Before any experiment, a platinum wire or rod electrode requires a multi-point inspection covering its physical condition, surface cleanliness, and the integrity of its support system. You must visually check the platinum for any damage, deformation, or contamination, followed by a chemical cleaning procedure, typically with a dilute acid wash and a distilled water rinse, to remove surface oxides and impurities that can compromise your results.

A pristine electrode in a faulty setup is as unreliable as a contaminated one. Therefore, a proper pre-use inspection is not just about the electrode itself, but a holistic assessment of its surface chemistry, physical structure, and the mechanical stability of the entire apparatus.

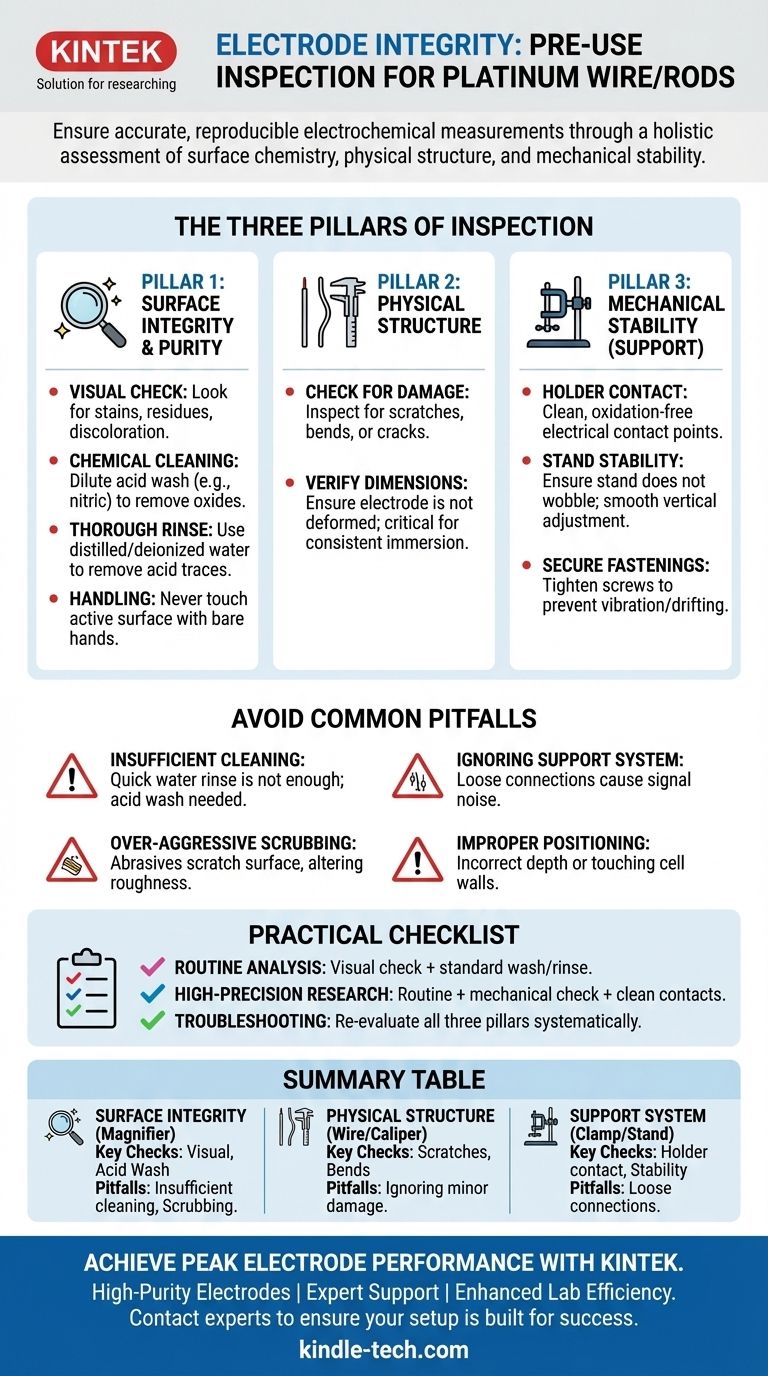

The Three Pillars of Electrode Inspection

A successful electrochemical measurement depends on a stable and clean interface. Your pre-use inspection protocol should be built on three foundational pillars to ensure this stability.

Pillar 1: Surface Integrity and Chemical Purity

The surface of the electrode is where the electrochemical reaction occurs. Its condition is paramount.

- Visual Inspection for Contaminants: Look closely at the platinum surface for any visible stains, residues, or discoloration. These are often signs of organic or inorganic deposits from previous experiments that will interfere with your measurement.

- Chemical Cleaning: To remove invisible oxides and impurities, the standard procedure is to immerse the electrode in a dilute acid solution (like nitric or sulfuric acid) for a short period.

- Thorough Rinsing: Following the acid wash, you must rinse the electrode thoroughly with distilled or deionized water to remove all traces of the acid. Any remaining acid will alter the electrolyte's composition.

