While a specific zirconia sintering furnace might be listed at a price point, the true cost varies significantly based on its technical capabilities and intended use. For example, one model is priced at ₹550,000 (approximately $6,600 USD), but this represents just a single point in a wide spectrum of options available to dental labs and material scientists.

The purchase of a zirconia sintering furnace is less about finding the lowest price and more about investing in the specific technical capabilities required for your work. Key factors like temperature control, chamber uniformity, and cycle speed directly dictate the furnace's cost and, more importantly, the quality and consistency of your results.

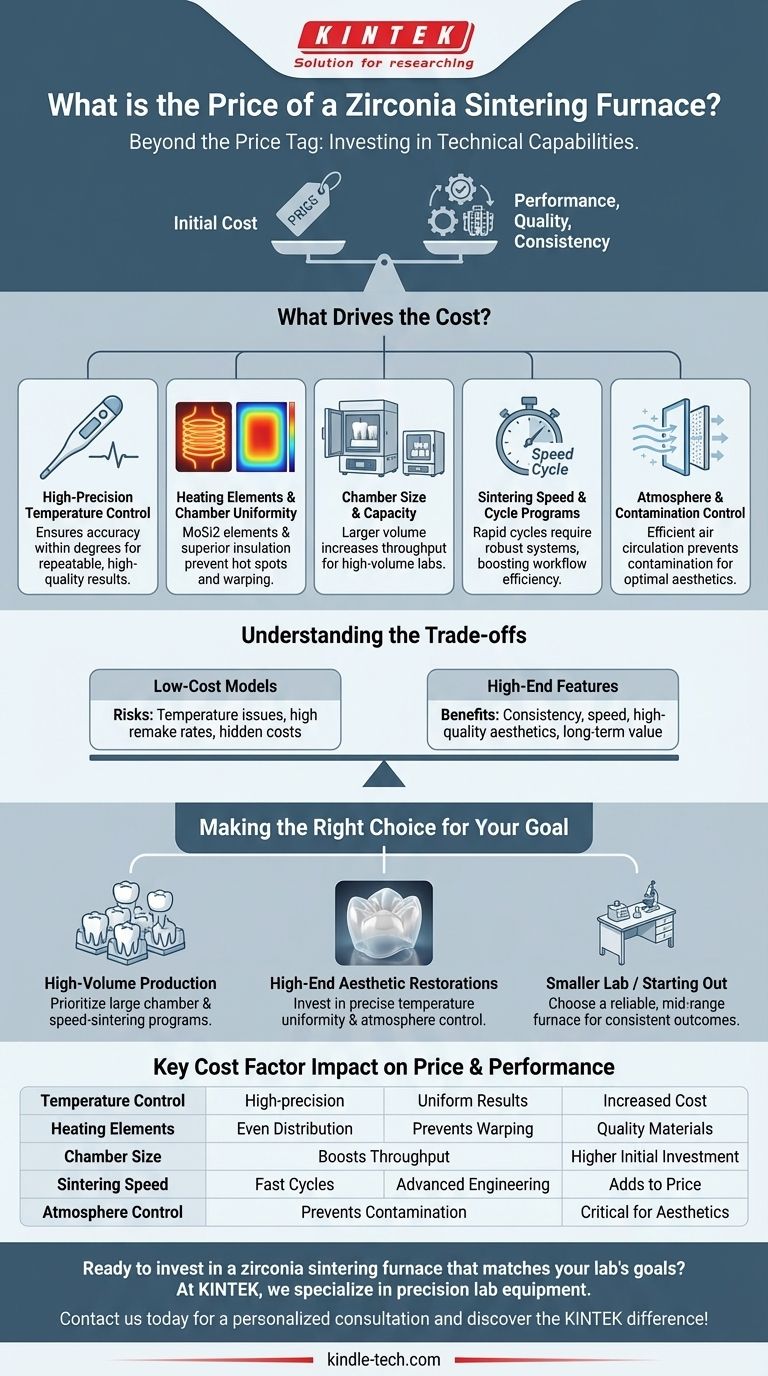

What Drives the Cost of a Zirconia Sintering Furnace?

