At its core, a batch furnace is an industrial oven that processes materials one discrete group, or "batch," at a time. It operates as a completely sealed system; once the material is loaded and the door is closed, the heating chamber is isolated from the outside environment. This design allows for extremely precise control over the entire thermal process from start to finish.

The defining characteristic of a batch furnace is not just its ability to heat materials, but its function as a sealed, isolated environment. This isolation is what enables the high degree of process control required for sensitive applications like cleanroom manufacturing and inert atmosphere heat treating.

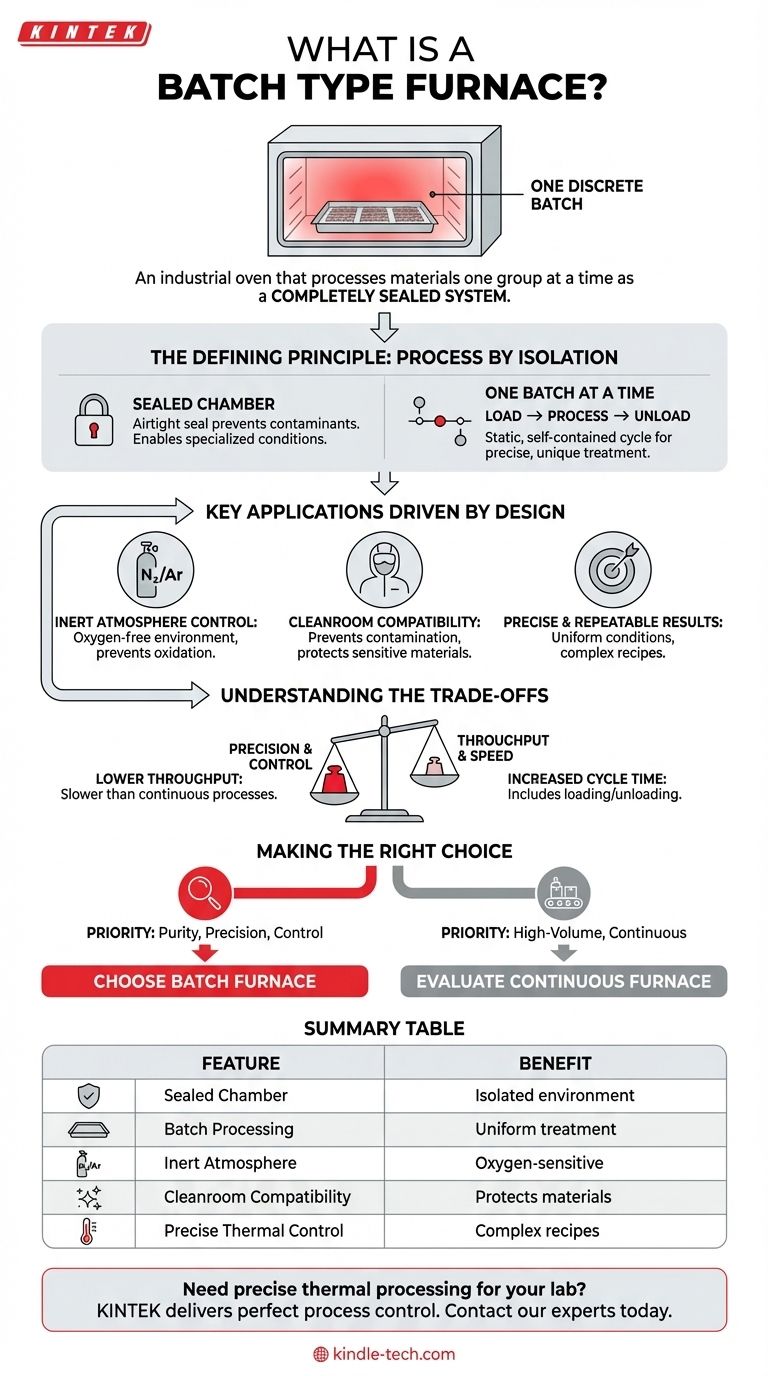

The Defining Principle: Process by Isolation

The fundamental concept behind a batch furnace is processing by isolation. Unlike a continuous furnace where materials are constantly moving through, the batch process is static and self-contained.

Sealing the Chamber

When a batch furnace door is closed, it creates an airtight seal. This ensures that no external contaminants, such as oxygen or dust, can enter the chamber during the heating cycle.

This seal is critical for creating specialized processing conditions that would be impossible in an open system.

One Batch at a Time

The term "batch" refers to a specific quantity of material that is loaded, processed, and unloaded as a single unit. The entire thermal cycle—heating, soaking at a specific temperature, and cooling—is completed for one batch before the next one is introduced.

This stop-and-start nature allows each batch to receive a unique and precisely controlled treatment.

Key Applications Driven by Design

The sealed, static design of a batch furnace makes it the ideal choice for applications where process integrity and precision are paramount.

Inert Atmosphere Control

Because the chamber is sealed, it's possible to purge the ambient air and backfill it with an inert gas like nitrogen or argon. This creates an oxygen-free environment, which is essential for preventing oxidation on metal parts during processes like brazing or annealing.

Cleanroom Compatibility

The sealed design is perfectly suited for cleanroom environments. It prevents any particles or process byproducts from escaping the furnace and contaminating the cleanroom, while also protecting the sensitive materials inside from the external environment.

Precise and Repeatable Results

The batch method allows for complex and highly specific heating "recipes." Since the entire batch is exposed to the same conditions for the same amount of time, it ensures exceptional temperature uniformity and highly repeatable results from one batch to the next.

Understanding the Trade-offs

While powerful, the batch furnace design is not universally optimal. Its primary trade-off is throughput versus precision.

Lower Throughput

The single greatest limitation is production speed. Processing one batch at a time is inherently slower than a continuous furnace that processes a constant stream of material. This makes it less suitable for high-volume, standardized manufacturing.

Increased Cycle Time

The total time per part includes not only the heating cycle but also the time required for loading, unloading, and potentially cooling the furnace between batches. This can significantly extend the overall production timeline compared to a continuous process.

Making the Right Choice for Your Process

Selecting the correct furnace type depends entirely on the specific goals of your thermal process.

- If your primary focus is process purity, precision, and atmosphere control: A batch furnace is the superior choice due to its sealed chamber and ability to deliver highly repeatable results.

- If your primary focus is high-volume, continuous production: You should evaluate a continuous furnace, as the start-stop nature of a batch process may become a production bottleneck.

Ultimately, choosing a batch furnace is a decision to prioritize perfect process control over maximum production speed.

Summary Table:

| Feature | Benefit |

|---|---|

| Sealed Chamber | Creates an isolated environment, preventing contamination and enabling atmosphere control. |

| Batch Processing | Processes one discrete load at a time, ensuring uniform treatment and repeatable results. |

| Inert Atmosphere Capability | Ideal for oxygen-sensitive processes like brazing and annealing. |

| Cleanroom Compatibility | Protects sensitive materials and the external environment from cross-contamination. |

| Precise Thermal Control | Allows for complex heating "recipes" with exceptional temperature uniformity. |

Need precise thermal processing for your lab?

A batch furnace from KINTEK delivers the perfect process control your sensitive applications demand. Our expertise in lab equipment ensures you get a solution tailored for inert atmosphere heat treatment, cleanroom compatibility, and repeatable results.

Let's discuss your specific needs. Contact our experts today to find the ideal batch furnace for your laboratory.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan