At its core, a high-temperature muffle furnace is a specialized oven used to heat materials to extreme temperatures within a highly controlled and isolated environment. These furnaces are staples in laboratories, research units, and industrial facilities for a wide range of applications, including the heat treatment of metals (like annealing and quenching), the processing of advanced materials (like sintering ceramics), and analytical testing (such as ashing samples to determine their inorganic content).

The defining feature of a muffle furnace is not just its high heat, but its method of isolated heating. A protective barrier, or "muffle," separates the material being heated from the heating elements, preventing contamination and ensuring process purity and consistency.

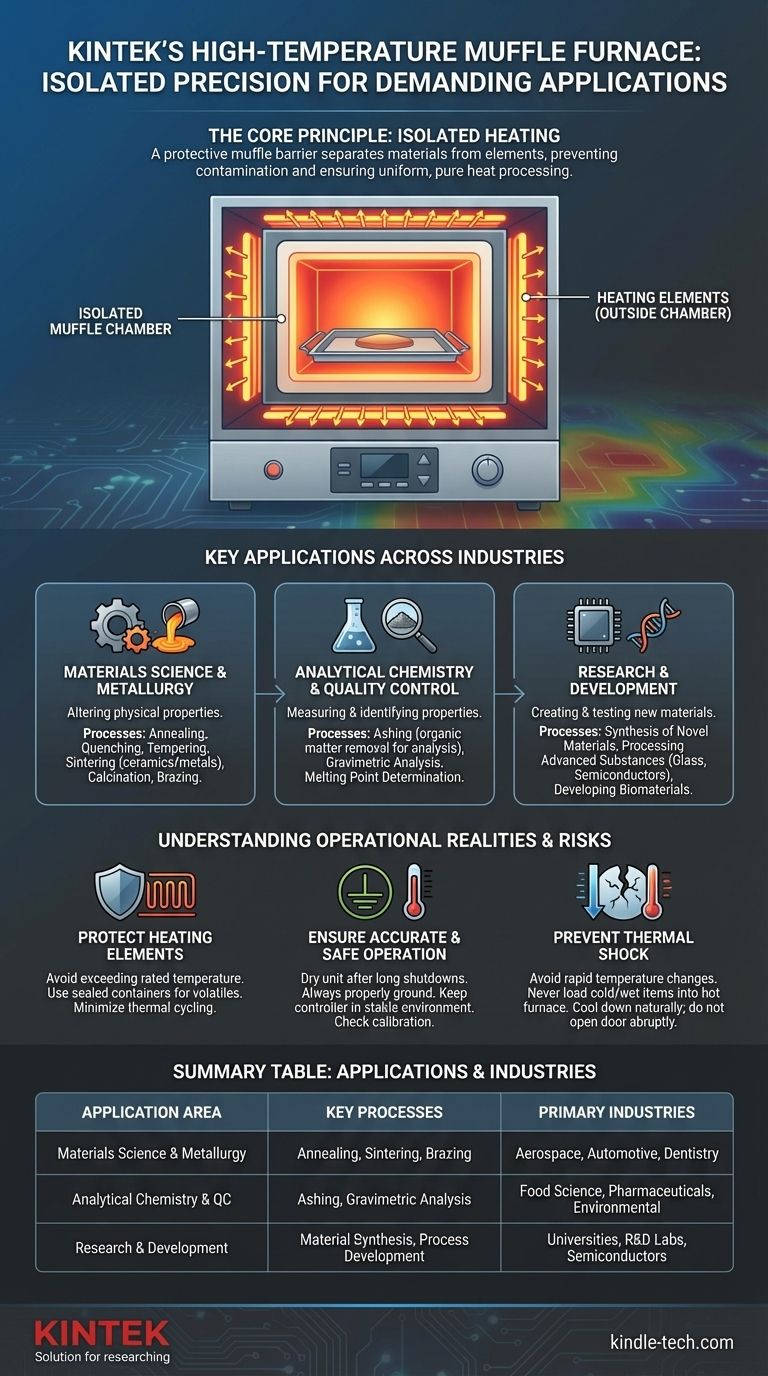

The Core Principle: Isolated High-Temperature Processing

To truly understand the furnace's applications, you must first understand its fundamental design principle. The "muffle" is the key.

What "Muffle" Means

The term "muffle" refers to the insulated inner chamber of the furnace that holds the sample. This chamber is typically made from a high-temperature ceramic material.

The heating elements are positioned on the outside of this muffle. This means heat is transferred to your sample through radiation and convection, but the elements never make direct contact with the sample or its immediate atmosphere.

Preventing Contamination

This separation is the furnace's most critical advantage. It prevents contaminants from the heating elements (such as flaking oxides) or byproducts of fuel combustion (in gas-fired models) from corrupting the sample.

This purity is non-negotiable in applications like analytical chemistry, where trace contaminants would invalidate results, or in the manufacturing of sensitive electronics and biomaterials.

