In short, a dental burnout furnace is a specialized, high-temperature oven used in a dental laboratory to melt and eliminate wax or resin patterns from a ceramic investment mold. This critical step, known as the "burnout" process, creates a clean and perfectly detailed negative space within the mold. This cavity is then filled with a molten alloy or pressed with ceramic to fabricate precise dental restorations like crowns, bridges, and implant components.

The core purpose of a burnout furnace is not simply to apply heat. It is a precision instrument designed for the controlled, clean, and complete removal of a temporary pattern, ensuring the resulting mold is flawless. The accuracy of this single step directly determines the fit, quality, and ultimate success of the final dental restoration.

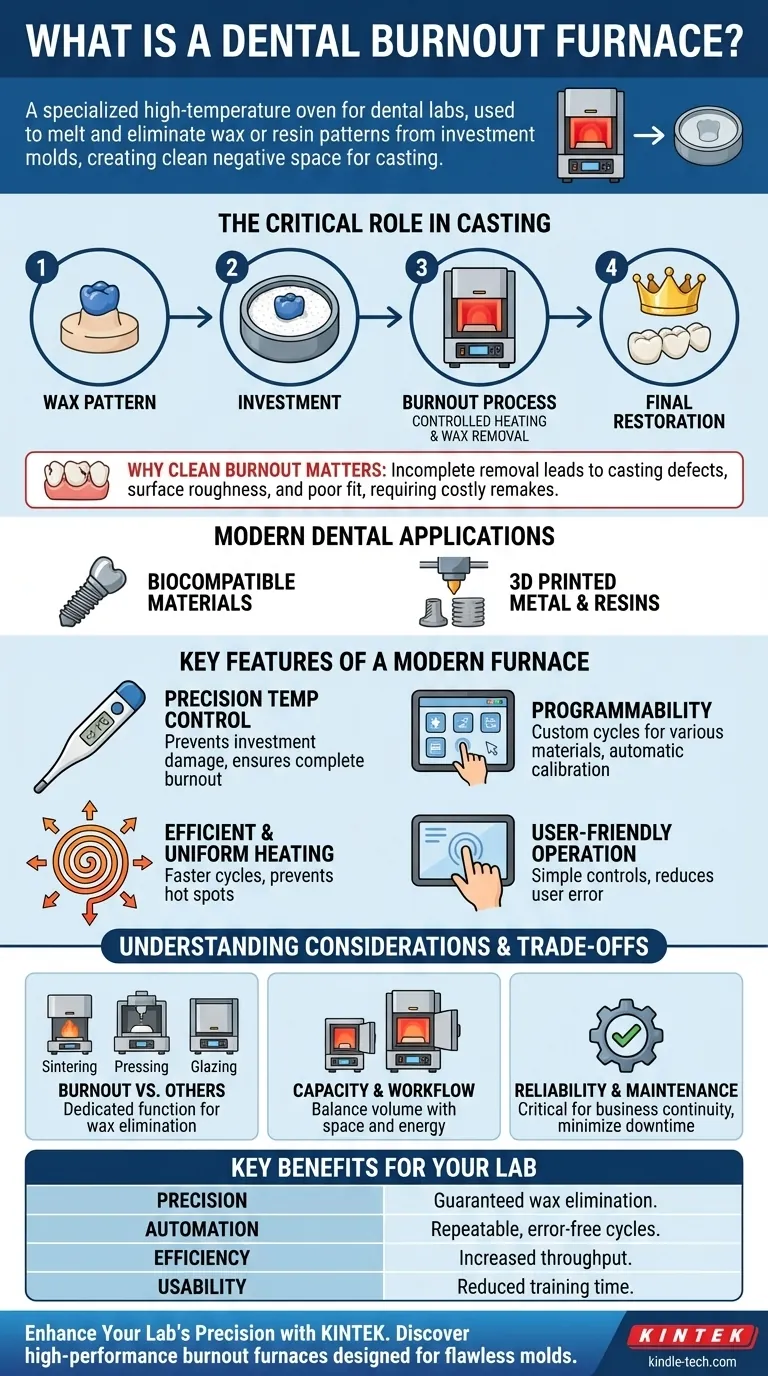

The Critical Role in the Casting Process

A burnout furnace is a cornerstone of the "lost-wax" casting technique, a process that has been refined for centuries and remains fundamental to modern dentistry. The quality of the furnace's performance has a direct impact on lab efficiency and patient outcomes.

