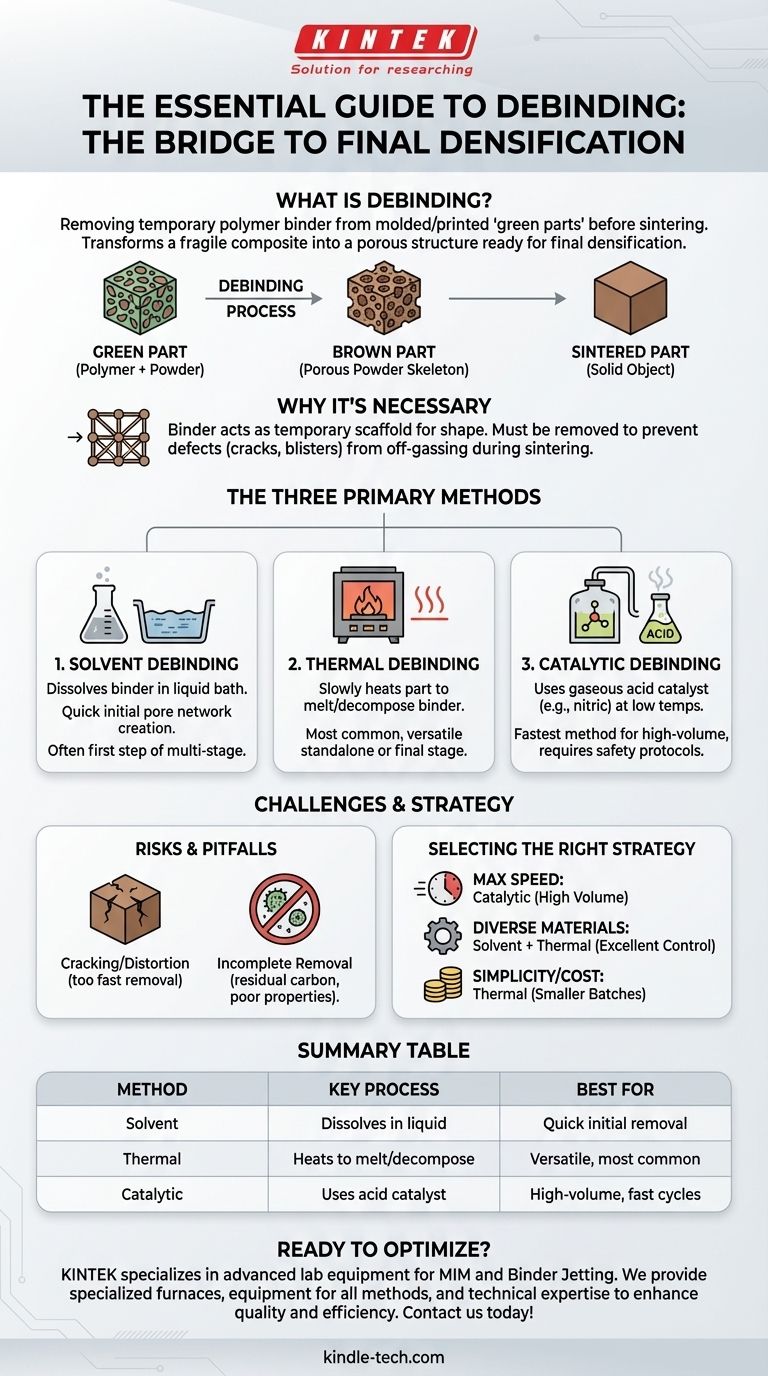

In advanced manufacturing, debinding is the essential process of removing a temporary polymer “binder” from a molded or printed component, known as a "green part." This critical intermediate step takes place after initial forming (like Metal Injection Molding or Binder Jetting) and before the final heat treatment (sintering), which fuses the material particles into a dense, solid object.

Debinding transforms a fragile, polymer-and-powder composite into a porous, pure-powder structure ready for final densification. The method and precision of binder removal are paramount, as they directly determine the structural integrity and quality of the final part.

Why Debinding is a Necessary Step

Before a metal or ceramic powder can be sintered into its final form, the binder that gave it its initial shape must be completely and carefully eliminated.

The "Green Part": A Temporary Composite

A "green part" is the initial component produced by a process like Metal Injection Molding (MIM) or binder jet 3D printing. It is not made of pure metal or ceramic but is a composite mixture of the final powder material and a significant amount of a polymer binder.

The Binder's Role as a "Scaffold"

The binder acts as a temporary scaffolding. During molding or printing, it liquefies to carry the powder particles and fills the mold cavity, then solidifies to give the green part its precise shape and enough strength for handling.