Ensuring Uniform Heat

The enclosed design of the muffle promotes a stable and uniform thermal environment. It ensures the entire sample is heated evenly, which is vital for achieving consistent material properties during processes like annealing steel or sintering a ceramic part.

Key Applications Across Industries

A muffle furnace's ability to provide pure, uniform heat makes it indispensable across numerous fields. Its applications can be grouped into three main categories.

Materials Science and Metallurgy

This is a primary use case, focusing on altering the physical properties of materials.

Common processes include heat-treating metals (annealing, quenching, tempering), sintering (fusing powdered materials like ceramics or metals into a solid mass), calcination (heating solids to drive off volatile substances), and brazing components. Industries from aerospace to dentistry rely on these capabilities.

Analytical Chemistry and Quality Control

In analytical settings, the goal is to measure and identify a material's properties.

The most common application is ashing, where a sample is burned at high temperatures to remove all organic matter. This allows technicians to accurately weigh the remaining non-combustible ash, a standard procedure in food science, water quality analysis, and materials testing. Other uses include drug inspections and determining the melting point of ash.

Research and Development

For researchers, the muffle furnace is a versatile tool for creating and testing new materials.

It is used for the synthesis of novel materials, processing advanced substances like glass and semiconductors, and developing new biomaterials. Its controlled environment allows for repeatable experiments that are crucial for advancing material science.

Understanding the Operational Realities and Risks

While powerful, a muffle furnace is a sensitive piece of equipment that requires careful operation to ensure safety, accuracy, and longevity. Ignoring these realities can lead to damaged equipment, ruined samples, and inaccurate results.

Protecting the Heating Elements

The heating elements are the heart of the furnace and its most fragile component. They are often protected by a thin oxide layer that can be easily damaged.

You must avoid exceeding the furnace's rated temperature. When heating volatile materials, they must be placed in a sealed container to prevent vapors from attacking the elements. Finally, frequent shutdowns should be minimized, as thermal cycling can stress and degrade the elements over time.

Ensuring Accurate and Safe Operation

Procedural discipline is essential. The furnace must be dried at a low temperature (e.g., 200°C) after a long shutdown to prevent moisture from causing damage upon rapid heating.

For safety, the unit must always be properly grounded. For accuracy, the temperature controller must be kept in a stable environment (typically 0°C-40°C) and its calibration should be checked regularly.

Preventing Thermal Shock

Rapid temperature changes can crack the furnace's ceramic muffle or the material being processed. Never place a cold, wet item into a hot furnace.

Likewise, allow the furnace and its contents to cool down naturally after the process is complete. Abruptly opening the door to cool the chamber can cause irreparable damage from thermal shock.

Making the Right Choice for Your Goal

To apply this knowledge, match your primary objective to the furnace's core capabilities.

- If your primary focus is analytical testing: Use the furnace for precise ashing, gravimetric analysis, or determining the chemical properties of materials at high temperatures.

- If your primary focus is materials manufacturing or metallurgy: Leverage its capabilities for heat treating metals, sintering ceramics, or brazing components where consistency and purity are paramount.

- If your primary focus is research and development: The furnace is an essential tool for synthesizing new materials and conducting repeatable high-temperature experiments in a contamination-free environment.

Understanding that a muffle furnace provides isolated, uniform heat is the key to unlocking its full potential for precise and reliable results.

Summary Table:

| Application Area | Key Processes | Primary Industries |

|---|---|---|

| Materials Science & Metallurgy | Annealing, Sintering, Brazing | Aerospace, Automotive, Dentistry |

| Analytical Chemistry & QC | Ashing, Gravimetric Analysis | Food Science, Pharmaceuticals, Environmental |

| Research & Development | Material Synthesis, Process Development | Universities, R&D Labs, Semiconductors |

Need precise, contamination-free high-temperature processing? KINTEK specializes in high-quality lab equipment, including muffle furnaces designed for the demanding needs of laboratories and industrial facilities. Our solutions ensure the reliability and purity required for your critical applications in materials science, analytical testing, and R&D. Contact our experts today to find the perfect furnace for your goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What role does a high-temperature box furnace play in the production of iron-substituted manganese oxide powders?

- What is the heating element of a muffle furnace? The Engine for High-Temp Precision

- Why is a high-temperature muffle furnace critical for the impregnation method of rare earth catalyst production?

- How does a muffle furnace facilitate ZrW2O8 powder synthesis? Optimize Negative Thermal Expansion (NTE) Material Quality

- What function does a muffle furnace serve in RPPO solid electrolyte synthesis? Precision Heat for Advanced Materials

- What is the cooling rate for a muffle furnace? Achieve Optimal Cooling for Your Lab Processes

- What do you know about heat treatment furnace? Master Material Transformation with Precision Control

- What Role Do High-Temperature Furnaces Play in 304L Sensitization? Achieve Precise Thermal Control for Material Research