- Handling Precautions: Never touch the active surface of the electrode with your bare hands. Oils and salts from your skin are significant sources of contamination.

Pillar 2: Physical Structure of the Electrode

Physical damage can alter the electrode's effective surface area and create inconsistencies in your data.

- Check for Damage: Inspect the wire or rod for any significant scratches, bends, or cracks. Deep scratches increase the microscopic surface area, which can affect current density calculations.

- Verify Dimensions: For experiments where the immersed area is critical, ensure the electrode is not deformed. A bent rod can lead to incorrect and inconsistent immersion depths between runs.

Pillar 3: Mechanical Stability of the Support System

The electrode does not work in isolation. The holder and stand that position it are just as critical to the integrity of the measurement.

- Holder and Electrical Contact: Check that the electrode holder's clip opens and closes correctly. Critically, ensure the conductive contact points within the holder are clean and free of oxidation or grease for a reliable electrical connection.

- Stand and Positioning: Verify that the electrode stand is stable and does not wobble. The vertical adjustment mechanism should slide smoothly, allowing for precise and repeatable positioning of the electrode within the electrolyte.

- Secure Fastenings: Ensure all fastening screws on the holder and stand are tight. Any looseness can lead to vibrations or drifting electrode position during the measurement, which will introduce noise and error into your data.

Understanding Common Pitfalls

Even with a checklist, it's easy to make mistakes that compromise data quality. Being aware of these pitfalls is key to developing a robust experimental technique.

Pitfall: Insufficient Cleaning

A quick rinse in water is not enough. Platinum readily forms a thin oxide layer in air, which can alter its electrochemical potential. An acid wash is necessary to strip this layer and provide a pure platinum surface.

Pitfall: Over-Aggressive Cleaning

While cleaning is crucial, avoid using abrasive materials or harsh physical scrubbing. This will scratch the platinum surface, altering its roughness factor and making your measurements inconsistent and difficult to reproduce.

Pitfall: Ignoring the Support System

Focusing only on the electrode is a common oversight. A loose holder screw or a dirty electrical contact can introduce more error than a slightly contaminated electrode. The entire mechanical and electrical path must be secure.

Pitfall: Improper Positioning and Environment

During setup, ensure the electrode is immersed to the correct depth and is not touching the walls of the electrochemical cell or any other electrodes. This prevents short-circuiting and edge effects. Likewise, shield your setup from mechanical vibrations or strong electromagnetic fields.

A Practical Checklist for Reliable Measurements

Use the following guidelines to tailor your inspection to your specific needs.

- If your primary focus is routine analysis: Perform a visual check for damage and contamination, followed by a standard acid wash and deionized water rinse protocol before every set of experiments.

- If your primary focus is high-precision research: In addition to the standard cleaning, meticulously inspect all mechanical components of the holder and stand for stability and clean the electrical contacts. Consider advanced conditioning, like gentle preheating, if maximum performance stability is required.

- If you are troubleshooting inconsistent results: Systematically re-evaluate all three pillars. A hidden issue in the surface purity, physical structure, or mechanical stability is almost always the root cause of unreliable data.

Adopting this comprehensive inspection protocol is the first and most critical step toward ensuring the accuracy and reproducibility of your electrochemical work.

Summary Table:

| Inspection Pillar | Key Checks | Common Pitfalls to Avoid |

|---|---|---|

| Surface Integrity | Visual check for stains; Acid wash & rinse | Insufficient cleaning; Over-aggressive scrubbing |

| Physical Structure | Check for scratches, bends, or deformation | Ignoring minor damage that alters surface area |

| Support System | Verify holder contact, stand stability, fastenings | Loose connections causing signal noise or drift |

Achieve Peak Electrode Performance with KINTEK

Ensuring your platinum electrodes are in optimal condition is critical for reproducible and accurate electrochemical measurements. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to the precise needs of researchers and technicians.

- High-Purity Electrodes & Accessories: Source reliable platinum electrodes and dedicated cleaning solutions from a trusted supplier.

- Expert Support: Get guidance on proper maintenance protocols and troubleshooting to extend the life of your equipment.

- Enhanced Lab Efficiency: Minimize experimental error and maximize data integrity with the right tools and knowledge.

Don't let electrode inconsistency compromise your research. Contact our experts today to discuss your specific laboratory requirements and ensure your setup is built for success.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Gold Disc Electrode

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- What is the difference between ring disk electrode and rotating disk electrode? Unlock Deeper Electrochemical Insights

- What is the difference between RDE and RRDE? Unlock Advanced Electrochemical Reaction Analysis

- What is the rotating ring disk electrode method? Unlock Real-Time Reaction Analysis

- What is the RRDE in electrochemistry? Unlock Detailed Reaction Pathways with Dual-Electrode Analysis

- What is the application of RRDE? Unlock Quantitative Catalyst and Reaction Insights