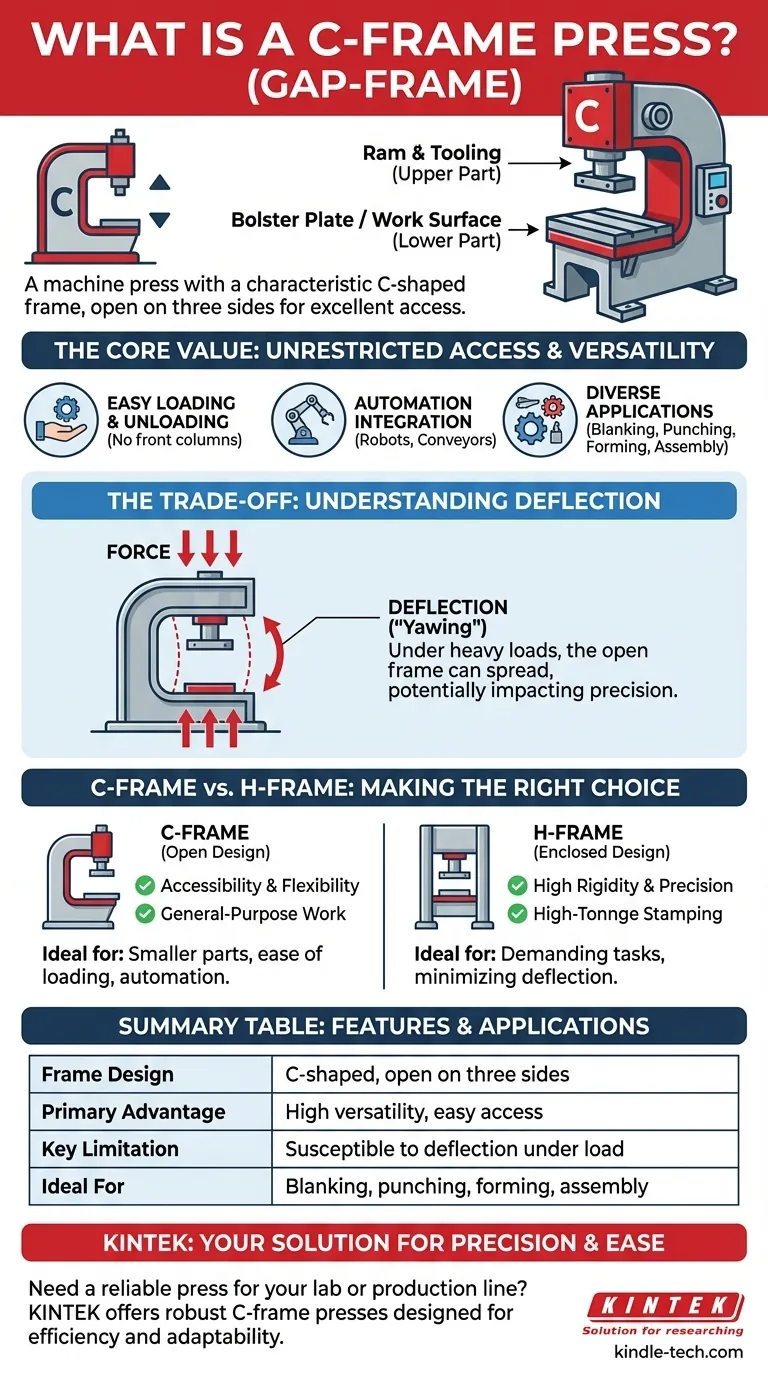

A C-frame press is a type of machine press named for its characteristic C-shaped frame. This design, also known as a gap-frame press, is intentionally open on three sides (front and both sides). This provides excellent access to the work area, making it highly versatile for a wide range of manufacturing and assembly tasks.

The core value of a C-frame press lies in its open design, which prioritizes accessibility and operational flexibility. However, this same design introduces a fundamental trade-off between accessibility and the absolute rigidity found in closed-frame press designs.

The Defining Characteristic: An Open Design

The entire functionality and application of a C-frame press stem from its unique, accessible structure.

The "C" Shape Explained

The frame of the press is a single, solid structure that resembles the letter "C". The ram and tooling are housed in the upper part of the "C," while the bolster plate or work surface sits on the lower part.

Unrestricted Access

Because the frame is only connected at the back (the spine of the "C"), it is completely open on the front and sides. This frees the operator from the constraints of columns or a closed frame.

This design makes it significantly easier to load and unload parts, set up tooling, and integrate auxiliary equipment like robotic arms or conveyors.

Versatility in Application

The easy access and large working space make the C-frame press suitable for a broad spectrum of operations. Common applications include blanking, punching, drawing, forming, straightening, and assembly.

Understanding the Trade-offs

The open design that makes the C-frame so useful also presents its primary limitation.

The Challenge of Deflection

Under heavy loads, the open "throat" of the C-frame has a natural tendency to spread apart slightly. This phenomenon is known as deflection or "yawing."

While often measured in thousandths of an inch, this deflection can impact the precision of operations that require perfect parallelism between the ram and the press bed.

The Role of Rigid Construction

To counteract this inherent tendency, C-frame presses are engineered with extremely rigid, often integrally welded, structures. This robust construction ensures the frame maintains its integrity and minimizes deflection under its rated tonnage.

C-Frame vs. H-Frame Presses

In contrast, an H-frame press (also known as a straight-side or column press) has a fully enclosed frame. This design offers superior rigidity and resistance to deflection, making it the preferred choice for high-tonnage, high-precision stamping or applications with off-center loads. The trade-off is significantly reduced access to the work area.

Making the Right Choice for Your Goal

Selecting the correct press type depends entirely on the demands of your specific application.

- If your primary focus is accessibility and versatility: The C-frame press is the ideal choice for general-purpose work, smaller parts, and processes where ease of loading and automation is critical.

- If your primary focus is high-tonnage precision and minimizing deflection: An H-frame or straight-side press is better suited for demanding tasks like heavy stamping, coining, and deep-drawing operations.

Ultimately, the C-frame press represents an exceptional balance of power and flexibility, making it a cornerstone of modern fabrication and assembly when applied to the right tasks.

Summary Table:

| Feature | Description |

|---|---|

| Frame Design | C-shaped, open on three sides for excellent access |

| Primary Advantage | High versatility and ease of part loading/unloading |

| Key Limitation | Susceptible to deflection under heavy loads |

| Ideal For | Blanking, punching, forming, assembly, and automation integration |

| Best Suited When | Accessibility and operational flexibility are top priorities |

Need a reliable press for your lab or production line? KINTEK specializes in lab equipment and consumables, offering robust C-frame presses designed for precision and ease of use. Whether you're in manufacturing, research, or assembly, our presses enhance efficiency and adaptability. Contact us today to find the perfect solution for your needs!

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Automatic Laboratory Heat Press Machine

People Also Ask

- What advantages does a Cold Isostatic Press (CIP) offer for solid-state batteries? Superior Density & Uniformity

- What is CIP in powder metallurgy? Unlock Uniform Density for Complex Parts

- What are the disadvantages of cold isostatic pressing? Key Limitations in Dimensional Accuracy & Speed

- What is the process of cold isostatic pressing? Achieve Uniform Density in Complex Parts

- What is cold isostatic pressing of metal powder? Achieve Uniform Density in Complex Metal Parts