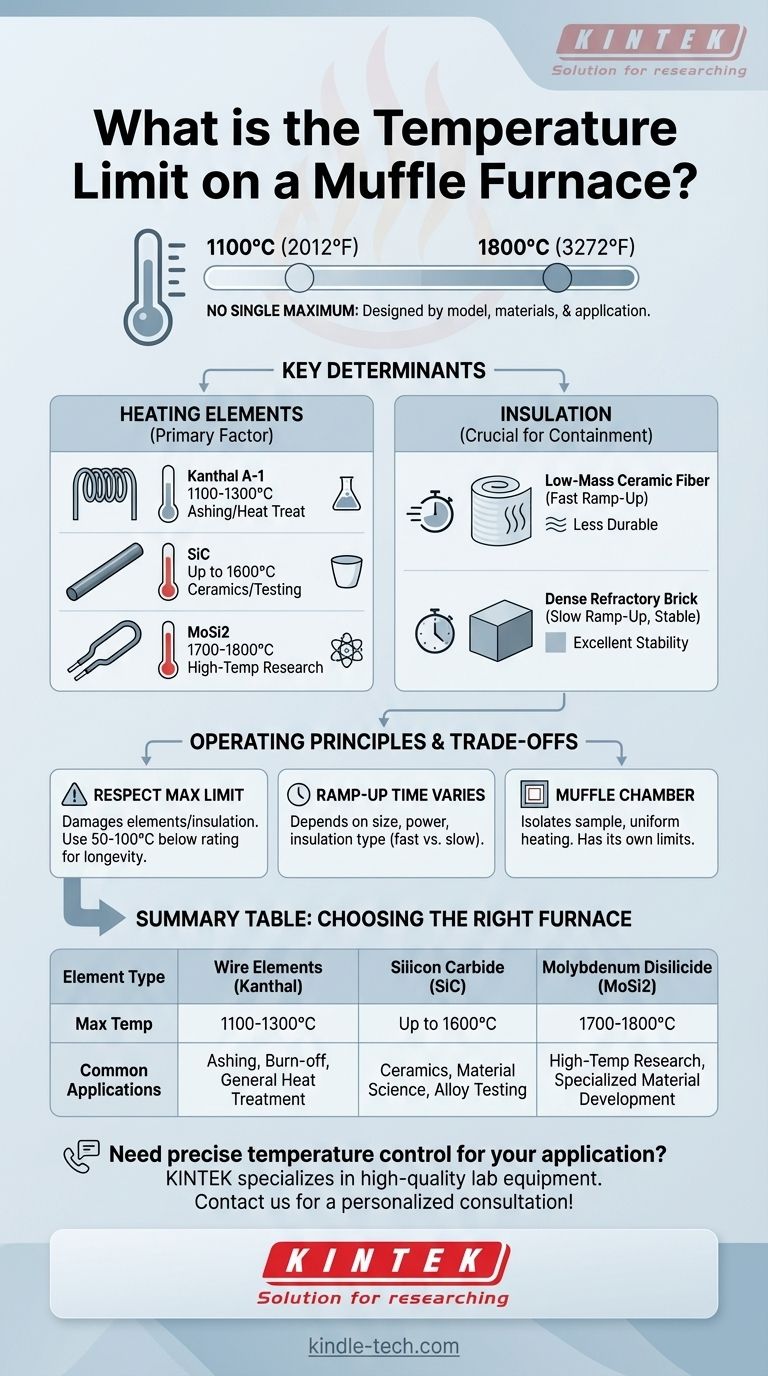

There is no single maximum temperature for a muffle furnace. The temperature limit is determined entirely by the specific model's design, materials, and intended application. Commercially available muffle furnaces have maximum operating temperatures that typically range from 1100°C (2012°F) to as high as 1800°C (3272°F).

The critical takeaway is that a muffle furnace's temperature limit is not a generic value but a specific engineering constraint. This limit is dictated by the materials used for its heating elements and thermal insulation, and exceeding it will cause permanent damage.

What Determines a Muffle Furnace's Temperature Limit?

The wide range in maximum temperatures exists because furnaces are built for different purposes, using different technologies. The two most critical components that define this limit are the heating elements and the insulation.

The Role of Heating Elements

The material used for the electrical heating elements is the primary factor limiting the furnace's peak temperature. Different materials have different maximum service temperatures before they degrade or fail.

