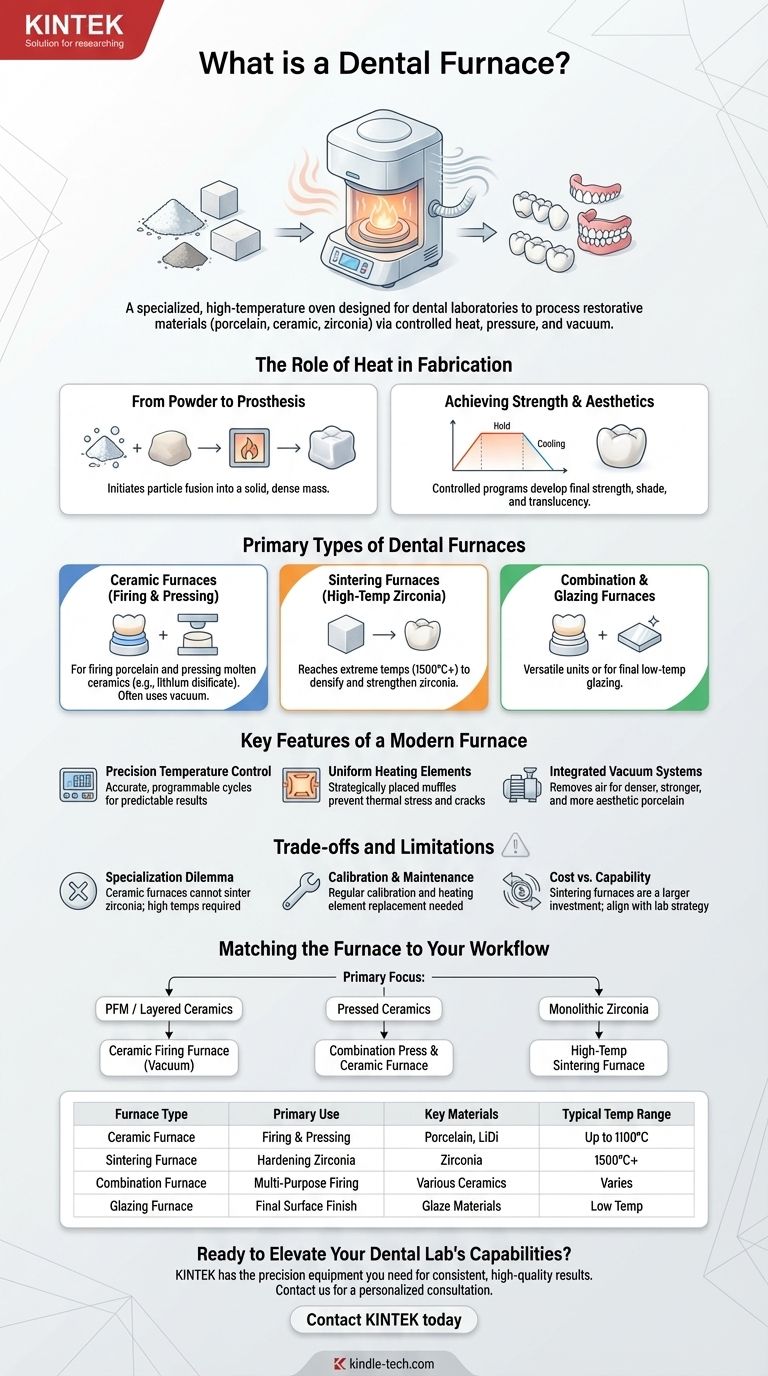

At its core, a dental furnace is a specialized, high-temperature oven designed for use in dental laboratories. It is the essential equipment used to process advanced restorative materials like porcelain, ceramic, and zirconia. By applying precisely controlled cycles of heat, pressure, and vacuum, a furnace transforms these materials from a raw or partially processed state into strong, durable, and aesthetically pleasing dental restorations such as crowns, bridges, and dentures.

A dental furnace is not a one-size-fits-all device. The critical distinction is between ceramic furnaces, used for firing and pressing traditional porcelains, and sintering furnaces, which reach the much higher temperatures required to fully harden modern zirconia restorations.

The Role of Heat in Dental Fabrication

A dental furnace is the final, critical step in the creation of most indirect dental restorations. Its function is to induce a permanent physical change in the material, giving the prosthesis its final strength, fit, and appearance.

From Powder to Prosthesis

Many ceramic materials begin as a fine powder or a soft, chalk-like block. The furnace initiates a process where these individual particles fuse together into a solid, dense mass. This transformation is what gives the final restoration its structural integrity.

Achieving Strength and Aesthetics

The heating process is not simply about temperature; it is a meticulously controlled program. Specific ramp rates (how quickly temperature rises), hold times, and cooling periods are essential for developing the material's intended strength, shade, and translucency, preventing cracks or warping.

