In a laboratory setting, there is no single type of grinder used. Instead, labs employ a range of crushers and grinders categorized into primary, secondary, and tertiary stages to systematically reduce material size. Specific examples include robust primary jaw crushers for large samples and fine mortars for producing powders.

The choice of a lab grinder is not about a single machine but about a multi-stage process. The right equipment depends entirely on whether you are performing initial coarse crushing (primary), intermediate reduction (secondary), or fine grinding (tertiary) to achieve the desired particle size.

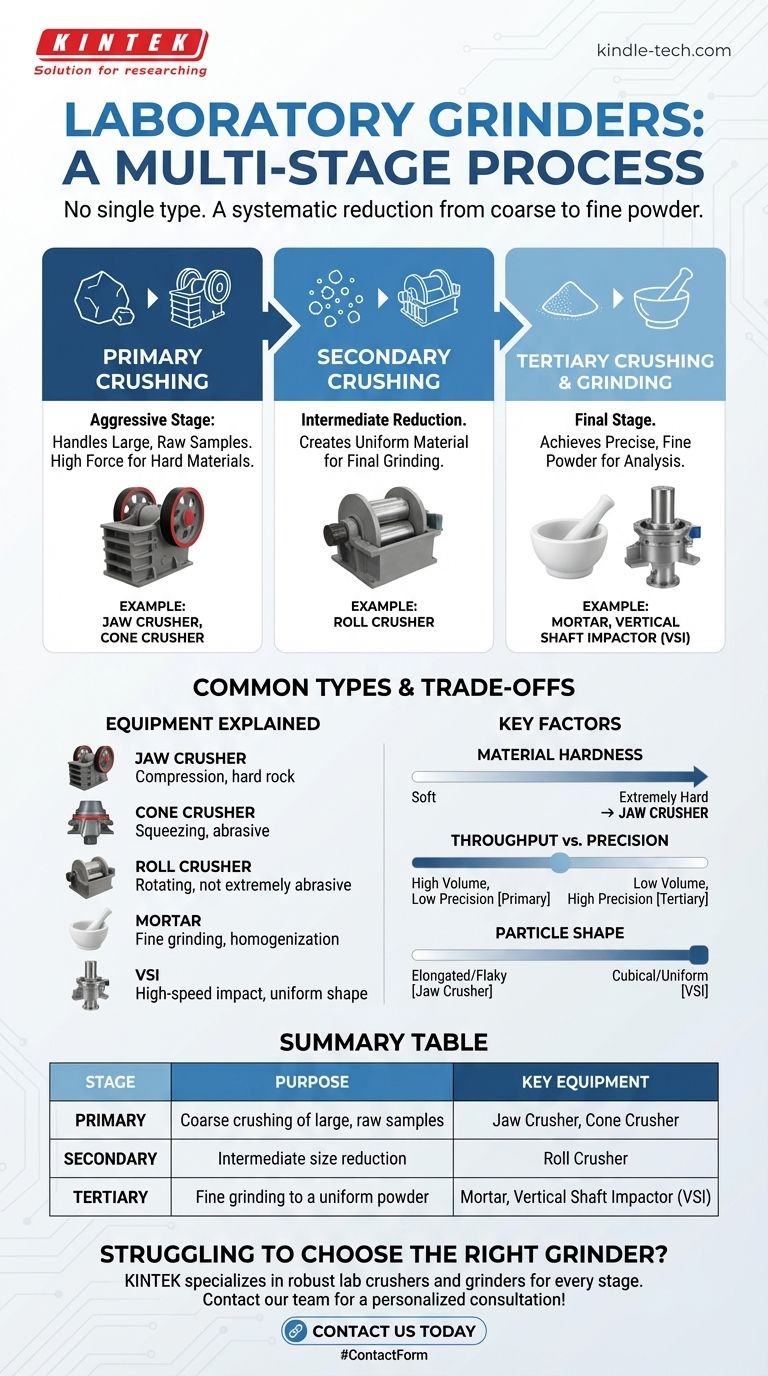

The Three Stages of Laboratory Size Reduction

Understanding the size reduction workflow is critical to selecting the correct equipment. The process is broken down into distinct stages, each requiring a different type of machine.

Primary Crushing: Handling the Raw Sample

This is the first and most aggressive stage. Its purpose is to take large, raw samples and break them down into a manageable size for the next step.

