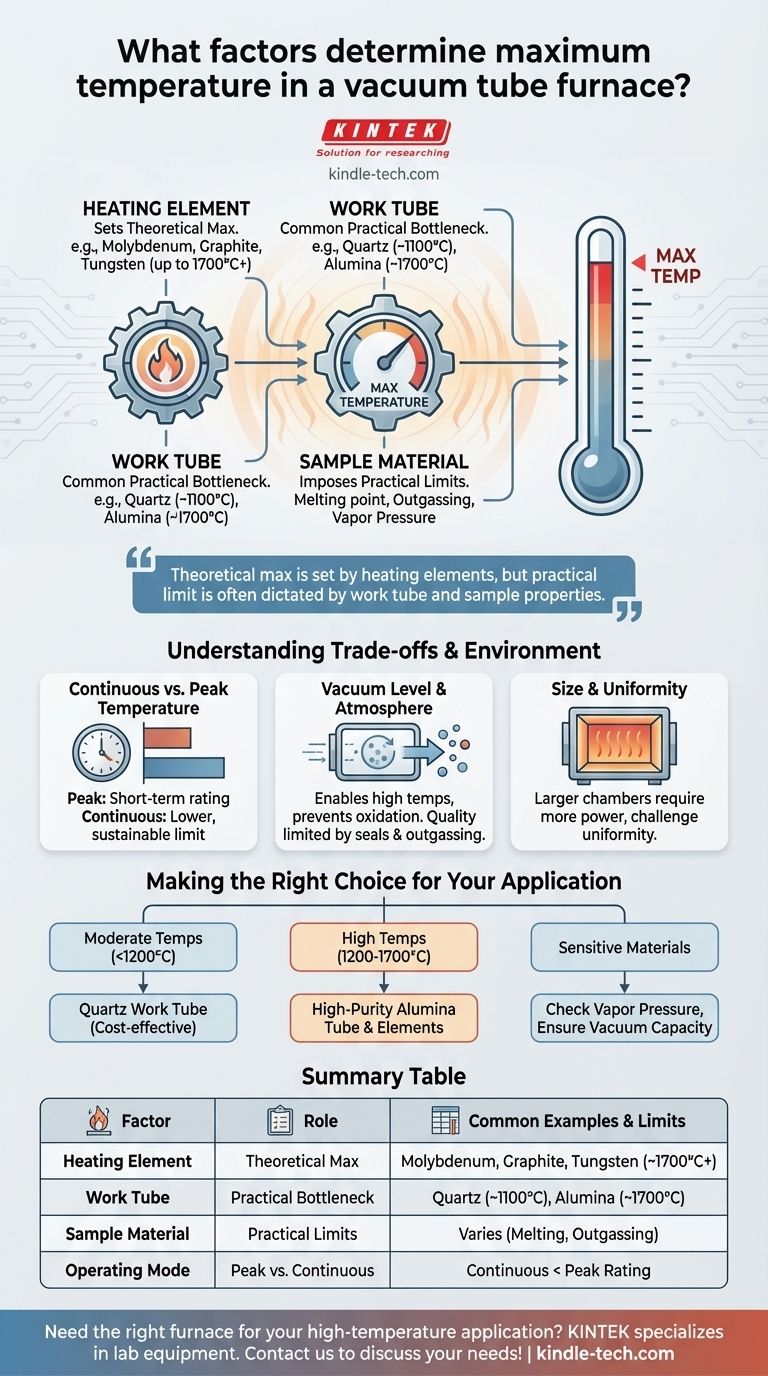

The maximum temperature of a vacuum tube furnace is not determined by a single component, but by the interplay of several critical factors. The most significant limitations are the material of the furnace's internal work tube and the design of the heating elements themselves.

The theoretical maximum temperature is set by the furnace's heating elements, but the practical, safe operating temperature is almost always dictated by the physical limits of the work tube and the properties of the material you are heating inside it.

The Primary Limiting Factors

To understand the true temperature capability of a furnace, you must look at it as an integrated system. The weakest link in the high-temperature chain defines the system's operational ceiling.