The price tag of a furnace is a direct reflection of its engineering and the precision it can deliver. Understanding these core components allows you to evaluate whether a furnace's cost is justified for your needs.

High-Precision Temperature Control

A furnace's primary job is to follow a precise temperature curve. A high-quality temperature controller is non-negotiable for achieving the correct material properties in zirconia.

Less expensive furnaces may have temperature fluctuations, leading to weak or aesthetically flawed restorations. Premium models ensure accuracy within just a few degrees, guaranteeing repeatable results.

Heating Elements and Chamber Uniformity

The type and quality of heating elements are critical. Most high-quality furnaces use Molybdenum Disilicide (MoSi2) elements capable of reaching and sustaining high temperatures without degrading.

These advanced elements, combined with superior insulation, create even heat distribution throughout the chamber. This prevents "hot spots" that can cause warping or inconsistent sintering across a batch of restorations.

Chamber Size and Capacity

The internal volume of the furnace chamber directly impacts its price. A larger chamber allows a high-volume lab to sinter more units in a single cycle, increasing throughput and efficiency.

For smaller labs, a large, expensive chamber may be an unnecessary expense if its full capacity is rarely used.

Sintering Speed and Cycle Programs

Standard sintering cycles can take several hours. Many modern, higher-priced furnaces offer "speed" sintering cycles that can be completed in a fraction of the time.

This capability requires more robust heating elements and sophisticated control systems to manage rapid temperature changes, adding to the cost but offering significant workflow advantages.

Atmosphere and Contamination Control

Zirconia's final shade and translucency can be affected by atmospheric contaminants during sintering.

An efficient air circulation system, as noted in furnace specifications, helps purge these contaminants and ensures a clean environment. This feature is vital for producing high-end aesthetic restorations and is a hallmark of a well-engineered furnace.

Understanding the Trade-offs

Choosing a furnace involves balancing cost against performance. A lower initial investment can sometimes lead to higher long-term costs.

Low-Cost Models: The Hidden Risks

Inexpensive furnaces often compromise on temperature uniformity and control. This can lead to a higher rate of failed restorations that are either structurally weak or do not match the desired shade.

The cost of materials and labor for remakes can quickly erase the initial savings from a cheaper furnace.

High-End Features: Are They Worth It?

Features like massive capacity or ultra-fast speed cycles are valuable only if your workflow demands them. A small lab focused on highly detailed, single-unit aesthetic cases may benefit more from exceptional temperature accuracy than from raw speed.

Objectively assess your daily production needs to avoid over-investing in capabilities you will not use.

Making the Right Choice for Your Goal

Select a furnace based on a clear understanding of your lab's primary objectives.

- If your primary focus is high-volume production: Prioritize a furnace with a larger chamber capacity and proven speed-sintering programs to maximize your daily throughput.

- If your primary focus is high-end aesthetic restorations: Invest in a model renowned for its precise temperature uniformity and atmosphere control to ensure consistent, predictable results.

- If you are a smaller lab or just starting out: A reliable, mid-range furnace with a reputation for accuracy is a smarter investment than a low-cost unit that risks inconsistent outcomes.

Ultimately, the right furnace is an investment in the consistency, quality, and reputation of your work.

Summary Table:

| Key Cost Factor | Impact on Price & Performance |

|---|---|

| Temperature Control | High-precision controllers ensure uniform sintering and consistent results, increasing cost. |

| Heating Elements | MoSi2 elements and superior insulation provide even heat distribution, preventing warping. |

| Chamber Size | Larger chambers boost throughput but raise the initial investment. |

| Sintering Speed | Fast-cycle programs require advanced engineering, adding to the price. |

| Atmosphere Control | Efficient air circulation systems prevent contamination, critical for aesthetic restorations. |

Ready to invest in a zirconia sintering furnace that matches your lab's goals? At KINTEK, we specialize in providing precision lab equipment tailored to dental labs and material scientists. Whether you need high-volume production capabilities or exceptional temperature control for aesthetic restorations, our experts will help you select the right furnace to enhance your workflow and ensure consistent, high-quality results. Contact us today for a personalized consultation and discover the KINTEK difference!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations