In metallurgy, a muffle furnace is a high-precision oven used for a wide range of thermal processes. It is primarily used for heat-treating metal alloys through methods like annealing, tempering, and sintering, as well as for analytical preparations such as drying precipitates and conducting casting or flammability tests. Its value lies in creating a controlled, high-temperature environment.

The core function of a muffle furnace isn't just to generate heat, but to do so in a clean, isolated chamber. This separation protects the metallurgical sample from contamination by fuel or heating elements, ensuring the integrity of the process and the purity of the final material.

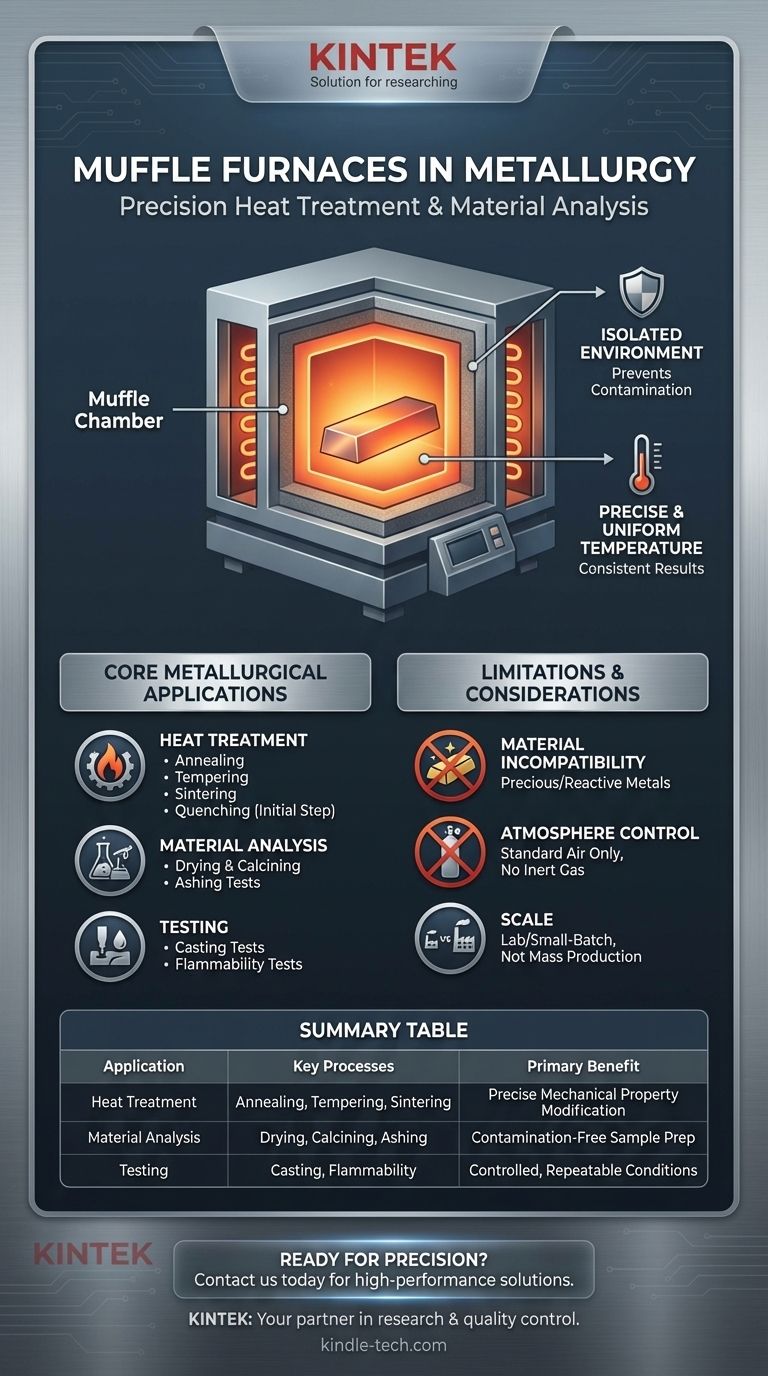

The Role of a Muffle Furnace in Metallurgy

A muffle furnace's design is central to its purpose. The term "muffle" refers to the insulated inner chamber that separates the material being heated from the actual heating elements. This design delivers two critical advantages for metallurgical work.

