In short, a braze repair is a metal-joining process where two or more metal items are joined together by melting and flowing a filler metal into the joint. Critically, the filler metal has a lower melting point than the adjoining metal, meaning the base components are heated but never melted. This process creates a strong, permanent, and often seamless bond through a metallurgical principle called capillary action.

Braze repair is not simply “gluing” metals together. It is a precise metallurgical process that creates a bond that can be as strong, or even stronger, than the original metals, all without the high heat and distortion associated with welding. The secret lies in a clean surface, a tight fit, and the power of capillary action.

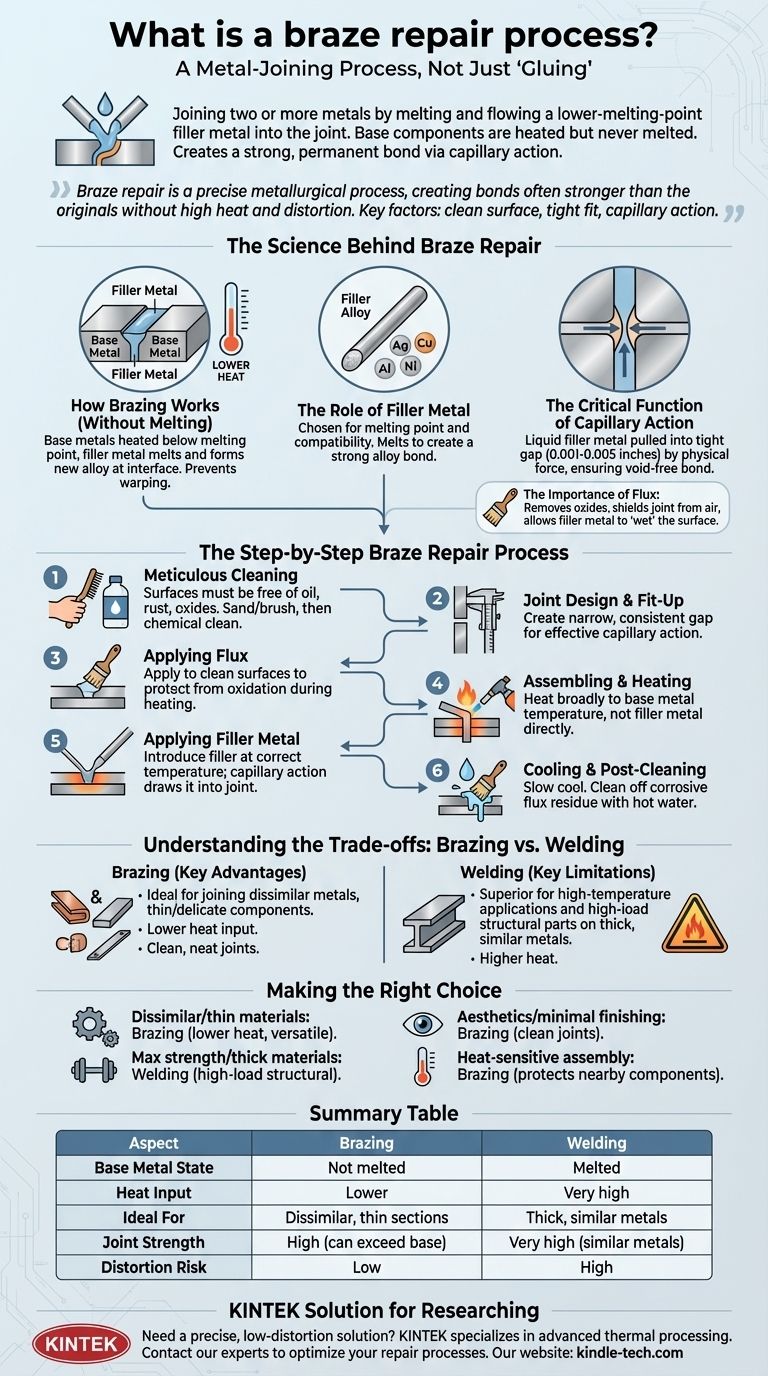

The Science Behind Braze Repair

To truly understand braze repair, you must look beyond the torch and filler rod. The process relies on a few core scientific principles working in concert to form a durable bond.

How Brazing Works (Without Melting)

The fundamental difference between brazing and welding is the state of the base metal (the parts being repaired). In brazing, the base metals are heated to a temperature high enough to melt the filler metal, but always below their own melting point. This lower heat input is crucial, as it prevents warping, distortion, and changes to the base metal's inherent properties.

The Role of Filler Metal

The filler metal, often an alloy of silver, copper, aluminum, or nickel, is the hero of the process. It's chosen based on its melting temperature and its compatibility with the base metals. When it melts, it interacts with the surface of the hot base metal to form a new, strong alloy at the interface.

