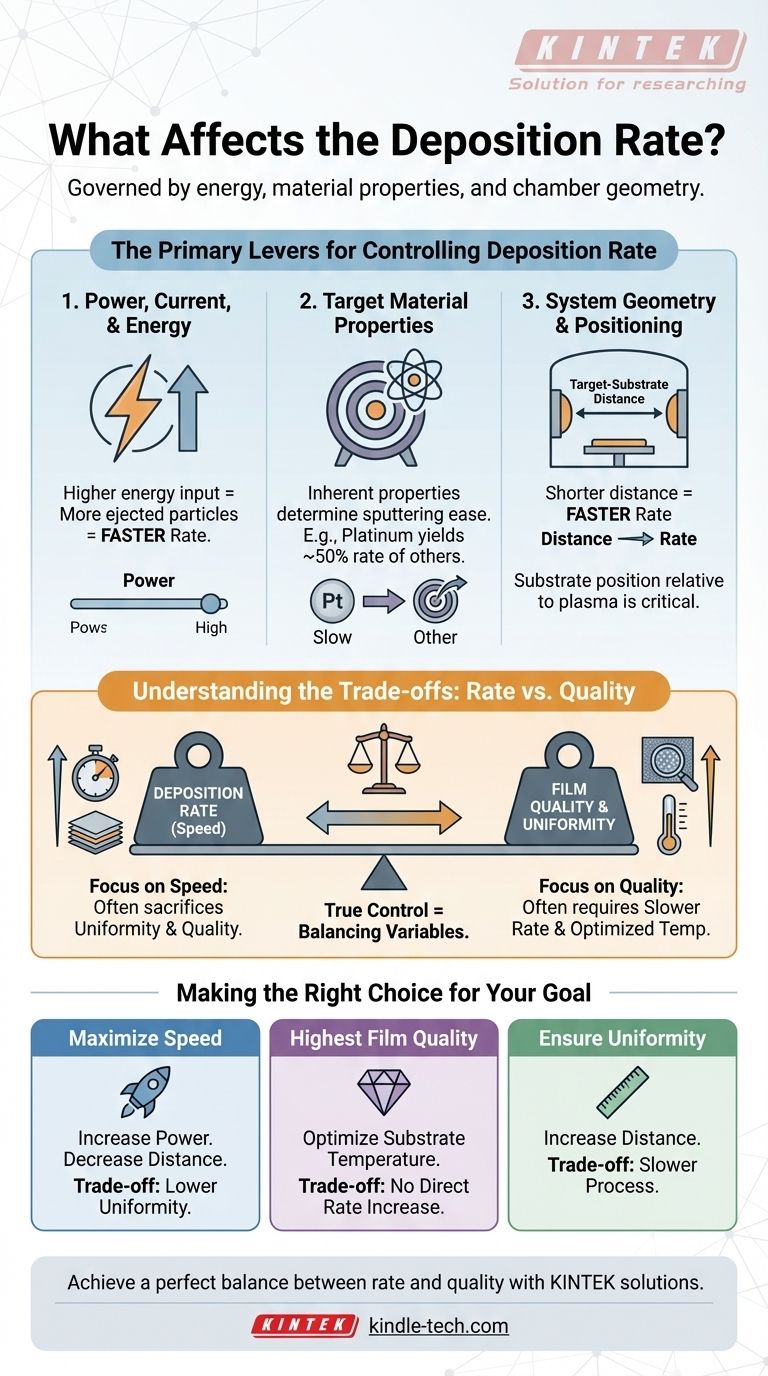

At its core, the deposition rate in processes like sputtering is primarily governed by the energy applied to the system, the physical properties of the source material, and the physical geometry of the deposition chamber. Key factors you can control include the applied power, the choice of target material, and the distance between the target and the substrate.

While it's tempting to focus solely on increasing deposition speed, the central challenge is that the factors that boost rate often negatively impact other critical outcomes, such as film uniformity and quality. True process control involves balancing these competing variables.

The Primary Levers for Controlling Deposition Rate

To effectively manage your deposition process, you must understand the distinct impact of each primary variable. These are the main "levers" you can pull to adjust the outcome.