The Primary Types of Dental Furnaces

The type of furnace a laboratory requires is dictated entirely by the materials it intends to work with. Each furnace is engineered for a specific set of processes and temperature ranges.

Ceramic Furnaces (Firing and Pressing)

These are the most traditional types of furnaces. They are designed for firing layers of porcelain onto a metal or ceramic core and for pressing molten ceramic ingots (like lithium disilicate) into a mold. They typically operate with a vacuum to remove air bubbles, creating a denser and more aesthetic result.

Sintering Furnaces (High-Temperature Zirconia)

Sintering furnaces are built to reach the extremely high temperatures (often above 1500°C) required to process zirconia. Zirconia restorations are first milled from a soft, "green state" block. The sintering process shrinks the restoration to its final dimensions and transforms it into one of the strongest materials available in dentistry.

Combination and Glazing Furnaces

A combination furnace is a versatile unit that can handle both the firing and pressing of ceramics, which is ideal for labs working with a variety of materials. A glazing furnace is used for a final, low-temperature firing cycle that applies a smooth, glass-like surface to the restoration, improving its appearance and hygiene.

Key Features of a Modern Furnace

Modern dental furnaces are precision instruments that rely on advanced technology to produce consistent and reliable results.

Precision Temperature Control

The most critical feature is the ability to accurately control temperature throughout the cycle. Digital programmable controllers allow technicians to run specific, manufacturer-recommended programs for each material, ensuring predictable outcomes.

Uniform Heating Elements

High-quality furnaces use heating elements (muffles) placed strategically to ensure the entire restoration heats evenly. This uniformity is vital for preventing thermal stress, which can cause cracks or distortion in the final product.

Integrated Vacuum Systems

For porcelain work, a built-in vacuum pump is essential. By removing air from the firing chamber, the vacuum helps compact the ceramic particles, resulting in a restoration with fewer voids, greater strength, and better translucency.

Understanding the Trade-offs and Limitations

While essential, dental furnaces are specialized pieces of equipment with important distinctions that must be understood to avoid costly errors.

The Specialization Dilemma

A standard ceramic furnace cannot be used to sinter zirconia. The temperature requirements for zirconia are far beyond the capabilities of a ceramic furnace, and attempting to do so will damage the furnace and fail to process the restoration.

Calibration and Maintenance

To maintain accuracy, furnaces require periodic temperature calibration. The heating elements are also consumable components with a limited lifespan that will eventually need to be replaced, representing an ongoing operational cost.

Cost vs. Capability

A high-temperature sintering furnace is a significantly larger investment than a standard ceramic furnace. A laboratory's decision must be based on a clear strategy regarding the materials it will offer to its clients.

Matching the Furnace to Your Workflow

Your choice of furnace must align directly with the specific materials you use and the services you provide.

- If your primary focus is porcelain-fused-to-metal (PFM) or layered ceramics: A reliable ceramic firing furnace with precise vacuum control is your essential tool.

- If your primary focus is pressed ceramics (e.g., lithium disilicate): You need a dedicated combination press and ceramic furnace designed for injecting molten material.

- If your primary focus is monolithic zirconia restorations: A high-temperature sintering furnace is non-negotiable and will be the cornerstone of your digital production workflow.

Ultimately, the dental furnace is the engine that transforms advanced materials into functional, high-quality dental prosthetics, making it a foundational investment for any modern laboratory.

Summary Table:

| Furnace Type | Primary Use | Key Materials | Typical Temperature Range |

|---|---|---|---|

| Ceramic Furnace | Firing & Pressing | Porcelain, Lithium Disilicate | Up to 1100°C |

| Sintering Furnace | Hardening Zirconia | Zirconia | 1500°C and above |

| Combination Furnace | Multi-Purpose Firing | Various Ceramics | Varies by program |

| Glazing Furnace | Final Surface Finish | Glaze Materials | Low Temperature |

Ready to Elevate Your Dental Lab's Capabilities?

Choosing the right dental furnace is critical for producing strong, precise, and aesthetically perfect restorations. Whether you specialize in zirconia sintering, ceramic pressing, or multi-material workflows, KINTEK has the precision equipment your laboratory needs.

We specialize in providing reliable, high-performance lab equipment and consumables tailored to the demands of modern dental laboratories. Our experts can help you select the perfect furnace to match your materials and workflow, ensuring consistent, high-quality results for your clients.

Contact KINTEK today for a personalized consultation and discover how our dental furnaces can become the foundation of your success.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of corundum tubes in oxygen permeation testing? Ensure Integrity for Bi-doped Membranes

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- What temperature is alumina activated? Unlock Optimal Porosity for Adsorption

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere