At its core, a high-temperature vacuum sintering furnace is a highly specialized piece of industrial equipment that heats materials to extreme temperatures within a controlled, airless environment. Its primary function is to bond, compact, and strengthen a material by heating it to a point just below its melting point, a process known as sintering. The critical feature is the vacuum, which eliminates atmospheric gases to prevent contamination and unwanted chemical reactions during this intense heating process.

The true value of a vacuum furnace isn't just the extreme heat it can generate; it's the pristine, controlled environment it creates. By removing reactive gases like oxygen and nitrogen, it enables the production of materials with superior density, purity, and strength that would be impossible to achieve in a conventional furnace.

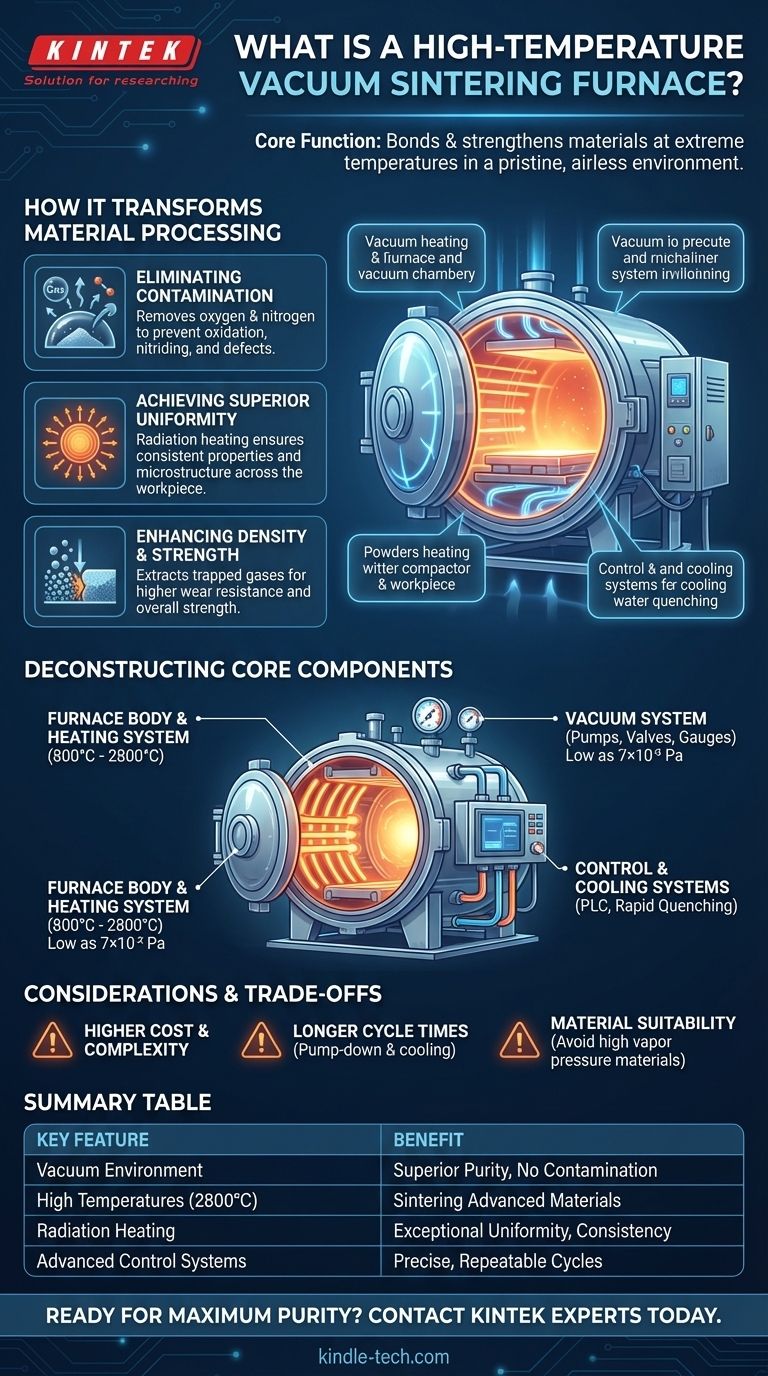

How a Vacuum Furnace Transforms Material Processing

A vacuum furnace isn't simply a hotter oven; it operates on fundamentally different principles. The absence of air allows for unique physical and chemical interactions that are critical for developing advanced materials.

The Role of the Vacuum: Eliminating Contamination

The primary purpose of the vacuum is to create a chemically inert environment. By pumping out atmospheric gases, the system prevents harmful substances like oxygen, nitrogen, and water vapor from reacting with the hot material.