Preparing for Final Sintering

This binder must be removed before the part enters the high-temperature sintering furnace. If it were left in, the binder would rapidly burn off during sintering, releasing gases that would create cracks, blisters, and catastrophic defects in the final component. Debinding removes this scaffold in a controlled manner.

The Three Primary Debinding Methods

The choice of debinding method depends on the binder system, part geometry, material, and production requirements. Most modern processes use a combination of methods.

1. Solvent Debinding

In solvent debinding, the green part is immersed in a liquid bath. The liquid acts as a solvent, dissolving a significant portion of the binder system.

This process is often the first step in a multi-stage approach. It works quickly to open up a network of pores within the part, allowing the remaining binder to be removed more easily in a subsequent thermal step.

2. Thermal Debinding

Thermal debinding is the most common method, either as a standalone process or as the final stage after solvent debinding. The part is slowly heated in a controlled-atmosphere furnace.

The heat first melts the remaining binder, allowing it to wick to the surface, and then carefully increases to a temperature where the binder thermally decomposes and evaporates. The rate of heating is critical to prevent defects.

3. Catalytic Debinding

This is the fastest method. The green parts are placed in an oven with a gaseous acid, typically nitric acid, which acts as a catalyst. At relatively low temperatures (around 120°C), the catalyst breaks down the primary binder (often polyacetal) into formaldehyde, which is then exhausted from the furnace.

While extremely fast, this method requires specialized equipment and strict safety protocols due to the use of a hazardous acid.

Understanding the "Brown Part"

The component that exists after the debinding process is complete is called a "brown part."

A Fragile, Porous Skeleton

The brown part is a porous structure composed almost entirely of the metal or ceramic powder. The binder is gone, and the powder particles are held together only by weak friction and inter-particle forces.

Because of its porosity, the brown part is extremely fragile and chalk-like. It must be handled with extreme care to prevent breakage before it moves to the sintering furnace.

The Ideal State for Sintering

The network of pores left by the departed binder is essential for successful sintering. It allows for uniform heat transfer and provides the space needed for the part to shrink and densify into a solid, high-performance component.

Understanding the Trade-offs and Pitfalls

Debinding is a delicate balance. Errors in this stage are a primary cause of part failure.

Risk of Cracking and Distortion

If the binder is removed too quickly—for example, by heating the part too fast—the gases from the decomposing polymer can build up internal pressure. This pressure will crack the part or cause it to slump and distort.

Incomplete Binder Removal

Failing to remove all of the binder is equally problematic. Residual carbon from the binder can interfere with the metallurgy during sintering, leading to brittleness or poor mechanical properties in the final part.

Speed vs. Cost and Complexity

Catalytic debinding offers unparalleled speed for high-volume production but comes with high capital costs and significant safety/environmental considerations. Thermal debinding is slower but more versatile and generally less expensive to implement.

Selecting the Right Debinding Strategy

Your choice should align directly with your production goals, material choice, and part complexity.

- If your primary focus is maximum production speed for large volumes: Catalytic debinding is the industry standard for its rapid cycle times, despite higher initial investment.

- If your primary focus is processing diverse materials or complex geometries: A two-step solvent and thermal process offers excellent control and versatility for a wide range of applications.

- If your primary focus is simplicity and lower equipment cost for smaller batches: A straight thermal debinding process is the most straightforward, though it requires the longest cycle times.

Mastering the debinding process is the non-negotiable bridge between a raw powder and a precision-engineered final component.

Summary Table:

| Debinding Method | Key Process | Best For |

|---|---|---|

| Solvent Debinding | Dissolves binder in liquid bath | Quick initial removal, creating porous structure |

| Thermal Debinding | Heats part to melt/decompose binder | Versatile applications, most common method |

| Catalytic Debinding | Uses gaseous acid catalyst at low temps | High-volume production with fast cycle times |

Ready to Optimize Your Debinding Process?

KINTEK specializes in advanced lab equipment and consumables for manufacturing applications like Metal Injection Molding (MIM) and binder jet 3D printing. Our solutions help you achieve precise debinding control, prevent part defects, and ensure successful sintering outcomes.

We provide:

- Specialized debinding furnaces with precise temperature control

- Equipment for solvent, thermal, and catalytic debinding processes

- Technical expertise to match your production goals and material requirements

Contact us today to discuss how our debinding solutions can enhance your manufacturing quality and efficiency. Get in touch via our contact form for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Why must green bodies produced via binder jetting undergo treatment in a vacuum sintering furnace?