At its core, brazing equipment is designed to join metals by melting a specialized filler material into a joint. This equipment precisely heats two or more parent metals to a temperature high enough to melt the filler metal, but not the metals being joined. The molten filler is then drawn into the gap between the parts by capillary action, creating a strong, permanent bond as it cools and solidifies.

The crucial function of modern brazing equipment, particularly vacuum furnaces, extends beyond simple heating. It creates a highly controlled environment that chemically cleans the metal surfaces, allowing the filler metal to form a perfect, continuous metallurgical bond that is often as strong as the parent materials themselves.

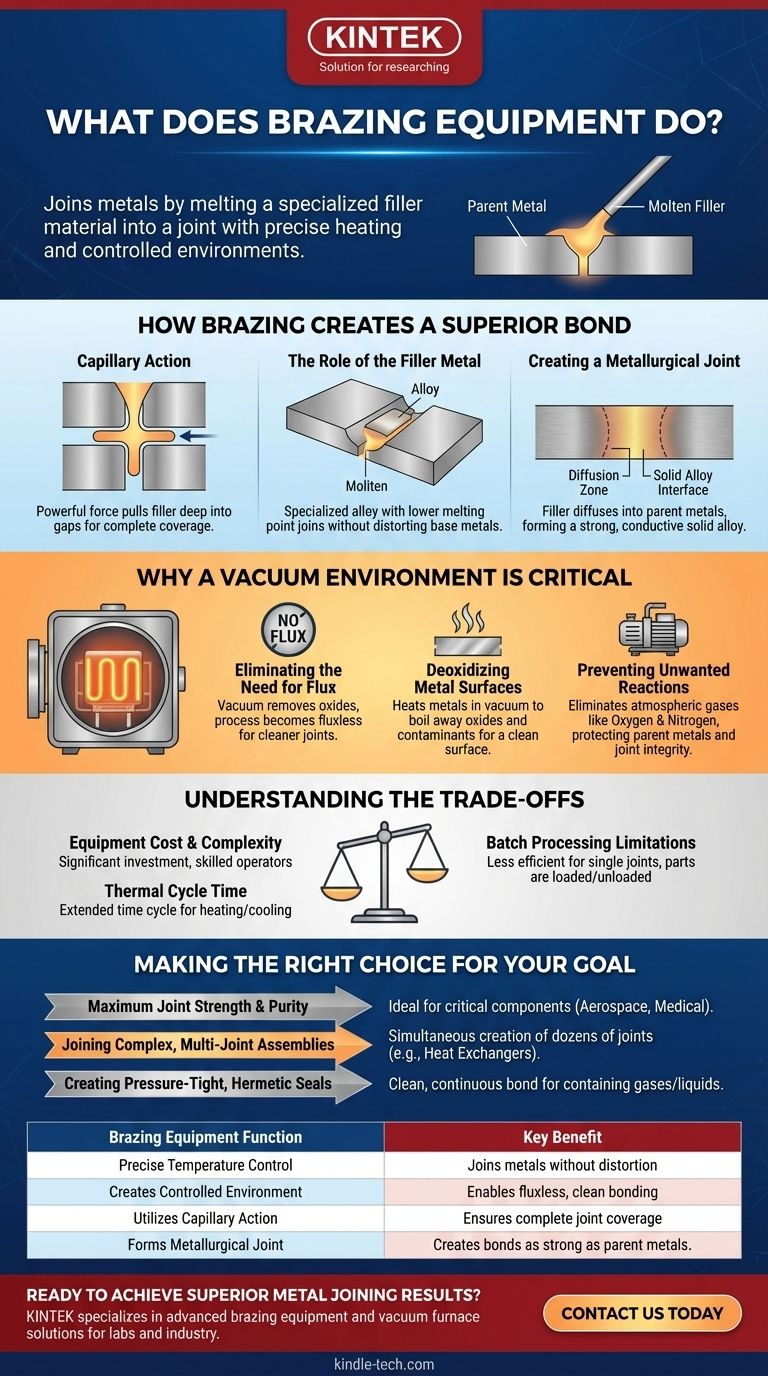

How Brazing Creates a Superior Bond

The effectiveness of brazing lies in its ability to create a clean, complete, and diffused joint between components without melting them. This is achieved through a combination of precise temperature control and material science.