The Critical Function of Capillary Action

Brazing derives its exceptional strength from capillary action. This is the physical force that pulls a liquid into a very narrow space. For a braze repair to succeed, the joint must have a very tight, uniform gap (typically 0.001 to 0.005 inches). When the molten filler metal is introduced, this capillary force pulls it deep into the entire joint, ensuring complete coverage and a void-free bond.

The Importance of Flux

A metal surface, even if it looks clean, is covered in a layer of oxide that will prevent the filler metal from bonding. Flux is a chemical cleaning agent applied before heating. As it heats up, it removes these oxides and shields the joint from the air, allowing the molten filler metal to "wet" the surface and flow correctly.

The Step-by-Step Braze Repair Process

A successful braze repair is less about brute force and more about methodical preparation. Each step is critical to the final outcome.

Step 1: Meticulous Cleaning

This is the most important step. The joint surfaces must be absolutely free of oil, grease, rust, and oxides. This is achieved through mechanical methods like sanding or wire brushing, followed by a chemical cleaning with a solvent.

Step 2: Joint Design and Fit-Up

The parts must be arranged to create a narrow, consistent gap. The strength of the final joint is directly dependent on maintaining the correct clearance for capillary action to work effectively.

Step 3: Applying Flux

Flux is applied to the clean joint surfaces of both parts before assembly. This ensures the entire bond area is protected from oxidation during heating.

Step 4: Assembling and Heating the Joint

The parts are assembled and held in place. The entire assembly is then heated broadly and uniformly with a torch. The goal is to bring the base metals up to the filler metal's melting temperature, not to heat the filler metal directly.

Step 5: Applying the Filler Metal

Once the assembly is at the correct temperature (often indicated by the flux becoming clear and liquid), the filler rod is touched to the edge of the joint. The heat from the base metals will instantly melt the rod, and capillary action will draw the liquid metal into and throughout the joint.

Step 6: Cooling and Post-Cleaning

The assembly is allowed to cool slowly and naturally to prevent thermal stress. Once cool, any remaining flux residue, which is often corrosive, must be thoroughly cleaned off with hot water and brushing.

Understanding the Trade-offs: Brazing vs. Welding

Brazing is a powerful tool, but it's not a universal solution. Knowing when to use it versus welding is key to a successful repair.

When to Choose Brazing: Key Advantages

Brazing excels where welding falters. Its primary advantage is the ability to join dissimilar metals, such as copper to steel or carbide to steel. The lower heat input also makes it ideal for thin or delicate components that would be destroyed by welding, and it produces a clean, neat joint that often requires no finishing.

When Welding Might Be Better: Key Limitations

The primary limitation of a brazed joint is its service temperature, which is governed by the melting point of the filler alloy. For high-temperature applications, welding is superior. Furthermore, while a well-designed brazed joint is incredibly strong, a properly executed weld on thick, identical metals will generally have higher tensile and shear strength for extreme load-bearing structural parts.

Making the Right Choice for Your Repair

Your choice between brazing, welding, or another method should be driven by the specific demands of the component and its application.

- If your primary focus is joining dissimilar metals or thin materials: Brazing is often the superior choice due to its lower heat input and material versatility.

- If your primary focus is maximum strength on thick, similar metals: A properly executed weld will typically provide a stronger joint for high-load structural applications.

- If your primary focus is aesthetics and minimal finishing: Brazing produces clean, neat joints that require little to no grinding or polishing.

- If your primary focus is repairing a heat-sensitive assembly: The low heat of brazing protects nearby components and preserves the base metal's original properties.

By understanding the principles of braze repair, you can confidently select the most effective and durable solution for your specific metal repair challenge.

Summary Table:

| Aspect | Brazing | Welding |

|---|---|---|

| Base Metal State | Not melted | Melted |

| Heat Input | Lower | Very high |

| Ideal For | Dissimilar metals, thin sections | Thick, similar metals |

| Joint Strength | High (can exceed base metal) | Very high (on similar metals) |

| Distortion Risk | Low | High |

Need a precise, low-distortion solution for your metal components?

At KINTEK, we specialize in advanced thermal processing solutions for laboratory and industrial applications. Whether you're joining dissimilar metals or repairing delicate parts, our expertise in brazing and heat treatment can help you achieve strong, reliable bonds without compromising your base materials.

Contact our experts today to discuss how our lab equipment and consumables can optimize your repair and joining processes.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What's the difference between hot and cold laminating? Choose the Right Method for Your Document

- How does a laboratory magnetic stirrer contribute to pre-mixing? Master Your Photocatalytic Reaction Baselines

- Does pyrolysis produce pollution? Understanding the Environmental Impact of Modern Waste Conversion

- Are lab grown diamonds used for industry? The Unmatched Choice for Precision and Performance

- What are the four steps to the heat treating process? Master the 3 Core Stages for Superior Results

- What is the most common metal used for blacksmithing? Start with Mild Steel for Forging Success

- Why is an industrial-grade oven required during the final stage of modified H-beta zeolite catalyst preparation?

- What is the function of a crucible furnace? A Guide to Controlled Melting for Casting and Alloying