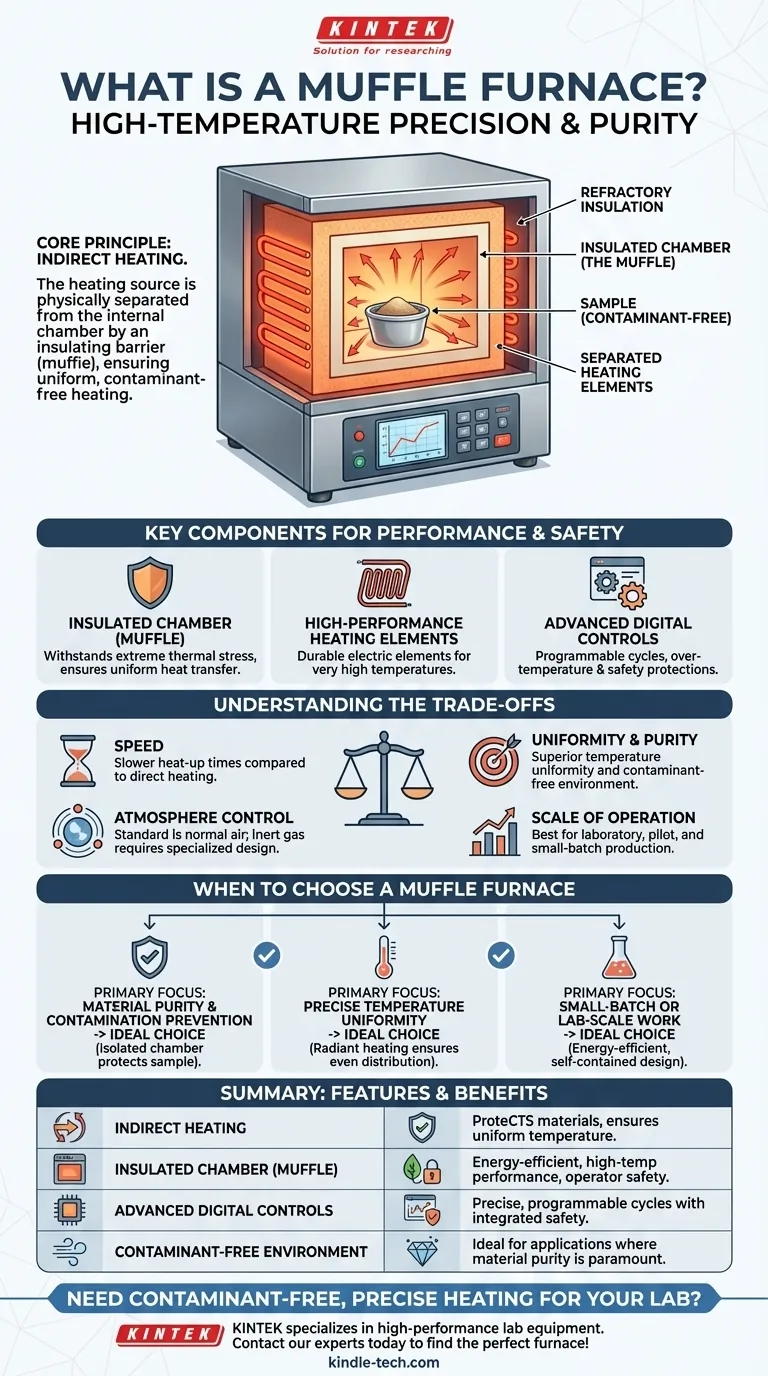

At its core, a muffle furnace is a high-temperature oven defined by a critical design feature: the heating source is physically separated from the internal heating chamber. This separation is achieved by an insulating barrier, or "muffle," which ensures the material being heated is protected from direct contact with the heating elements and any potential contaminants.

The essential purpose of a muffle furnace is not just to get hot, but to provide an exceptionally uniform and contaminant-free heating environment. This makes it indispensable for processes where material purity and precise temperature control are paramount.