From Wax Pattern to Final Product

The process begins with a wax model of the final restoration. This wax pattern is placed inside a ring and surrounded by a liquid ceramic material called an investment.

Once the investment hardens, the entire ring is placed into the burnout furnace. The furnace executes a precise heating cycle that melts the wax, which then flows or vaporizes out of the mold, leaving a hollow cavity that is an exact negative of the original pattern.

Why Clean and Complete Burnout is Paramount

The goal is to leave behind a clean and precise mold, free from any carbon residue or distortion. Incomplete burnout can lead to casting porosity, surface roughness, or dimensional inaccuracies.

These defects compromise the fit and aesthetics of the final restoration. A poorly fitting crown or implant can cause discomfort, lead to further dental issues, and require a costly remake, wasting both time and materials.

Modern Dental Applications

While traditionally used for casting metal alloys, burnout furnaces are essential for a range of modern applications. This includes creating molds for biocompatible materials like titanium and for heat-treating restorations created with 3D metal printers. They are a key component in producing consistently accurate and high-quality dental implant components.

Key Features of a Modern Burnout Furnace

Modern furnaces are sophisticated devices engineered for precision, reliability, and ease of use. Their features are designed to eliminate variables and produce consistent results.

Precision Temperature Control

This is the most critical feature. High-quality furnaces offer automatic temperature adjustment with an error margin often as low as +/- 1°C. This precision prevents damage to the investment material and ensures the wax is eliminated completely at the optimal temperature.

Programmability and Automation

Technicians can use a digital touch screen to run pre-set or custom programs for different types of waxes, resins, and investment materials. Features like automatic temperature calibration before each cycle ensure repeatability and remove guesswork from the process.

Efficient and Uniform Heating

A high heating rate reduces the overall processing time, allowing a lab to handle more cases and optimize its workflow. Many furnaces use a spiral quartz chamber to ensure heat is distributed evenly, preventing hot spots that could damage the mold.

User-Friendly Operation

Modern design emphasizes simplicity. Intuitive displays, simple controls, and features like a USB port for computer connectivity make operation and service straightforward, reducing the chance of user error.

Understanding the Trade-offs and Considerations

While burnout is its primary function, it's important to understand how these furnaces fit into the broader context of a dental lab's equipment.

Burnout vs. Other Furnace Types

The term "dental furnace" is broad. While a burnout furnace is for wax elimination, other specialized furnaces exist for sintering (hardening zirconia), pressing (shaping pressable ceramics), and glazing (firing a final glassy layer). Some multi-function units exist, but dedicated burnout furnaces are optimized for that specific, critical task.

Capacity and Workflow Impact

The size of the furnace chamber determines its capacity—how many casting rings it can process at once. A larger furnace increases throughput but also has a larger physical footprint and higher energy consumption. Labs must balance their daily case volume against available space and budget.

Reliability and Maintenance

A furnace failure can bring a lab's entire crown and bridge production to a halt. For this reason, models designed with optimized control circuits, low failure rates, and easy routine maintenance are highly valued. Reliability is not a luxury but a requirement for business continuity.

Making the Right Choice for Your Lab

Selecting the right furnace requires analyzing your specific production goals and priorities.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber capacity and rapid, efficient heating cycles to maximize daily throughput.

- If your primary focus is high-precision implant and cosmetic cases: Focus on a furnace with the most accurate temperature control and advanced programming capabilities to guarantee flawless molds.

- If your primary focus is efficiency in a smaller lab: A compact, reliable furnace with a user-friendly interface and proven, pre-set programs will deliver the best return on investment.

Ultimately, investing in a high-quality burnout furnace is a direct investment in the precision, quality, and reputation of your laboratory's work.

Summary Table:

| Key Feature | Benefit for Your Lab |

|---|---|

| Precision Temperature Control (+/- 1°C) | Guarantees complete wax elimination and protects the investment mold. |

| Programmability & Automation | Ensures repeatable, error-free cycles for different materials. |

| Efficient & Uniform Heating | Increases throughput and prevents mold damage from hot spots. |

| User-Friendly Operation | Reduces training time and minimizes the risk of user error. |

Ready to enhance the precision and efficiency of your dental lab?

A high-performance burnout furnace from KINTEK is a direct investment in the quality of your crowns, bridges, and implant components. Our specialized lab equipment is designed to deliver the flawless molds you need for perfect-fitting restorations, case after case.

Contact KINTEK today to find the perfect burnout furnace solution for your laboratory's specific workflow and volume needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations