In the pharmaceutical industry, a muffle furnace is a critical tool for quality control and analytical chemistry. It is primarily used to perform "ashing"—a process of high-temperature combustion that removes all organic material from a sample to precisely measure its inorganic content. This analysis is fundamental for drug inspection, determining purity, and preparing samples for further elemental testing.

The core challenge in pharmaceutical analysis is verifying a drug's purity and composition. A muffle furnace solves this by providing an ultra-clean, high-temperature environment to isolate the non-combustible components of a sample, which is a direct and reliable indicator of its inorganic makeup and potential impurities.

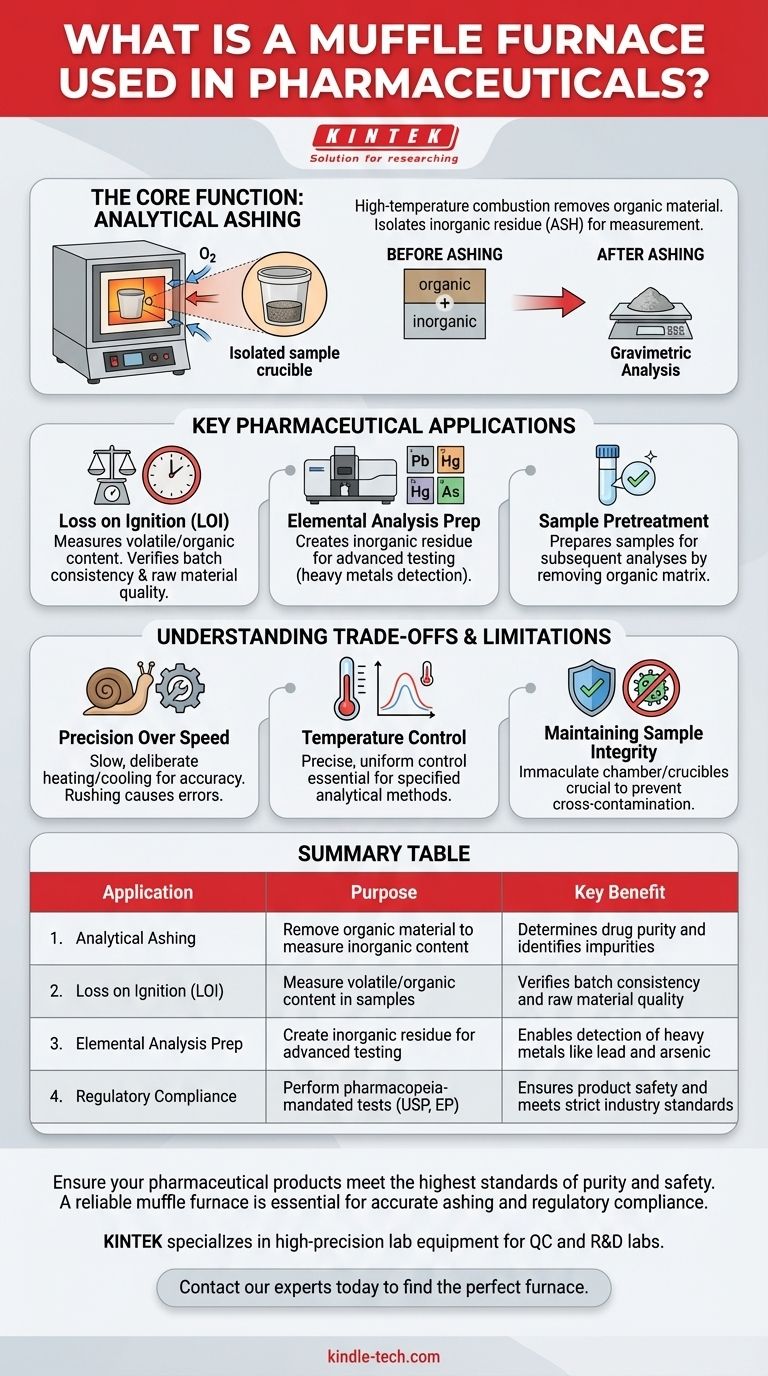

The Core Function: Analytical Ashing for Quality Control

A muffle furnace is not just an oven; it is a precision instrument designed for destructive analysis. Its function is to reveal what remains when all organic matter is burned away.

What is Ashing?

Ashing is the process of heating a substance at a high temperature in the presence of oxygen. This completely burns off all organic and volatile compounds, such as the active pharmaceutical ingredient (API) and organic excipients.

The material left behind is a small amount of residue known as ash. This ash consists entirely of inorganic materials, such as mineral impurities, inorganic salts, or metallic catalysts.

