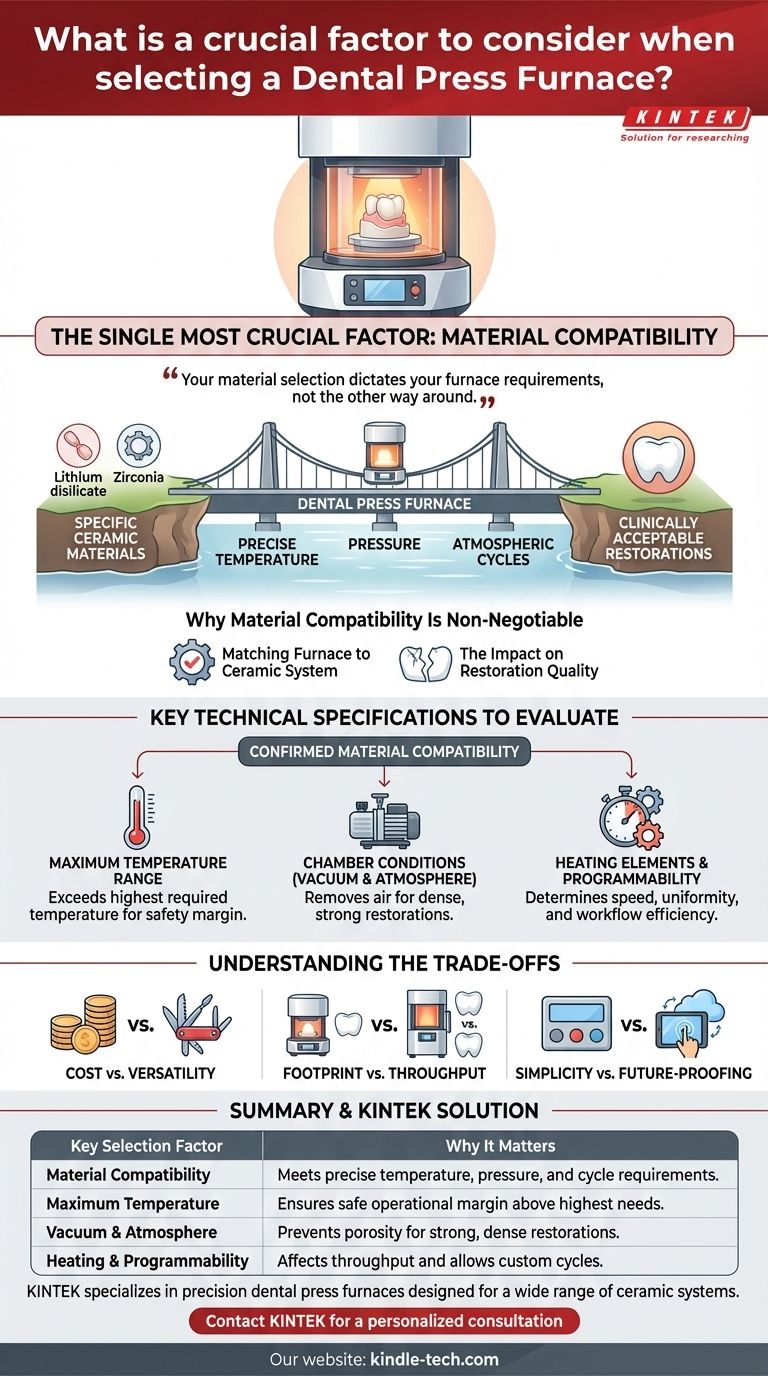

Without question, the single most crucial factor to consider when selecting a Dental Press Furnace is its verified capability to process the specific ceramic materials you intend to use. Every other technical specification flows from this primary requirement, as the furnace must be able to execute the precise temperature, pressure, and atmospheric cycles demanded by your chosen materials to produce clinically acceptable restorations.

A Dental Press Furnace is a long-term investment in your lab's capabilities. The decision should not be driven by the furnace's features, but rather by the demands of the materials you use. Your material selection dictates your furnace requirements, not the other way around.

Why Material Compatibility Is Non-Negotiable

A dental press furnace is a specialized piece of equipment that applies high temperatures and pressure to press, sinter, or glaze ceramic materials into their final hardened state for restorations like inlays, onlays, and bridges. Its entire purpose is to transform a raw material into a precise, durable, and aesthetic final product.

