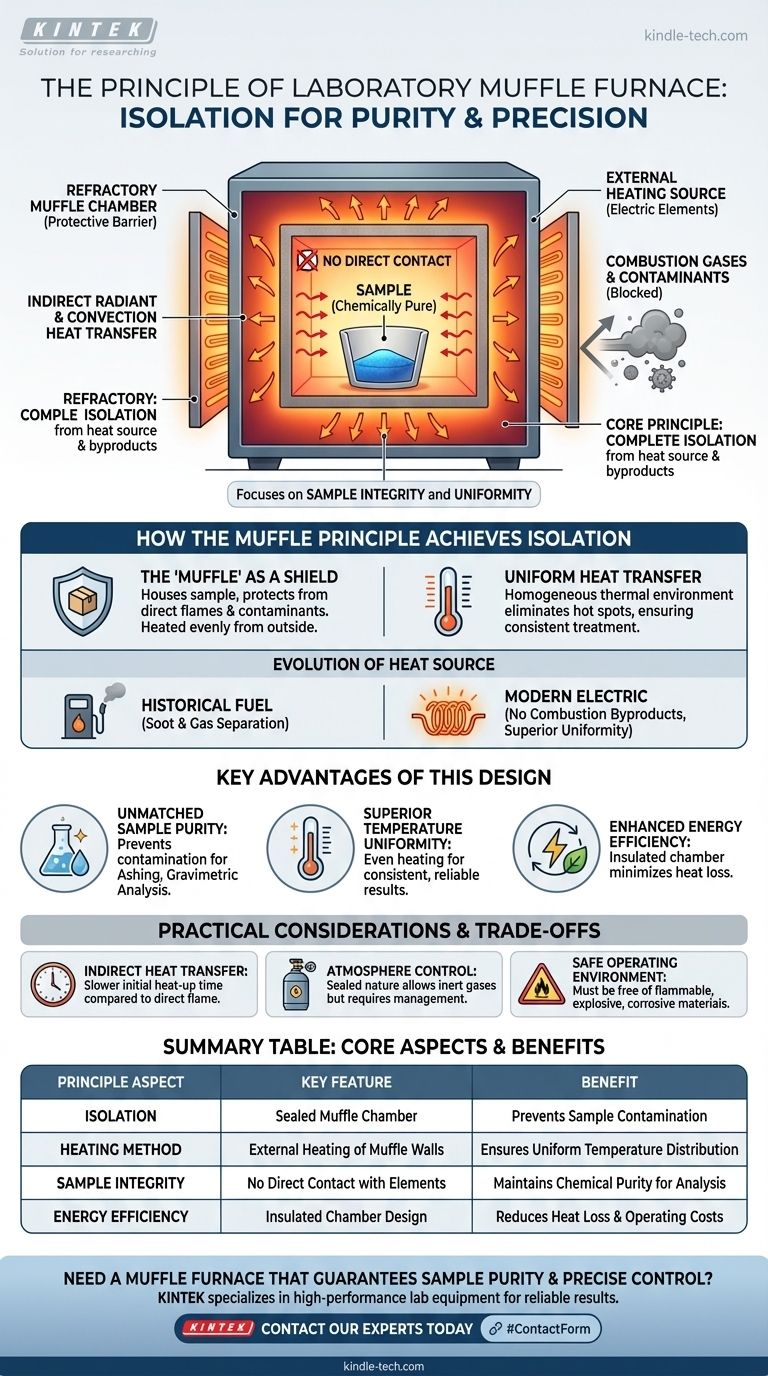

The core principle of a laboratory muffle furnace is the complete isolation of the material being heated from the heat source and its byproducts. This is achieved by enclosing the sample within a separate, sealed chamber (the "muffle") that is heated externally. This design ensures that the sample is never exposed to flames, combustion gases, or contaminants from the heating elements themselves.

The defining feature of a muffle furnace is not simply its ability to reach high temperatures, but its design that guarantees the sample remains chemically pure and is heated with exceptional uniformity. It prioritizes sample integrity above all else.

How the Muffle Principle Achieves Isolation

A muffle furnace’s design is a direct solution to the problem of sample contamination during high-temperature heating. It physically separates the heating process from the material being processed.

The 'Muffle' as a Protective Barrier

The heart of the furnace is the muffle, an inner chamber made from heat-resistant refractory materials. This box acts as a protective shield, housing the sample or workpiece.