How a Muffle Furnace Achieves Precise Heating

A muffle furnace's unique value comes from its method of indirect heating. Understanding this principle is key to knowing why it's chosen for sensitive applications.

The Principle of Indirect Heat

Instead of exposing a material directly to heating elements, the furnace heats the walls of the internal chamber (the muffle).

This chamber, typically made of high-performance ceramic or metallic alloys, then radiates heat evenly from all sides onto the workpiece inside. This method eliminates hot spots and ensures a homogenous temperature distribution.

The Role of Refractory Materials

The entire chamber is encased in highly effective insulating materials, often refractory bricks or ceramic fiber.

This robust insulation serves two purposes: it prevents heat loss, making the furnace energy-efficient and capable of rapid heating, and it protects the outer shell and the operator from the extreme internal temperatures.

Preventing Contamination

The separation between the heating elements and the chamber is fundamental.

In older fuel-fired models, this design kept byproducts of combustion from contaminating the sample. In modern electric furnaces, it prevents materials from flaking off the heating elements onto the sample, or vice versa, ensuring the purity of the final product.

Key Components of a Modern Furnace

While the principle is straightforward, modern muffle furnaces incorporate advanced components for safety, control, and performance.

The Insulated Chamber (The Muffle)

This is the heart of the furnace, constructed from materials that can withstand extreme thermal stress while providing uniform heat transfer.

High-Performance Heating Elements

Modern furnaces use durable electric heating elements capable of reaching very high temperatures. Common types include high-resistance wires, silicon carbon rods, and silicon-molybdenum rods.

Advanced Digital Controls

The brain of the furnace is its control system. Modern units feature multi-segment programmable controllers that allow users to execute precise heating and cooling cycles automatically.

They also integrate critical safety features like over-temperature protection, which shuts the furnace down if it exceeds a set limit, along with over-current and leakage protection.

Understanding the Trade-offs

No single tool is perfect for every job. A muffle furnace offers precision at the cost of other factors.

Speed vs. Uniformity

The indirect heating method that guarantees temperature uniformity can sometimes result in slightly slower heat-up times compared to furnaces where the sample is exposed directly to the heat source.

Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere. While some specialized models allow for the introduction of inert gases to prevent oxidation, this is not an inherent feature and requires a more complex and costly design.

Scale of Operation

Muffle furnaces are typically designed for laboratory work, pilot projects, and small-batch production. Their design is less suited for large-scale, continuous industrial processes where throughput is the primary concern.

How to Apply This to Your Goal

Choosing the right heating equipment depends entirely on your desired outcome.

- If your primary focus is material purity and preventing contamination: A muffle furnace is ideal because its isolated chamber protects your sample from the heating elements.

- If your primary focus is precise temperature uniformity: The indirect, radiant heating design ensures even heat distribution, which is critical for sensitive heat-treating and materials testing.

- If your primary focus is small-batch or laboratory-scale work: The self-contained, energy-efficient cabinet design is perfectly suited for research, development, and quality control applications.

Ultimately, a muffle furnace is the definitive tool when the integrity of the material and the precision of the process cannot be compromised.

Summary Table:

| Feature | Benefit |

|---|---|

| Indirect Heating | Protects materials from contamination, ensures uniform temperature distribution. |

| Insulated Chamber (Muffle) | Provides energy-efficient, high-temperature performance and operator safety. |

| Advanced Digital Controls | Enables precise, programmable heating cycles with integrated safety protections. |

| Contaminant-Free Environment | Ideal for applications where material purity is paramount. |

Need contaminant-free, precise heating for your lab?

KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for material purity and precise temperature control. Whether you're in research, quality control, or small-batch production, our solutions ensure your processes are reliable and your results are uncompromised.

Contact our experts today to find the perfect furnace for your specific application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the working principles of furnace? A Guide to Combustion, Resistance, and Induction Heating

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing

- What is the maintenance of laboratory equipment? Ensure Data Integrity and Extend Equipment Lifespan

- What is the maximum temperature of muffle furnace? A Guide from 1100°C to 1800°C

- What is the heating mechanism of a muffle furnace? Achieve Clean, Uniform High-Temperature Processing