The Heating Element Material

The core of the furnace is its heating element, and its composition is the first fundamental limit. Different materials can sustain drastically different temperatures before degrading or failing.

Common heating elements include molybdenum, graphite, or tungsten, each with its own upper temperature boundary. This rating represents the absolute maximum temperature the furnace could theoretically generate.

The Work Tube Material

This is the most common practical bottleneck. The work tube contains your sample and the vacuum environment, and it must withstand extreme heat without cracking, melting, or compromising the vacuum.

Materials like quartz are common but typically limited to around 1100-1200°C. For higher temperatures, you must use more robust ceramics like alumina (up to ~1700°C) or mullite, each with a specific, non-negotiable temperature limit.

The Material Under Process

The sample you are heating is an active part of the system. Its properties can impose a practical temperature limit well below the furnace's maximum capability.

Materials have different melting points and vapor pressures. As temperature increases, a sample may melt or begin to outgas significantly, which can contaminate the furnace or prevent the system from maintaining the required vacuum level.

Understanding the Trade-offs and System Environment

Beyond the core components, the operating conditions and physical design also impose constraints that affect the achievable temperature.

Continuous vs. Peak Temperature

Manufacturers often list two temperatures: a maximum (or peak) temperature and a continuous operating temperature. The peak is a short-term rating, while the continuous temperature is what the furnace can safely maintain for extended periods without undue stress on its components. Exceeding the continuous rating for long durations will drastically shorten the life of the heating elements and tube.

Vacuum Level and Atmosphere

The vacuum itself does not determine the maximum temperature, but it is essential for enabling it. A high vacuum removes oxygen, preventing the high-temperature oxidation and burnout of both the heating elements (like graphite) and the sample.

The quality of the vacuum can be limited by the outgassing of the sample, as mentioned, or the seals and pump system of the furnace itself.

Size and Uniformity

The size of the work tube and heating chamber can also be a factor. Larger chambers require more power to heat and can present challenges in maintaining a uniform temperature across the entire zone, which may be a practical limit for your process.

Making the Right Choice for Your Application

To select the right furnace, you must match the system's limitations to your specific processing goals.

- If your primary focus is moderate temperatures (up to 1200°C): A system with a quartz work tube is the most common and cost-effective solution.

- If your primary focus is high-temperature processing (1200°C to 1700°C): You must use a furnace equipped with a high-purity alumina work tube and appropriate heating elements.

- If your primary focus is processing sensitive materials: Your main concern should be the material's vapor pressure at your target temperature and ensuring the vacuum system can handle any potential outgassing.

Understanding how these factors constrain each other is the key to safe, repeatable, and successful high-temperature processing.

Summary Table:

| Factor | Role in Determining Max Temperature | Common Examples & Limits |

|---|---|---|

| Heating Element | Sets the theoretical maximum temperature | Molybdenum, Graphite, Tungsten (e.g., up to 1700°C+) |

| Work Tube Material | The most common practical bottleneck | Quartz (~1100°C), Alumina (~1700°C) |

| Sample Material | Imposes practical limits (melting point, outgassing) | Varies by material properties |

| Operating Mode | Differentiates peak vs. continuous use | Continuous temperature is lower than peak rating |

Need the right furnace for your high-temperature application? KINTEK specializes in lab equipment and consumables, providing vacuum tube furnaces with the correct work tube and heating element combination for your specific temperature and material requirements. Our experts can help you select a system that ensures safety, repeatability, and success. Contact us today to discuss your laboratory's needs!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the temperature rating of a quartz tube? Maximize Performance & Avoid Failure

- What is a quartz heating tube? A Guide to Fast, Precise Infrared Heating

- What material are furnace tubes? Choosing the Right Material for High-Temperature Success

- What is the role of a tube reduction furnace in tungsten oxide conversion? Master Metallic Film Production

- What material is a muffle tube? A Guide to High-Temperature Ceramic Tubes

- What is a drop tube furnace? A Specialized Reactor for Particle-Level Research

- How to clean an alumina tube furnace? Extend Tube Life and Ensure Experimental Purity

- What role does a cylindrical horizontal quartz tube furnace play in manganese coatings? Master Thermal Oxidation