Isolating the Material from Contamination

The primary benefit is creating an uncontaminated environment. In direct-fired furnaces, byproducts of combustion can react with the metal's surface, causing unwanted oxidation or chemical changes. A muffle furnace completely prevents this interaction.

This isolation is essential for processes where surface finish and material purity are critical.

Achieving Precise and Uniform Temperature

Metallurgical heat treatments demand accuracy. The final properties of a metal—its hardness, toughness, or ductility—are often determined by holding it at a specific temperature for an exact duration.

Muffle furnaces are engineered for exceptional temperature stability and uniformity, ensuring that the entire part or sample receives the same thermal treatment for consistent, predictable results.

Core Metallurgical Applications

The combination of a clean environment and precise temperature control makes the muffle furnace a versatile tool for several key applications.

Heat Treatment Processes

Heat treatment modifies a metal's microstructure to achieve desired mechanical properties.

- Annealing: Heating and slowly cooling a metal to soften it, improve its ductility, and make it easier to work with.

- Tempering: Heating a previously hardened metal to a lower temperature to decrease its brittleness and increase its toughness.

- Quenching: The controlled, rapid cooling phase after heating, often done outside the furnace, but the initial heating step requires the furnace's precision.

- Sintering: Fusing powdered metals into a solid mass by applying heat below the material's melting point.

Material Analysis and Preparation

The furnace is also a staple in metallurgical labs for preparing and testing materials.

- Drying and Calcining: Removing moisture or volatile compounds from precipitates or ore samples at high temperatures before chemical analysis.

- Casting Tests: Melting small batches of metal under controlled conditions to test for casting properties or to create samples for analysis.

- Flammability and Ashing Tests: Determining the composition or combustion resistance of a material by heating it to a specific temperature and measuring the results.

Understanding the Trade-offs and Limitations

While versatile, a muffle furnace is not universally applicable. Understanding its limitations is key to using it correctly.

Material Incompatibility

Certain materials are not suitable for a standard muffle furnace. For example, precious metals like platinum or solid gold often require specialized equipment due to their high value and specific heating requirements, which can be compromised in a general-purpose furnace.

Atmosphere Control

A standard muffle furnace operates with an air atmosphere. This is unsuitable for highly reactive metals that oxidize rapidly when heated, such as titanium or certain specialty steels. These metals require furnaces with controlled inert gas (e.g., argon) or vacuum atmospheres.

Scale and Throughput

Muffle furnaces are typically designed for laboratory-scale work or small-batch industrial production. They are not efficient for large-scale manufacturing, where larger, continuous, or specialized batch furnaces are more appropriate.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the correct tool, consider your primary objective.

- If your primary focus is precise heat treatment for research or small parts: A muffle furnace is the ideal choice for its unparalleled temperature control and clean heating environment.

- If your primary focus is preparing analytical samples: The isolated chamber makes it perfect for drying, calcining, or ashing materials without risk of contamination from heating elements.

- If your primary focus is high-volume production or processing reactive metals: You should investigate larger industrial furnaces or specialized models with atmosphere control systems.

Ultimately, the muffle furnace is the metallurgist's definitive tool for processes where precision, purity, and repeatability are paramount.

Summary Table:

| Application Category | Key Processes | Primary Benefit |

|---|---|---|

| Heat Treatment | Annealing, Tempering, Sintering | Modifies mechanical properties with precision |

| Material Analysis | Drying, Calcining, Ashing Tests | Prepares samples without contamination |

| Testing | Casting Tests, Flammability Tests | Provides controlled, repeatable conditions |

Ready to enhance your metallurgical processes with precision and purity?

KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for accurate heat treatment and contamination-free material analysis. Whether you are annealing, tempering, sintering, or preparing samples, our solutions ensure reliable, repeatable results for your laboratory.

Contact us today to find the perfect furnace for your metallurgical needs and discover how KINTEK can support your research and quality control.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a muffle furnace used for? Achieve Precise High-Temperature Processing in Your Lab

- What is the principle of muffle furnace in lab? Ensuring Sample Purity Through Complete Isolation

- What are the safety precautions for a muffle furnace? A Guide to Preventing Burns, Fires, and Electrical Hazards

- What is the precaution of furnace? Essential Safety Steps to Protect Operators and Equipment

- What are the safety precautions for muffle furnace? A Complete Guide to Safe High-Temperature Operation