The muffle’s walls are heated from the outside, and this heat then radiates and convects throughout the interior. This ensures the sample is heated evenly without direct contact with the energy source.

From Fuel to Electric Elements

Historically, the muffle was essential for separating samples from the soot and corrosive gases of fuel combustion. The heat source (burning gas or coal) would be in a completely independent chamber.

Modern electric muffle furnaces have replaced fuel with high-temperature electric heating elements. While there are no combustion byproducts, the principle of isolation remains critical for preventing any potential contamination from the elements and for ensuring superior temperature uniformity.

Uniform Heat Transfer

By heating the entire exterior of the muffle chamber, the furnace uses a combination of radiant and convection heat transfer. This creates a highly homogeneous thermal environment, eliminating hot spots and ensuring the entire workpiece is treated at the same temperature.

The Key Advantages of This Design

The principle of isolation directly translates into several critical operational advantages in a laboratory or industrial setting.

Unmatched Sample Purity

This is the primary benefit. For applications like ashing, gravimetric analysis, or materials science, preventing any foreign material from contaminating the sample is non-negotiable. The muffle design guarantees this purity.

Superior Temperature Uniformity

Because the sample isn't exposed to a direct flame or a single hot element, the enclosed chamber provides exceptionally even heating. This is crucial for processes where precise temperature control is required for consistent results.

Enhanced Energy Efficiency

The insulated muffle chamber is designed to prevent heat loss. This self-contained structure allows the furnace to reach and maintain high temperatures more efficiently than open-air or direct-heating systems.

Understanding the Practical Considerations

While highly effective, the muffle furnace design comes with specific trade-offs and operational requirements that users must understand.

Indirect Heat Transfer

Heating a sample through the walls of a chamber is an indirect method. Compared to a direct-flame furnace, it can sometimes have a slower initial heat-up time. The trade-off is precision and purity for raw heating speed.

Atmosphere Control

The sealed nature of the muffle chamber means the internal atmosphere is a critical variable. For many advanced processes, this allows for the introduction of inert gases to prevent oxidation, but it also means the default air atmosphere must be considered.

Safe Operating Environment

Like all high-temperature equipment, a muffle furnace requires a safe location. The working area must be free of flammable materials, explosives, and corrosive gases that could compromise the equipment or cause a hazard.

Making the Right Choice for Your Application

The right furnace depends entirely on whether sample integrity or raw heating power is your main priority.

- If your primary focus is analytical purity and precision: A muffle furnace is the correct tool, especially for ashing, heat-treating advanced materials, or chemical analysis.

- If your primary focus is rapid melting or bulk processing where minor contamination is acceptable: A direct-heat furnace, such as a crucible or tube furnace with internal heating, may be more efficient.

Understanding this core principle of isolation empowers you to select the precise tool for achieving reliable and uncontaminated results in your work.

Summary Table:

| Principle Aspect | Key Feature | Benefit |

|---|---|---|

| Isolation | Sealed muffle chamber | Prevents sample contamination from heat source |

| Heating Method | External heating of muffle walls | Ensures uniform temperature distribution |

| Sample Integrity | No direct contact with heating elements | Maintains chemical purity for accurate analysis |

| Energy Efficiency | Insulated chamber design | Reduces heat loss and operating costs |

Need a muffle furnace that guarantees sample purity and precise temperature control? KINTEK specializes in high-performance lab equipment designed for applications like ashing, gravimetric analysis, and materials science. Our muffle furnaces ensure contamination-free heating, uniform temperature distribution, and energy efficiency for reliable results. Contact our experts today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is ash analysis? A Complete Guide to Understanding Inorganic Material Composition

- What is the role of high-temperature muffle furnaces in the synthesis of NASICON-structured LATP ceramic powder?

- How is a muffle furnace applied in assessing the high-temperature oxidation resistance of Ti/Al2O3 composites?

- What is the use of ashing? Isolate and Quantify Total Mineral Content in Your Samples

- What is a muffle furnace and its uses? Achieve Contamination-Free High-Temperature Processing

- Why must LAGP glass melts be immediately placed in a heating furnace for annealing at 500°C after quenching?

- What role does a box muffle furnace play in oxidative roasting? Enhance Your Zinc Sulfide Processing Efficiency

- What is the temperature for sintering? A Guide to Material-Specific Ranges and Trade-offs