This eliminates unwanted processes like oxidation, nitriding, and decarburization, which can cause defects and degrade the final product's quality. It also helps remove the thin oxide film present on most materials, improving wettability and bonding between particles.

Achieving Superior Temperature Uniformity

In a conventional furnace, air creates convection currents that can lead to uneven heating and hot spots. In a vacuum, heat transfer occurs primarily through radiation, resulting in exceptionally uniform heating across the entire workpiece.

This uniformity is essential for producing high-quality materials with consistent properties and microstructure from edge to core.

Enhancing Material Density and Strength

During the sintering of powdered materials, gases can become trapped within the pores of the compact. The vacuum environment helps extract these trapped gases before the pores close.

This process significantly improves the final density of the material, leading to enhanced mechanical properties such as higher wear resistance and greater overall strength.

Deconstructing the Core Components

A high-temperature vacuum sintering furnace is a complex system where several key components work in unison to achieve precise, repeatable results.

The Furnace Body and Heating System

This is the main chamber that contains the workpiece and the heating elements. The furnace is designed to withstand both extreme temperatures—often reaching 800 °C to 2800 °C—and the immense pressures of a deep vacuum.

The Vacuum System: The Heart of the Operation

The vacuum system is responsible for removing air from the furnace chamber. It typically consists of a series of pumps (such as mechanical, Roots, and diffusion pumps), along with valves and gauges to control and monitor the vacuum level.

This system can achieve vacuum levels as low as 7×10⁻³ Pa or even lower, depending on the process requirements.

The Control and Cooling Systems

Modern furnaces rely on sophisticated control systems. A PLC (Programmable Logic Controller) automates and monitors water, electricity, and vacuum systems for safety and repeatability.

An intelligent temperature controller ensures precise heating cycles, while an internal pure water cooling system allows for rapid cooling (quenching) to lock in desired material properties and shorten process times.

Understanding the Trade-offs and Considerations

While powerful, vacuum furnaces are not a universal solution. Their benefits come with specific operational considerations that are crucial to understand.

Higher Initial Cost and Complexity

These are highly engineered, expensive pieces of equipment. The complexity of the vacuum pumps, control systems, and high-temperature-rated materials requires significant capital investment and specialized maintenance.

Longer Process Cycle Times

Achieving a deep vacuum, a process known as "pump-down," takes time. This, combined with controlled heating and cooling cycles, often results in longer overall process times compared to atmospheric furnaces.

Material Suitability

Certain materials with high vapor pressures (materials that evaporate easily) are not suitable for vacuum processing. At high temperatures and low pressures, these materials can "outgas," contaminating the furnace and altering the material's composition.

Making the Right Choice for Your Goal

Selecting the right thermal processing technology depends entirely on the desired qualities of your final product.

- If your primary focus is maximum material purity and density: A vacuum furnace is essential for eliminating atmospheric contamination and achieving near-theoretical material density.

- If you are processing oxygen-sensitive materials (like titanium or refractory metals): The inert vacuum environment is non-negotiable to prevent the formation of brittle oxides.

- If your application requires precise, repeatable heat treatment cycles: The advanced computer controls of a vacuum furnace offer unparalleled consistency from batch to batch.

Ultimately, choosing a vacuum sintering furnace is a strategic decision to prioritize material integrity and absolute process control.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Vacuum Environment | Eliminates contamination (oxidation, nitriding) for superior purity. |

| High Temperatures (up to 2800°C) | Enables sintering of advanced materials like metals and ceramics. |

| Radiation Heating | Provides exceptional temperature uniformity for consistent results. |

| Advanced Control Systems | Ensures precise, repeatable, and automated processing cycles. |

Ready to achieve maximum purity and strength in your materials?

KINTEK specializes in high-performance lab equipment, including vacuum sintering furnaces designed for demanding laboratory and R&D applications. Our solutions provide the precise control and contamination-free environment you need to develop superior materials.

Contact our experts today to discuss how a KINTEK vacuum furnace can advance your research and production goals.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- What kind of furnace is used for casting? Choose the Right Heating Technology for Your Metal

- What is the temperature of vacuum casting? Mastering the Thermal Profile for Flawless Parts

- What are the main components of a hot zone used in a high-temperature furnace? Ensure Optimal Performance and Efficiency

- What is the purpose of vacuum heating equipment in HT-Na₃PS₄ preparation? Optimize Your Electrolyte Conductivity

- What hazard is involved when using a furnace? Protect Your Home from the Silent Killer

- What is the traditional sintering process? A Guide to Powder Metallurgy & Ceramic Fabrication