In short, X-ray Fluorescence (XRF) cannot detect the very lightest elements on the periodic table. This includes hydrogen (H), helium (He), lithium (Li), beryllium (Be), boron (B), carbon (C), nitrogen (N), oxygen (O), and fluorine (F). This is not an arbitrary limitation of the technology but a direct consequence of the fundamental physics governing these low-atomic-number elements.

The core issue is that light elements produce very low-energy "soft" X-rays that are easily absorbed by the air, the sample itself, or even the instrument's detector window. In essence, the signal is generated but is too weak to escape the sample and be measured effectively.

The Fundamental Reason: Low-Energy Signals

To understand why these elements are invisible to XRF, we first need to grasp how the technique works.

The Physics of Fluorescence

XRF operates by bombarding a sample with high-energy primary X-rays. This energy knocks an electron out of an inner atomic shell of an atom in the sample.

To regain stability, an electron from a higher-energy outer shell immediately drops down to fill the vacancy. This drop releases a specific amount of energy in the form of a secondary (or fluorescent) X-ray.

The energy of this fluorescent X-ray is the "fingerprint" of the element. The detector measures these energies to identify which elements are present.

Why Light Elements Are Different

Light elements have a low atomic number (Z), meaning they have very few protons in their nucleus and, consequently, few electrons orbiting it.

The energy difference between their electron shells is very small. Therefore, when the fluorescence process occurs, the secondary X-ray they emit has extremely low energy.

The Problem of Signal Absorption

These low-energy, or "soft," X-rays are the root of the detection problem. They lack the power to travel far.

The fluorescent signal from a light element is almost immediately absorbed by the surrounding atoms in the sample (matrix absorption), the air between the sample and the detector, and the protective window of the detector itself. The signal is lost before it can ever be counted.

Competing Processes and Detection Limits

Beyond the primary issue of signal absorption, other factors contribute to the challenge.

The Auger Effect

For very light elements, another physical process called the Auger Effect becomes more probable than X-ray fluorescence.

Instead of the atom emitting a fluorescent X-ray, the energy from the electron transition is used to eject a different electron from the atom. This process competes directly with fluorescence, effectively "stealing" the signal that an XRF detector is designed to measure.

Below the Limit of Detection (LOD)

It's important to distinguish between an element being fundamentally undetectable and simply being present at a concentration too low to measure.

Even an element that XRF can normally detect, like nickel (Ni), will not be found if it exists below the instrument's specific limit of detection for that sample type. This is a practical limitation, not a fundamental one.

Understanding the Trade-offs: Handheld vs. Laboratory XRF

Not all XRF instruments are created equal, and their capabilities at the low end of the periodic table differ significantly.

Handheld (EDXRF) Limitations

Portable, handheld XRF analyzers are typically Energy Dispersive (EDXRF). They are designed for speed and convenience and operate in the open air.

Because of air absorption and the need for a durable detector window, these instruments generally cannot detect elements lighter than magnesium (Mg). Some specialized models may detect down to sodium (Na), but that is often their absolute limit.

Laboratory (WDXRF) Capabilities

High-end laboratory instruments, particularly Wavelength Dispersive (WDXRF) systems, can push these boundaries.

By operating under a vacuum to remove air and using ultra-thin detector windows and specialized crystals, these systems can often detect elements down to boron (B) or sometimes carbon (C) under ideal conditions. However, they still cannot detect H, He, or Li due to the insurmountable physics challenges.

Making the Right Choice for Your Goal

Understanding this limitation is critical for selecting the correct analytical method for your objective.

- If your primary focus is identifying common alloys, minerals, or heavy metals: XRF is an excellent, fast, and non-destructive choice.

- If your primary focus is quantifying light elements like carbon in steel or oxygen in ceramics: You must use an alternative technique like Combustion Analysis or Laser-Induced Breakdown Spectroscopy (LIBS).

- If your primary focus is a complete elemental survey of an unknown material: A multi-technique approach is required; XRF can provide data on the heavier elements, but a complementary method will be needed for the light ones.

Knowing a tool's limitations is the first step toward using it effectively and ensuring your results are accurate and complete.

Summary Table:

| Element | Atomic Number | Detectable by Standard XRF? | Reason |

|---|---|---|---|

| Hydrogen (H) | 1 | No | Signal absorbed by air/sample |

| Helium (He) | 2 | No | Signal absorbed by air/sample |

| Lithium (Li) | 3 | No | Signal absorbed by air/sample |

| Beryllium (Be) | 4 | No | Signal absorbed by air/sample |

| Boron (B) | 5 | Limited (WDXRF only) | Low-energy X-rays |

| Carbon (C) | 6 | Limited (WDXRF only) | Low-energy X-rays |

| Nitrogen (N) | 7 | No | Signal absorbed by air/sample |

| Oxygen (O) | 8 | No | Signal absorbed by air/sample |

| Fluorine (F) | 9 | No | Signal absorbed by air/sample |

Need the Right Elemental Analysis Solution for Your Lab?

Understanding XRF limitations is crucial for accurate material analysis. KINTEK specializes in lab equipment and consumables, offering expert guidance to help you select the perfect analytical instrumentation for your specific needs.

Whether you require XRF for heavy element analysis or complementary techniques like LIBS for light elements, our team provides:

- Expert technical consultation to match your application with the right technology

- Comprehensive product range including XRF systems, sample preparation equipment, and consumables

- Ongoing support and training to maximize your analytical capabilities

Don't let analytical limitations compromise your results. Contact our experts today to discuss your laboratory requirements and discover how KINTEK can enhance your elemental analysis workflow.

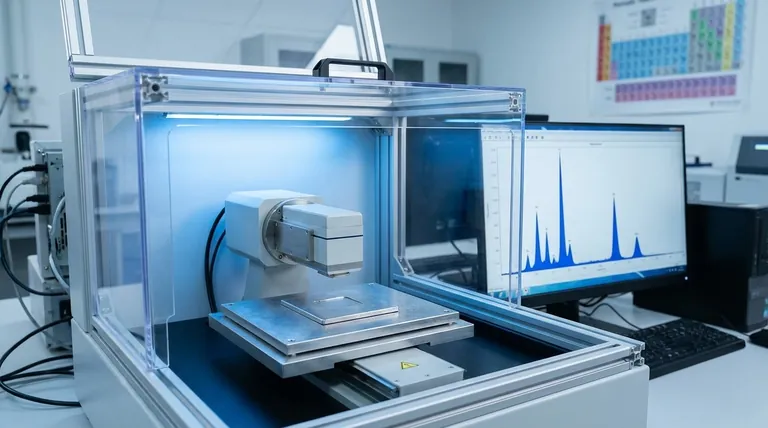

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

People Also Ask

- How do high-precision high-pressure injection pumps contribute to flow-through reactor systems? Expert Insights

- What is the advantages of using biomass? Harness Renewable, Carbon-Neutral Energy

- What is DFT coating thickness? Ensure Quality and Performance with Precise Measurement

- What are the advantages of using deionized water in HHIP? Superior Density and Microstructural Integrity

- What are the hazards of additive manufacturing? Mitigate Chemical, Physical, and Mechanical Risks

- What is gold coating SEM for? Prevent Charging & Get Clearer SEM Images

- What is the correct shutdown and disassembly procedure after an experiment? Ensure Safety and Protect Your Equipment

- What are the various biomass conversion technologies presently used? A Guide to Thermochemical & Biochemical Methods