-

Wire Elements (e.g., Kanthal A-1): Commonly found in general-purpose lab furnaces, these iron-chromium-aluminum alloys are robust and cost-effective, typically reaching maximum temperatures of 1100°C to 1300°C.

-

Silicon Carbide (SiC): For higher temperature applications like materials testing and small-scale ceramics, SiC rods are used. These allow for operating temperatures up to 1600°C.

-

Molybdenum Disilicide (MoSi2): These advanced ceramic elements are used in high-performance furnaces for research applications. They can achieve the highest temperatures, often reaching 1700°C to 1800°C.

The Importance of Insulation

A furnace can only reach and maintain a high temperature if it can effectively contain the heat. The type and quality of the insulation, or refractory material, are crucial.

Low-mass ceramic fiber insulation allows a furnace to heat up very quickly (sometimes in as little as 20 minutes) but may be less durable over time.

Denser refractory brick insulation has a much higher thermal mass, meaning it can take several hours to reach its maximum temperature. However, it is often more robust and provides excellent temperature stability.

Understanding the Trade-offs and Operating Principles

Simply knowing the maximum temperature is not enough for effective and safe operation. You must also understand the practical implications of a furnace's design.

Why You Must Respect the Rated Maximum

The manufacturer's maximum rated temperature is an absolute limit. Attempting to operate the furnace above this temperature will rapidly degrade the heating elements, damage the insulation, and can create a significant safety hazard.

Continuous operation at the absolute maximum temperature can also shorten the lifespan of the furnace components. For longevity, it is often best to use a furnace rated at least 50°C-100°C higher than your regular operating temperature.

Ramp-Up Time Is Not Universal

The time it takes for a furnace to reach its target temperature depends on its size, power, and insulation type.

A small, low-mass laboratory furnace may heat up quickly, while a larger production furnace with dense refractory bricks will take much longer. This "ramp-up" time is a critical factor to consider when planning your work.

The Muffle Chamber Itself

The term "muffle" refers to the inner chamber that isolates the sample from the direct radiation of the heating elements. This design protects the sample from contamination and provides more uniform heating. The material of this chamber also has its own temperature limits that contribute to the overall rating of the furnace.

Making the Right Choice for Your Application

To select the correct furnace, you must match its capabilities to your specific needs.

- If your primary focus is ashing, burn-off, or heat-treating common metals (below 1200°C): A standard furnace with Kanthal wire elements is the most practical and economical choice.

- If your primary focus is ceramics, material science, or alloy testing (1200°C - 1600°C): You require a more specialized furnace equipped with Silicon Carbide (SiC) heating elements.

- If your primary focus is high-temperature research or specialized material development (above 1600°C): Your only option is a high-performance model using Molybdenum Disilicide (MoSi2) elements and advanced insulation.

Ultimately, the furnace's official specification sheet is the only authoritative source for its operational limits.

Summary Table:

| Heating Element Type | Typical Max Temperature | Common Applications |

|---|---|---|

| Wire Elements (Kanthal) | 1100°C - 1300°C | Ashing, Burn-off, General Heat Treatment |

| Silicon Carbide (SiC) | Up to 1600°C | Ceramics, Material Science, Alloy Testing |

| Molybdenum Disilicide (MoSi2) | 1700°C - 1800°C | High-Temperature Research, Specialized Material Development |

Need a muffle furnace that perfectly matches your application's temperature requirements?

KINTEK specializes in providing high-quality lab equipment and consumables. Our experts can help you select the right furnace—from cost-effective standard models to high-performance research units—ensuring precise temperature control, safety, and durability for your laboratory.

Contact us today for a personalized consultation and get the right equipment for your specific needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the function of a high-temperature box furnace in silica membrane calcination? Achieve Precise Densification

- What are the steps of the sintering process? A Guide to Transforming Powder into Solid Parts

- What are the main components of a high-temperature muffle furnace? A Guide to the Core Systems

- What is the difference between a chamber furnace and a muffle furnace? Understanding Modern Lab Heating Equipment

- What role does a high-temperature air furnace play in HTL corrosion experiments? Ensure Data Integrity via Pre-Oxidation

- What temperature should a muffle furnace be for ash content? Achieve Accurate Results with the Right Heat

- What role does a high-temperature muffle furnace play in Cu-TiO2 thin films? Achieve Precise Phase Transformation

- What role does a laboratory high-temperature muffle furnace play in studying the thermal stability of solidification matrices?