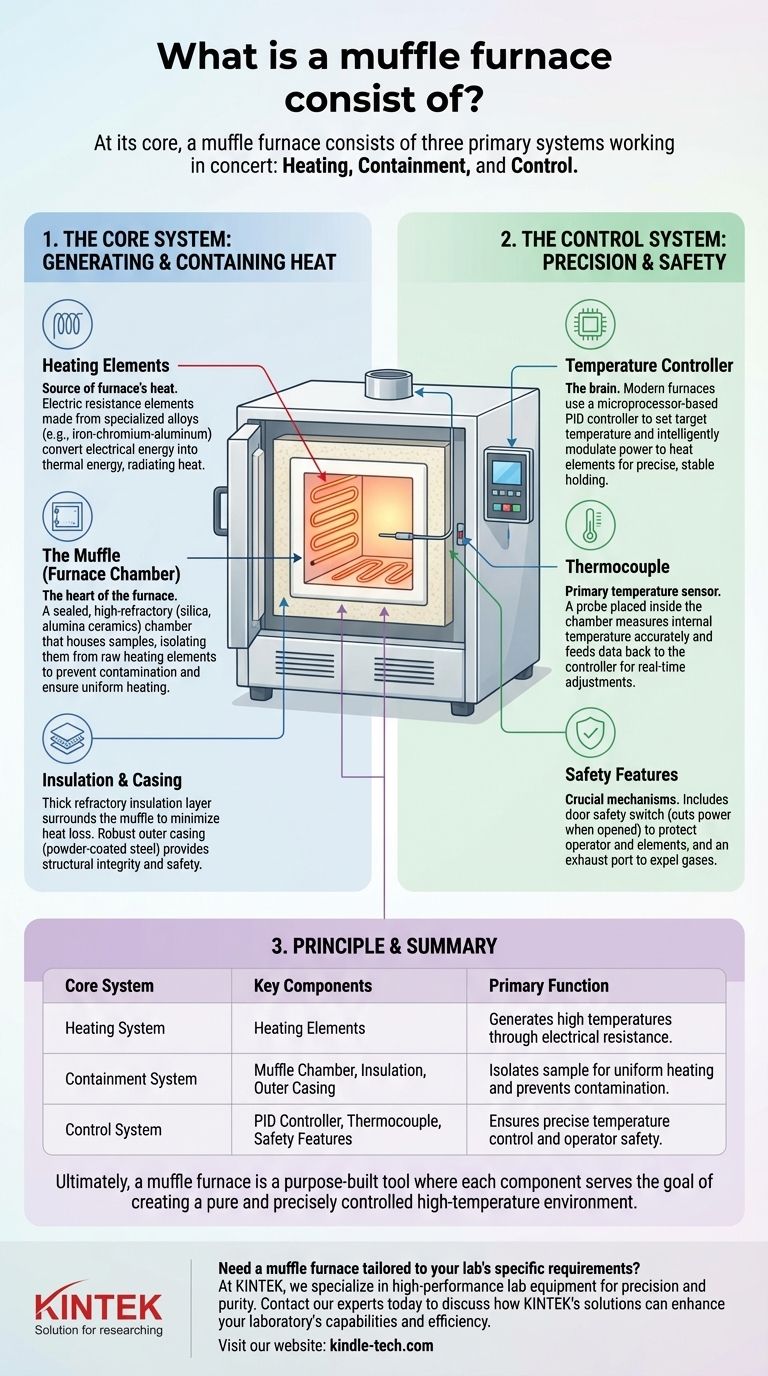

At its core, a muffle furnace consists of three primary systems working in concert. These are the heating system (heating elements), the containment system (an insulated chamber called a muffle), and the control system (a temperature controller and sensor). Together, these components create a highly controlled, high-temperature environment that isolates a sample from direct contact with the heating source.

A muffle furnace is fundamentally an insulated box designed for high-temperature applications. Its defining feature is the "muffle"—an inner chamber that separates the material being heated from the heating elements, ensuring uniform heat and preventing contamination from combustion byproducts.

The Core System: Generating and Containing Heat

The primary function of a furnace is to generate and maintain extreme heat. This is accomplished by the interplay of the heating elements, the inner chamber, and the insulation.

Heating Elements

The heating elements are the source of the furnace's heat. They are typically electric resistance elements made from specialized alloys, such as iron-chromium-aluminum, that can withstand repeated, rapid temperature changes without degrading.

These elements convert electrical energy directly into thermal energy, radiating heat throughout the inner chamber.

The Muffle (Furnace Chamber)

The muffle, or inner chamber, is the heart of the furnace. It is a sealed chamber made from high-refractory materials like silica and alumina ceramics.

Its critical purpose is to house the samples and isolate them from the raw heating elements. This separation prevents contamination and ensures heat is transferred uniformly through radiation and convection.

Insulation and Casing

Surrounding the muffle is a thick layer of insulation. This refractory material is essential for reaching high temperatures efficiently and maintaining them with stability.

The insulation minimizes heat loss to the surrounding environment. The entire assembly is protected by a robust outer casing, often made of powder-coated steel, which provides structural integrity and operator safety.

The Control System: Precision and Safety

Achieving and holding a precise temperature is critical for scientific and industrial processes. The control system is responsible for this regulation and for ensuring safe operation.

Temperature Controller

The temperature controller is the brain of the furnace. Modern furnaces use a microprocessor-based PID (Proportional-Integral-Derivative) controller.

This device allows the user to set a target temperature. It then intelligently modulates the power sent to the heating elements to reach that setpoint quickly and hold it with minimal fluctuation.

Thermocouple

The thermocouple is the furnace's primary temperature sensor. It is a probe placed inside the chamber that measures the internal temperature with high accuracy.

It constantly feeds this temperature reading back to the controller, which uses the data to make real-time adjustments to the power output.

Safety Features

Modern furnaces include crucial safety mechanisms. A door safety switch is a common feature that automatically cuts power to the heating elements when the door is opened.

This protects the operator from electric shock and prevents thermal shock to the heating elements. An exhaust port or vent is also often included to safely expel any gases or fumes produced during the heating process.

The Principle of the Muffle: Advantages and Implications

The defining characteristic of this furnace type—the muffle—is not just a box. It's a design choice with specific trade-offs that make it ideal for certain applications.

The Advantage: Purity and Uniformity

The primary benefit of the muffle design is isolation. By separating the workload from the heating elements and any potential byproducts of combustion (in fuel-fired models), it ensures a clean heating environment.

This is critical for processes like ashing, material analysis, or heat-treating sensitive alloys where contamination would ruin the result. The design also promotes more uniform heating through radiation from the chamber walls.

The Implication: Heat Transfer

Because the heat is not applied directly to the sample, the heat transfer is indirect. This can mean slightly slower heating cycles compared to a direct-radiation oven.

However, for most applications requiring a muffle furnace, the benefits of a pure, controlled, and uniform atmosphere far outweigh any minor difference in heating speed.

Making the Right Choice for Your Application

Understanding these components helps you evaluate a furnace's capabilities based on its specifications.

- If your primary focus is material purity: Pay close attention to the muffle chamber's material composition to ensure it is inert and suitable for your samples.

- If your primary focus is temperature accuracy: Verify that the furnace uses a high-quality PID controller and a suitable thermocouple type for your required temperature range.

- If your primary focus is safety and venting: Ensure the model includes essential features like a door safety switch and an exhaust port, especially if you are working with materials that produce fumes.

Ultimately, a muffle furnace is a purpose-built tool where each component serves the goal of creating a pure and precisely controlled high-temperature environment.

Summary Table:

| Core System | Key Components | Primary Function |

|---|---|---|

| Heating System | Heating Elements (e.g., iron-chromium-aluminum alloys) | Generates high temperatures through electrical resistance |

| Containment System | Muffle Chamber (ceramic), Insulation, Outer Casing | Isolates sample for uniform heating and prevents contamination |

| Control System | PID Controller, Thermocouple, Safety Features (door switch, exhaust) | Ensures precise temperature control and operator safety |

Need a muffle furnace tailored to your lab's specific requirements?

At KINTEK, we specialize in high-performance lab equipment designed for precision and purity. Whether your priority is material purity, temperature accuracy, or operational safety, our range of muffle furnaces delivers reliable, contamination-free results for applications like ashing, heat treatment, and material analysis.

Contact our experts today to discuss how KINTEK's solutions can enhance your laboratory's capabilities and efficiency.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the minimum temperature for a muffle furnace? Understanding Its High-Tech Design

- What is a muffle furnace used to determine? Measure Ash, Volatile Matter & Moisture Precisely

- What is ramp rate and how does that affect a melting point measurement? Master the Key to Accurate Thermal Analysis

- How do you check the ash content of a muffle furnace? A Step-by-Step Guide to Material Analysis

- What affects melting range? Understand the Critical Role of Purity and Structure