Power, Current, and Energy

The amount of energy directed at the source material is the most direct way to influence the deposition rate. This is often controlled via power, current, or beam energy.

Increasing the energy input causes more particles to be ejected from the target material in a given amount of time, which translates directly to a faster deposition rate on your substrate.

Target Material Properties

The material you are depositing plays a fundamental role in the achievable rate. Different materials have different physical properties, such as atomic mass and binding energy, which determine how easily they are sputtered.

For example, a platinum target will yield approximately half the deposition rate of many other common materials under the same conditions. This is an inherent property of the material itself.

System Geometry and Positioning

The physical setup of your deposition chamber has a profound impact on rate and uniformity. The most critical geometric factor is the target-substrate distance.

As a general rule, decreasing the distance between the source target and the substrate will increase the deposition rate, as more of the sputtered flux is intercepted. Conversely, increasing this distance will lower the rate.

The position of the substrate relative to the plasma or erosion zone is also critical. The rate often varies within the chamber, sometimes reaching a maximum at a specific distance from an electrode or the center of the erosion zone.

Understanding the Trade-offs: Rate vs. Quality

Optimizing a deposition process is rarely about maximizing a single metric. Adjusting for a faster rate almost always involves a trade-off with film quality or consistency.

The Impact of Substrate Temperature

Substrate temperature is a perfect example of this principle. It has very little direct impact on the deposition rate.

However, temperature has a significant effect on film quality. Higher substrate temperatures provide more energy to the deposited atoms, allowing them to arrange into a denser, higher-quality film structure.

The Role of Target-Substrate Distance

While decreasing the target-substrate distance increases the rate, it often comes at the cost of thickness uniformity.

A greater distance allows the sputtered material to disperse more evenly before reaching the substrate, resulting in a more uniform coating across the entire surface, albeit at a slower rate.

The Effect of the Erosion Zone

The size of the erosion zone on the target also influences this balance. While it is a primary driver of the overall deposition rate, its size and shape directly affect the distribution of the deposited material.

A smaller, more focused erosion zone can lead to poor uniformity, even if it produces a high localized deposition rate.

Making the Right Choice for Your Goal

Your optimal settings depend entirely on what you are trying to achieve. Balance these factors based on your primary objective.

- If your primary focus is maximizing speed: Increase the power and decrease the target-substrate distance, but be prepared to sacrifice some film uniformity.

- If your primary focus is achieving the highest film quality: Prioritize optimizing the substrate temperature, even if it does not increase your deposition rate.

- If your primary focus is ensuring coating uniformity: Increase the target-substrate distance, accepting that this will slow down the overall process.

Ultimately, mastering your deposition process is about understanding and deliberately balancing these interconnected variables to achieve your desired result.

Summary Table:

| Factor | Primary Effect on Rate | Key Trade-off |

|---|---|---|

| Power / Energy | Directly increases rate | Can increase stress or damage film |

| Target Material | Inherent property (e.g., Pt is slow) | Limited choice based on application |

| Target-Substrate Distance | Shorter distance = faster rate | Reduced film uniformity |

| Substrate Temperature | Minimal direct effect | Crucial for final film quality |

Struggling to balance deposition speed with film quality in your lab? KINTEK specializes in lab equipment and consumables for precise thin-film deposition. Our experts can help you select the right sputtering targets and configure your system for optimal results. Contact us today to discuss your specific application and achieve a perfect balance between rate and quality!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is epitaxy growth of graphene? A Guide to High-Quality, Large-Area Production

- What is a primary challenge in producing usable graphene sheets after CVD? Overcoming the Transfer Bottleneck

- What critical environmental conditions does a high-temperature furnace provide for CVD aluminization? Master 1050°C Precision

- What is the material deposition method? A Guide to Coating and Thin-Film Technologies

- What is the sputtering cathode method? A Guide to Thin Film Deposition Technology

- What does sputtered mean in a sentence? A Guide to Using This Evocative Verb

- What gases are used in chemical vapor deposition? Choosing the Right Precursors for Your Thin Film

- What are external chemical vapor deposition processes? Understanding CVD Process Design and Control