Why Ash Content Matters

The amount and composition of this ash are critical data points in pharmaceuticals. A high or unexpected ash content can signify contamination, the presence of heavy metals, or inconsistencies in the manufacturing process.

This process, often called gravimetric analysis, involves weighing the sample before and after ashing. The difference provides a precise measurement of the organic and inorganic content, which is a key test for regulatory compliance and product safety.

The Role of the "Muffle"

The defining feature of a muffle furnace is the muffle itself—a chamber that isolates the sample from the heating elements. This design prevents contamination from the combustion byproducts of the heating fuel or from degradation of the elements themselves.

For pharmaceutical analysis, where parts-per-million accuracy is essential, this ensures that the resulting ash is purely from the drug sample and not from the furnace.

Key Pharmaceutical Applications

The primary use of ashing leads to several standard analytical tests required by pharmacopeias worldwide.

Loss on Ignition (LOI)

This is one of the most common applications. A sample is weighed, heated in the furnace to a specific temperature for a set time, cooled, and re-weighed. The "loss on ignition" represents the mass of volatile materials burned off.

This test is used to determine the content of moisture, volatile matter, and overall organic components in a raw material or final drug product.

Elemental and Compositional Analysis

The ash produced by the muffle furnace is often just the first step. This inorganic residue can then be dissolved and analyzed using more advanced techniques, such as Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) analysis.

This allows scientists to identify and quantify specific elements, especially toxic heavy metals like lead, mercury, or arsenic, ensuring they are below safe limits.

Sample Pretreatment

Some advanced analytical methods require samples to be in an inorganic form. The muffle furnace serves as an essential pretreatment tool, reliably preparing samples for these subsequent analyses by cleanly removing the organic matrix.

Understanding the Trade-offs and Limitations

While highly effective, a muffle furnace is a specialized tool with specific operational principles that must be respected.

Precision Over Speed

Muffle furnaces are designed for accuracy and temperature uniformity, not speed. The heating and cooling cycles are often slow and deliberate to ensure complete combustion and prevent thermal shock to the sample or the furnace chamber. Rushing the process can lead to incomplete ashing and inaccurate results.

The Critical Need for Temperature Control

Different analytical methods specify exact temperatures and ramp rates. A high-quality furnace provides precise, uniform temperature control throughout the chamber.

Inconsistent heat zones can cause parts of the sample to ash incompletely, skewing the final weight and invalidating the test.

Maintaining Sample Integrity

The entire purpose of the muffle design is to prevent contamination. Users must ensure the ceramic muffle chamber and sample crucibles are impeccably clean to avoid cross-contamination between runs, which is an unacceptable error in a pharmaceutical setting.

Making the Right Choice for Your Goal

Your specific analytical goal will determine how you use the muffle furnace.

- If your primary focus is routine quality control: Use the furnace for standardized "loss-on-ignition" and "residue on ignition" tests to verify the purity and consistency of raw materials and finished product batches.

- If your primary focus is research and development: Employ the furnace as a sample preparation tool to create clean, inorganic residues for advanced elemental analysis and the characterization of new formulations.

- If your primary focus is regulatory compliance: Ensure your furnace's temperature controller is rigorously calibrated and the entire process is validated to meet the specific standards outlined in pharmacopeias (e.g., USP, EP, JP).

Ultimately, the muffle furnace serves as a gatekeeper for quality, providing the definitive data needed to ensure the purity and safety of pharmaceutical products.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Analytical Ashing | Remove organic material to measure inorganic content | Determines drug purity and identifies impurities |

| Loss on Ignition (LOI) | Measure volatile/organic content in samples | Verifies batch consistency and raw material quality |

| Elemental Analysis Prep | Create inorganic residue for advanced testing | Enables detection of heavy metals like lead and arsenic |

| Regulatory Compliance | Perform pharmacopeia-mandated tests (USP, EP) | Ensures product safety and meets strict industry standards |

Ensure your pharmaceutical products meet the highest standards of purity and safety.

A reliable muffle furnace is essential for accurate ashing, loss-on-ignition testing, and regulatory compliance. KINTEK specializes in high-precision lab equipment, including muffle furnaces designed for the exacting needs of pharmaceutical quality control and R&D labs.

Let us help you enhance your analytical capabilities. Contact our experts today to find the perfect furnace for your specific applications—from routine QC to advanced research.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the burning temperature of a furnace? From 200°C to 3000°C, It Depends on Your Needs

- What is the critical point of heat treatment? Master the Key to Steel Transformation

- What do you use a muffle furnace for? Achieve Contamination-Free High-Temperature Processing

- What is the hottest temperature a furnace? From 1100°C to 2000°C+

- Does melting require increase in temperature? Understanding Latent Heat and Phase Changes