The Principle of Capillary Action

When the filler metal becomes liquid, the close fit between the parts being joined creates a powerful force known as capillary action. This force pulls the molten filler deep into the tiny gaps of the joint, ensuring complete coverage and a void-free bond.

The Role of the Filler Metal

The filler metal is a specialized alloy with a melting point lower than the base metals. This is the key principle that allows brazing to join materials without distorting, stressing, or melting them, preserving their original properties.

Creating a Metallurgical Joint

As the filler metal solidifies, it doesn't just act as a glue. It diffuses slightly into the surface of the parent metals, forming a new, solid alloy at the interface. This creates a true metallurgical joint that is exceptionally strong and conductive.

Why a Vacuum Environment is Critical

Many advanced brazing applications are performed in a vacuum furnace. This controlled atmosphere is not incidental; it is fundamental to achieving the highest quality joints, especially with reactive or sensitive materials.

Eliminating the Need for Flux

In open-air brazing, a chemical agent called flux is required to clean oxides from the metal surfaces. A vacuum environment makes the process fluxless. The vacuum itself removes oxides and prevents new ones from forming, resulting in a cleaner joint with no risk of trapped corrosive flux.

Deoxidizing Metal Surfaces

Heating metals in a vacuum effectively boils away surface oxides and other contaminants like oils. This process, known as deoxidizing, presents a perfectly clean, raw metal surface for the filler to bond with, dramatically increasing joint integrity.

Preventing Unwanted Reactions

Atmospheric gases like oxygen and nitrogen can react with hot metals to form brittle, weakening compounds. A vacuum eliminates these gases, protecting the integrity of both the parent metals and the final joint. This is especially critical for materials like titanium and stainless steel.

Understanding the Trade-offs

While vacuum brazing offers superior results, it's essential to understand its practical limitations compared to other joining methods.

Equipment Cost and Complexity

A vacuum brazing furnace is a significant investment. It is a piece of precision industrial equipment that requires skilled operators and controlled processes, making it more expensive than a simple welding torch or soldering iron.

Batch Processing Limitations

Brazing in a furnace is a batch process. Parts are loaded, the furnace runs a specific heating and cooling cycle, and then the parts are unloaded. This can be less efficient for single, simple joints compared to the continuous nature of welding.

Thermal Cycle Time

The entire process of heating a large furnace, holding the temperature, and then cooling it down under vacuum can take several hours. This extended time cycle must be factored into production planning.

Making the Right Choice for Your Goal

Selecting vacuum brazing depends entirely on the requirements for the final component.

- If your primary focus is maximum joint strength and purity: Vacuum brazing is the superior choice for critical components where failure could be catastrophic, such as in aerospace or medical applications.

- If your primary focus is joining complex, multi-joint assemblies: The uniform heating of a furnace ensures that dozens or even hundreds of joints on a complex part, like a heat exchanger, are created simultaneously and reliably.

- If your primary focus is creating pressure-tight, hermetic seals: The clean, continuous bond created by vacuum brazing is ideal for components that must contain gases or liquids under pressure.

Ultimately, modern brazing equipment empowers engineers to create complex and highly reliable assemblies that would be impossible to produce with other methods.

Summary Table:

| Brazing Equipment Function | Key Benefit |

|---|---|

| Precise Temperature Control | Joins metals without distortion |

| Creates Controlled Environment | Enables fluxless, clean bonding |

| Utilizes Capillary Action | Ensures complete joint coverage |

| Forms Metallurgical Joint | Creates bonds as strong as parent metals |

Ready to achieve superior metal joining results? KINTEK specializes in advanced brazing equipment and vacuum furnace solutions for laboratories and industrial applications. Our expertise ensures you get the perfect bond strength and purity for critical components in aerospace, medical, and other high-reliability sectors.

Contact us today to discuss how our brazing solutions can enhance your manufacturing processes and deliver reliable, high-performance joints for your most demanding applications.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is the process of vacuum brazing? Achieve High-Purity, Strong Metal Joining

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining