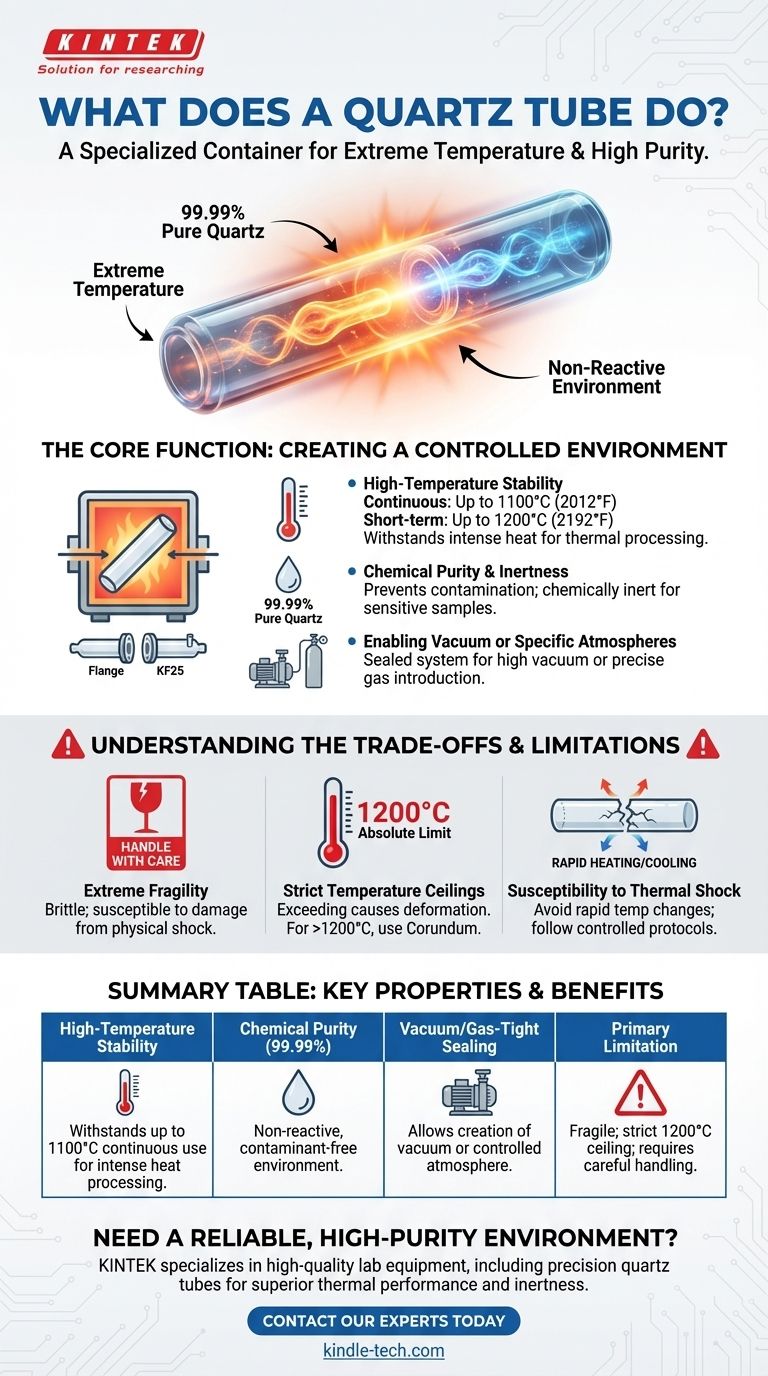

At its core, a quartz tube serves as a specialized container designed to operate under conditions of extreme temperature and high purity. It is engineered from 99.99% pure quartz, allowing it to house materials or processes that require a pristine, non-reactive, and thermally stable environment, most commonly within a tube furnace.

A quartz tube is not merely a piece of glassware; it is a critical component that creates a precisely controlled and isolated environment, enabling high-temperature chemical reactions, material synthesis, and thermal processing that would otherwise be impossible.

The Core Function: Creating a Controlled Environment

A quartz tube's primary role is to isolate a sample or process from the outside world. This isolation is achieved through a combination of material properties and system design.

High-Temperature Stability

A key function of the quartz tube is to withstand intense heat. It is reliably rated for continuous use at temperatures up to 1100°C (2012°F).

For brief periods, it can handle short-term exposure up to 1200°C (2192°F). Pushing beyond this limit risks permanent deformation and failure of the tube.

Chemical Purity and Inertness

The tube is made from 99.99% pure quartz, which is chemically inert. This extreme purity is critical because it prevents the tube itself from reacting with or contaminating the samples inside, ensuring the integrity of the experiment or process.

Enabling Vacuum or Specific Atmospheres

Quartz tubes are typically integrated into a larger assembly with flanges and valves. These fittings, often made of stainless steel, allow the tube to be sealed.

This seal enables operators to either pump out the air to create a high vacuum or to introduce specific gases, creating a precisely controlled atmosphere for the process inside. Interfaces like a KF25 port are standard for connecting to a vacuum pump system.

Understanding the Trade-offs and Limitations

While powerful, quartz is not without its challenges. Understanding its limitations is crucial for successful and safe operation.

Extreme Fragility

The primary trade-off for quartz's thermal performance and purity is its fragility. The material is brittle and highly susceptible to damage from physical shock.

It must be handled gently at all times, avoiding collisions, drops, or even strong vibrations, which can cause microscopic fractures that lead to failure under heat and pressure.

Strict Temperature Ceilings

The 1200°C short-term temperature limit is an absolute ceiling. Exceeding it will cause the quartz to soften and deform, compromising the structural integrity of the entire system.

For applications requiring temperatures above this limit, an alternative material such as a corundum tube must be used.

Susceptibility to Thermal Shock

Rapid changes in temperature can create internal stresses that will crack the tube. Both heating and cooling rates must be carefully controlled to prevent this thermal shock. Never place a hot tube on a cold surface or introduce a cold item into a hot tube.

Making the Right Choice for Your Application

Proper use of a quartz tube hinges on respecting its properties. Your operational goal will dictate how you approach its use.

- If your primary focus is high-purity processing below 1100°C: A quartz tube is the ideal and standard choice for creating a clean, controlled, and thermally stable environment.

- If your primary focus is working with temperatures above 1200°C: You must use an alternative material, as a quartz tube is not suitable and will fail.

- If your primary focus is operational safety and longevity: Prioritize careful handling and strict adherence to gradual heating and cooling protocols to avoid both physical breakage and thermal shock.

Understanding these capabilities and limitations is the key to leveraging a quartz tube for reliable and repeatable results.

Summary Table:

| Key Property | Function & Benefit |

|---|---|

| High-Temperature Stability | Withstands continuous use up to 1100°C, enabling intense heat processing. |

| Chemical Purity (99.99%) | Provides a non-reactive, contaminant-free environment for sensitive materials. |

| Vacuum/Gas-Tight Sealing | Allows creation of a vacuum or controlled atmosphere for precise reactions. |

| Primary Limitation | Fragile; requires careful handling and has a strict 1200°C temperature ceiling. |

Need a reliable, high-purity environment for your lab processes?

A quartz tube is essential for high-temperature applications where contamination cannot be tolerated. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including precision quartz tubes designed for superior thermal performance and chemical inertness.

Let us help you achieve precise and repeatable results. Contact our experts today to find the perfect quartz tube solution for your specific laboratory needs.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What size is a quartz tube? Custom Dimensions for Your Lab's Furnace & Process Needs

- Why select tungsten carbide grinding balls for chromium & silicon? Maximize Milling Power and Purity

- What is the difference between a single-stage and a two-stage rotary vane pump? Choosing the Right Vacuum Depth

- What are the advantages of using zirconia milling jars for sulfide electrolytes? Enhance Purity and Conductivity

- What is the purpose of fluxing? The Essential Guide to Strong, Reliable Solder Joints

- How do precision ovens or drying equipment affect film quality? Ensure defect-free GPTMS-modified cellulose sensors.

- Why is a programmable temperature controller necessary during the annealing process of manganese coatings?

- How does a magnetic stirrer hotplate contribute to Al-MOF carbon activation? Maximize Porosity and Adsorption Performance