Matching Furnace to Ceramic System

Different ceramic systems, such as lithium disilicate or zirconia-based materials, have unique and non-negotiable processing parameters. Each material has a specific temperature curve it must follow for heating, pressing, and cooling.

A furnace that cannot precisely hit and maintain these required temperatures will fail to produce a viable restoration.

The Impact on Restoration Quality

Failure to match the furnace's capabilities to the material's needs directly compromises the physical and aesthetic properties of the final restoration. This can lead to issues with strength, fit, color, and translucency, ultimately resulting in remakes that cost time and money.

Key Technical Specifications to Evaluate

Once you have confirmed a furnace is compatible with your primary materials, you can evaluate the technical specifications that determine its performance, efficiency, and versatility.

Maximum Temperature Range

This is the most fundamental specification after material compatibility. You must ensure the furnace's maximum temperature exceeds the highest processing temperature required by any material you plan to use, providing a safe operational margin.

Chamber Conditions: Vacuum and Atmosphere

Properly firing ceramics requires a controlled environment. A vacuum pump is essential for removing air from the muffle during the heating cycle, which prevents porosity and ensures a dense, strong final restoration. The level of vacuum the system can achieve is a critical performance metric.

Heating Elements and Speed

The type and quality of the heating elements (e.g., quartz, silicon carbide) determine the furnace's heating rate, temperature uniformity, and service life. Faster heating and cooling cycles can significantly increase a lab's throughput and efficiency.

Control System and Programmability

Modern furnaces feature sophisticated control systems. Look for units with pre-installed programs for common materials, which simplifies workflow and reduces errors. The ability to create and save custom programs is also vital for labs that work with a variety of materials or wish to fine-tune their processes.

Understanding the Trade-offs

Choosing the right furnace involves balancing capabilities with practical constraints. Being aware of these trade-offs is key to making a sound investment.

Cost vs. Versatility

Furnaces with broader temperature ranges, more precise vacuum control, and extensive programmability will carry a higher price tag. A lab specializing in a single material may not need the versatility that a full-service lab requires.

Footprint vs. Throughput

The physical size of the furnace is an important consideration for any lab. Larger units may offer higher throughput by accommodating more restorations per cycle, but they require more bench space.

Simplicity vs. Future-Proofing

Some furnaces are designed for extreme simplicity, focusing on a narrow range of common materials. While easy to use, they may not accommodate new ceramic materials that come to market. A more programmable furnace offers a degree of future-proofing for your lab's capabilities.

Making the Right Choice for Your Lab

Your final decision should be a strategic one, based on the specific goals and workflow of your dental practice or laboratory.

- If your primary focus is a single, high-volume material: Choose a furnace that is specifically optimized and pre-programmed for that material's firing cycle to ensure consistency and ease of use.

- If your primary focus is working with a wide variety of ceramics: Invest in a furnace with a broad temperature range, excellent vacuum control, and extensive custom programmability.

- If your primary focus is maximizing lab efficiency and throughput: Prioritize models with faster heating/cooling cycles and larger chamber capacities to handle more restorations per day.

Ultimately, selecting the right dental press furnace is about aligning the equipment's technical capabilities with your clinical and business objectives.

Summary Table:

| Key Selection Factor | Why It Matters |

|---|---|

| Material Compatibility | The furnace must meet the precise temperature, pressure, and cycle requirements of your specific ceramics (e.g., lithium disilicate). |

| Maximum Temperature | Must exceed the highest processing temperature of your materials for a safe operational margin. |

| Vacuum & Atmosphere Control | Prevents porosity, ensuring dense, strong final restorations. |

| Heating Rate & Programmability | Affects lab throughput and allows for custom cycles for different materials. |

Ensure your lab's success with the right equipment.

Choosing a dental press furnace is a significant investment in the quality and efficiency of your laboratory. The right furnace, matched perfectly to your material needs, is crucial for producing strong, aesthetic, and clinically acceptable dental restorations every time.

KINTEK specializes in precision lab equipment, including dental press furnaces designed for a wide range of ceramic systems. Our experts can help you select a furnace that aligns with your specific materials, workflow, and business goals, ensuring you get the performance and reliability your lab deserves.

Contact KINTEK today for a personalized consultation and let us help you make an informed decision that will enhance your lab's capabilities for years to come.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results