., hydrogen) environments, which is impossible in a standard chamber furnace open to the air.

Making the Right Choice for Your Process

Selecting the appropriate furnace requires a clear understanding of your end goal. Modern furnaces offer advanced features like temperature ramping, programmable controllers, and timers that allow for highly specific and repeatable thermal profiles.

- If your primary focus is material property modification (e.g., annealing, sintering): A programmable chamber furnace is often the best choice for its capacity and uniform heating of solid parts.

- If your primary focus is chemical synthesis or reactions in a specific atmosphere: A tube furnace is essential for its ability to control the gaseous environment around the sample.

- If your primary focus is basic sample preparation (e.g., ashing, drying at high temperatures): A simpler, general-purpose chamber furnace without advanced programming may be sufficient and more cost-effective.

Ultimately, a laboratory furnace is a tool that grants researchers and engineers precise control over one of the most fundamental agents of change: heat.

Summary Table:

| Application Category | Primary Functions | Recommended Furnace Type |

|---|---|---|

| Materials Science & Engineering | Annealing, Sintering, Melting, Curing | Chamber Furnace (Muffle Furnace) |

| Chemistry and Synthesis | Chemical Synthesis, Thermolysis | Tube Furnace |

| Analytical & Preparatory Processes | Binder Burnout, Material Testing | General-Purpose Chamber Furnace |

Ready to enhance your lab's capabilities with the right furnace?

KINTEK specializes in providing high-performance laboratory furnaces and consumables tailored to your specific research or industrial needs. Whether you require the uniform heating of a chamber furnace for material testing or the controlled atmosphere of a tube furnace for chemical synthesis, our experts are here to help you select the perfect equipment.

Contact us today to discuss your application and discover how KINTEK's solutions can drive precision and efficiency in your lab.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- Why Use a Quartz Tube Reactor for Y-Ti-O Phase Transformations? Achieve Absolute Purity and Precision Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation