The single most critical factor when purchasing a dental furnace is its material compatibility. You must ensure the furnace is fully capable of processing the specific ceramics, zirconia, or other materials your practice or lab plans to use, as this capability dictates every other important feature.

Your choice of dental materials should dictate your furnace selection, not the other way around. Investing in a furnace without a clear materials strategy leads to limited capabilities, compromised restoration quality, and a poor return on investment.

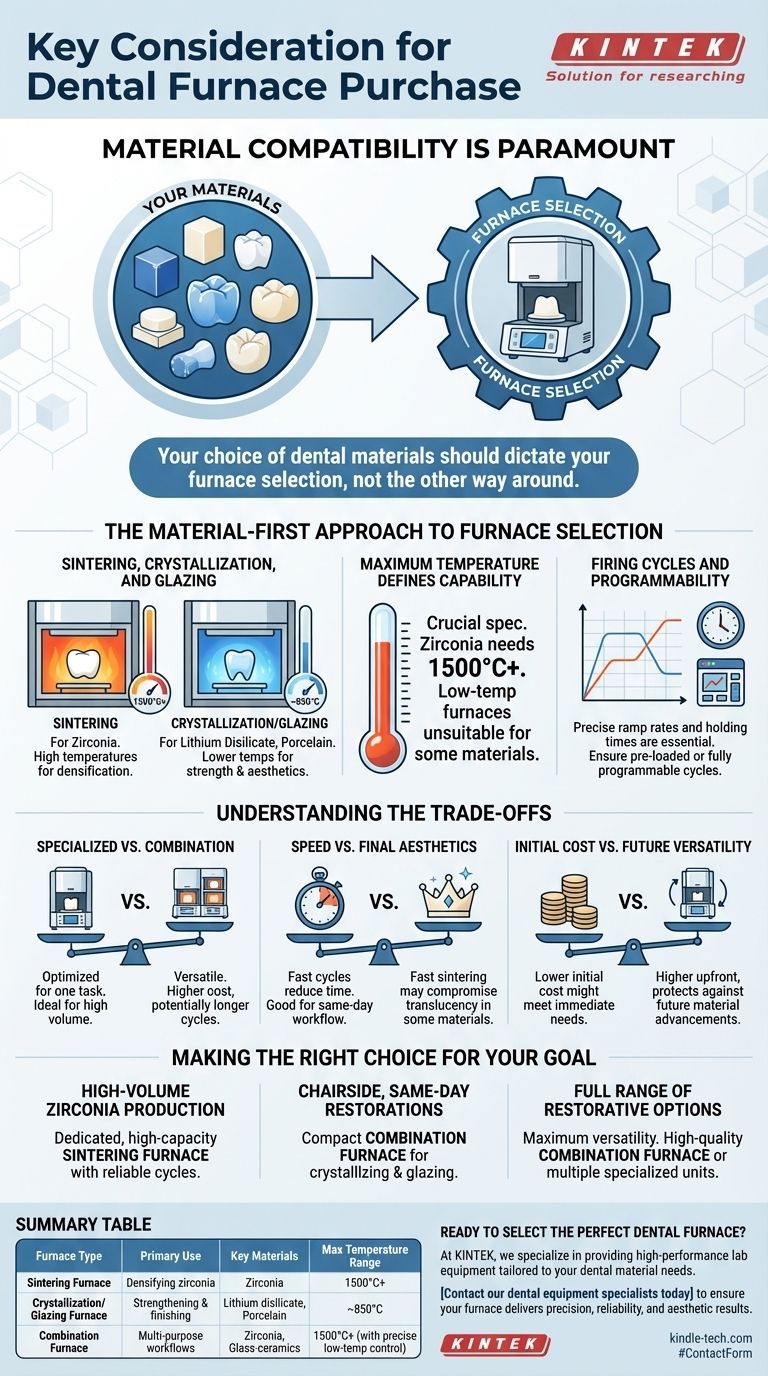

The Material-First Approach to Furnace Selection

The type of dental restoration you create determines the material you use, and that material has very specific processing requirements. A furnace is not a one-size-fits-all device; it is a highly specialized tool designed for precise thermal processes.

Sintering, Crystallization, and Glazing

Different materials require different heat treatments. A sintering furnace is designed for zirconia, reaching very high temperatures (often 1500°C or more) to transform the milled "green state" material into its final, dense, and strong form.

In contrast, porcelain or crystallization furnaces operate at lower temperatures. They are used for materials like glass-ceramics (e.g., lithium disilicate) to run crystallization and glazing cycles, which give the restoration its final strength and aesthetic finish.

Maximum Temperature Defines Capability

The single biggest technical specification dictated by materials is the furnace's maximum temperature. If you plan to work with zirconia, a furnace that only reaches 1100°C is entirely unsuitable.

Conversely, a high-temperature sintering furnace may be overkill or lack the nuanced control needed for delicate porcelain work, although many modern "combination" furnaces aim to solve this.

Firing Cycles and Programmability

Beyond just temperature, different materials require specific heating and cooling rates, known as the "ramp rate," and holding times. A furnace must be able to execute these programs precisely.

Ensure the furnace has either pre-loaded programs for your preferred materials or is fully programmable to allow you to create custom cycles for new materials you may adopt in the future.

Understanding the Trade-offs

Choosing a furnace involves balancing capabilities, cost, and workflow efficiency. Understanding the inherent trade-offs is key to making a wise decision.

Specialized vs. Combination Furnaces

A specialized furnace (e.g., sintering-only) is optimized for one task and often performs it exceptionally well. This is ideal for labs with high volumes of a single material type.

A combination furnace offers versatility, capable of handling both high-temperature sintering and lower-temperature glazing. The trade-off may be a higher initial cost and potentially longer cycle times when switching between functions.

Speed vs. Final Aesthetics

Many modern furnaces offer "speed" or "fast" firing cycles, which can dramatically reduce processing time. This is a significant workflow advantage for same-day dentistry.

However, for some materials, particularly zirconia, fast sintering can sometimes negatively impact the final translucency and aesthetic outcome. You must weigh the need for speed against the demand for the highest quality aesthetics.

Initial Cost vs. Future Versatility

It can be tempting to purchase a less expensive furnace that only meets your immediate needs. This can be a costly mistake.

Investing in a more versatile and programmable furnace, while more expensive upfront, protects your practice or lab from being unable to adopt newer, more advanced materials as they come to market.

Making the Right Choice for Your Goal

Your decision should be rooted in your primary business objective.

- If your primary focus is high-volume zirconia production: You need a dedicated, high-capacity sintering furnace with reliable and potentially fast-sintering cycles.

- If your primary focus is chairside, same-day restorations: A compact combination furnace designed for crystallizing and glazing glass-ceramics is your most critical asset.

- If your primary focus is offering a full range of restorative options: You require maximum versatility, which may mean investing in a high-quality combination furnace or multiple specialized units.

Choosing the right furnace begins with a clear vision of the materials you will use today and tomorrow.

Summary Table:

| Furnace Type | Primary Use | Key Materials | Max Temperature Range |

|---|---|---|---|

| Sintering Furnace | Densifying zirconia | Zirconia | 1500°C+ |

| Crystallization/Glazing Furnace | Strengthening & finishing | Lithium disilicate, Porcelain | ~850°C |

| Combination Furnace | Multi-purpose workflows | Zirconia, Glass-ceramics | 1500°C+ (with precise low-temp control) |

Ready to select the perfect dental furnace for your practice or lab?

At KINTEK, we specialize in providing high-performance lab equipment tailored to your specific dental material needs. Whether you require a dedicated sintering furnace for high-volume zirconia or a versatile combination unit for a full range of restorations, our experts will help you make a future-proof investment.

Contact our dental equipment specialists today for a personalized consultation and ensure your furnace delivers the precision, reliability, and aesthetic results your patients deserve.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is a dental burnout furnace? A Precision Tool for Flawless Dental Restorations

- What is sintering dental materials? The Key to Durable, High-Strength Dental Restorations

- What are the characteristics of dental ceramics? Achieve Superior Esthetics and Durability

- What is the difference between dental ceramic and dental porcelain? Choosing the Right Material for Your Restoration

- What is the difference between zirconia and ceramic? A Guide to Choosing the Right Dental Crown

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the major drawback of all-ceramic restorations in the posterior of the mouth? Overcoming Fracture Risk for Long-Lasting Results

- What is the main disadvantage of zirconia? Balancing Strength, Aesthetics, and Tooth Wear