Machines used here, like jaw crushers, are designed for high force and can handle very hard materials directly from the field.

Secondary Crushing: Intermediate Size Reduction

Secondary crushers take the output from the primary stage and reduce it further. The goal is to create a more uniform material that is suitable for final grinding.

This stage bridges the gap between coarse chunks and fine particles. A roll crusher is a common example of equipment used for this intermediate step.

Tertiary Crushing & Grinding: Achieving Final Particle Size

This is the final stage, focused on producing a fine, well-graded powder with a narrow size distribution. The material is already relatively small before entering this stage.

Equipment like mortars or vertical shaft impactors are used here to achieve the precise particle size required for chemical analysis or further processing.

Common Types of Laboratory Crushers Explained

While the stages define the process, specific machines execute the work. Each is engineered for a particular type of material and reduction goal.

Jaw Crushers

These are powerful primary crushers that use two "jaws"—one fixed and one moving—to crush material through compression. They are the go-to choice for the initial breakdown of hard, brittle rock and ore.

Cone Crushers

Often used for primary or secondary crushing, a cone crusher breaks material by squeezing it between a moving cone and a stationary bowl. They are highly effective for hard and abrasive materials.

Roll Crushers

A roll crusher uses compression from two rotating cylinders to reduce material size. They are typically used in the secondary stage for materials that are not extremely abrasive.

Mortars

The classic laboratory mortar and pestle is a form of tertiary grinder. It is used for fine grinding and homogenization of small samples to create a consistent powder for analysis.

Vertical Shaft Impactors (VSI)

These machines are typically used in the tertiary stage. They work by throwing material at high speed against an impact plate, causing it to shatter along natural fracture lines, which produces a well-shaped, uniform product.

Understanding the Trade-offs

Selecting the right machine involves balancing several key factors. An incorrect choice can lead to inefficient processing or damaged equipment.

Material Hardness and Abrasiveness

The physical properties of your sample are the most critical factor. A jaw crusher is built to handle extremely hard rock, whereas a simpler crusher might fail or wear out quickly.

Throughput vs. Precision

There is a direct trade-off between volume and precision. Primary crushers can process large quantities of material quickly but offer little control over the final size. Tertiary grinders are much slower but provide exacting control over the particle distribution.

Final Particle Shape

Different machines produce different particle shapes. Impact crushers like a VSI tend to create more cubical particles, whereas compression crushers like a jaw crusher may produce more elongated, flaky particles. The required shape depends on the subsequent analysis or use.

Making the Right Choice for Your Goal

To select the correct equipment, you must first define your objective within the size-reduction workflow.

- If your primary focus is preparing a large, raw sample for initial processing: You need a primary crusher designed for coarse material, such as a jaw or cone crusher.

- If your primary focus is reducing an already crushed sample to a smaller, more manageable size: A secondary crusher, such as a roll crusher, is the appropriate choice for this intermediate step.

- If your primary focus is creating a fine, uniform powder for analysis: You must use a tertiary grinder, like a laboratory mortar or a specialized impactor.

Ultimately, selecting the correct laboratory grinder is about matching the tool to the specific stage of your size-reduction workflow.

Summary Table:

| Stage | Purpose | Key Equipment |

|---|---|---|

| Primary | Coarse crushing of large, raw samples | Jaw Crusher, Cone Crusher |

| Secondary | Intermediate size reduction | Roll Crusher |

| Tertiary | Fine grinding to a uniform powder | Mortar, Vertical Shaft Impactor (VSI) |

Struggling to choose the right grinder for your lab workflow? KINTEK specializes in lab equipment and consumables, providing robust crushers and grinders for every stage of your size-reduction process—from primary jaw crushers for hard materials to fine mortars for precise analysis. Let our experts help you select the perfect equipment to improve efficiency and achieve your target particle size. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Test Sieves and Sieving Machines

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the laboratory apparatus used for grinding? Find the Perfect Mill for Your Sample

- Why is grinding important in laboratory? Ensure Sample Homogeneity for Accurate Results

- What is a mortar and pestle used for in a lab? A Guide to Precision Grinding and Mixing

- What is a grinder used in labs? Essential for Homogeneous Sample Preparation & Analysis

- How are rock samples prepared for geochemical analysis? Ensure Accurate Results with Proper Lab Protocols