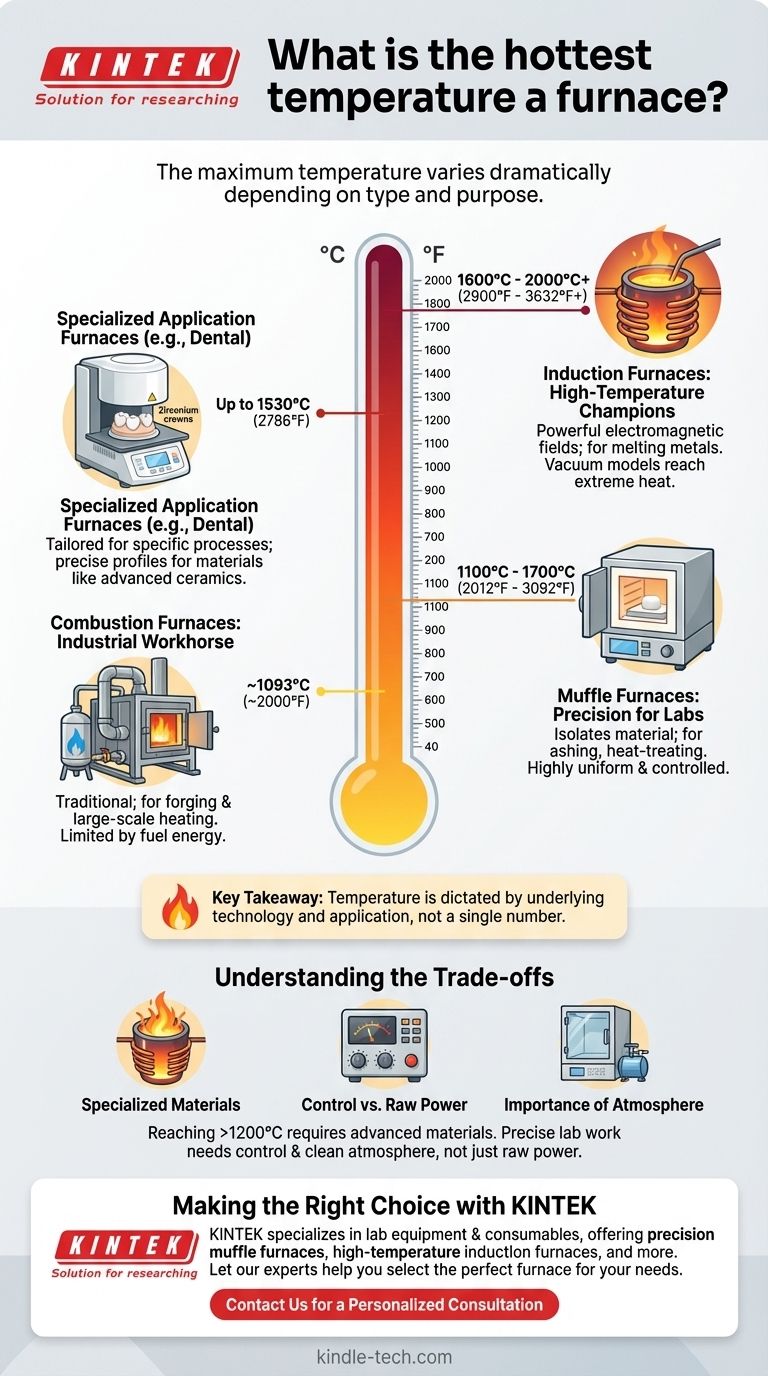

The maximum temperature of a furnace varies dramatically depending on its type and intended purpose. While a common natural gas furnace might operate around 1093°C (2000°F), highly specialized industrial units like vacuum induction furnaces can reach extreme temperatures of 2000°C (3632°F) or higher.

The key takeaway is that "furnace" is a broad category. The maximum temperature is not a single number but is instead dictated by the furnace's underlying technology—such as combustion, electrical resistance, or induction—and its specific industrial or laboratory application.

Why Furnace Temperature Varies So Widely

A furnace is simply a device designed to generate and contain high heat. However, the mechanism used to generate that heat and the materials used to contain it place fundamental limits on its maximum temperature.

A home heating unit and an industrial smelter are vastly different machines, each optimized for a completely different task and temperature range.

A Breakdown of Furnace Types and Temperatures

Understanding the different heating methods is the best way to understand the different temperature capabilities. Each design is engineered for a specific set of tasks.

Induction Furnaces: The High-Temperature Champions

Induction furnaces use powerful electromagnetic fields to heat conductive materials like metal. By inducing an electric current directly within the material itself, they can achieve exceptionally high temperatures very quickly.

Vacuum induction melting furnaces are among the most powerful, capable of reaching 2000°C (3632°F). Smaller induction furnaces used for melting metals typically reach 1600°C (2900°F).

Muffle Furnaces: Precision for Labs

A muffle furnace is an oven-like furnace that isolates the material being heated from the direct heat source. This prevents contamination from combustion byproducts and allows for highly uniform and controlled heating.

They are common in laboratories for applications like ashing samples or heat-treating materials. Their maximum temperatures typically range from 1100°C to 1700°C (2012°F to 3092°F), with many common models operating up to 1200°C (2192°F).

Combustion Furnaces: The Industrial Workhorse

These are the most traditional furnaces, burning a fuel like natural gas to generate heat. They are robust and effective for a wide range of industrial processes, from forging to large-scale heating.

A typical natural gas furnace can reach temperatures around 1093°C (2000°F). While effective, they are limited by the energy output of the fuel and heat loss to the environment.

Specialized Application Furnaces

Many industries require furnaces tailored to a very specific process. A dental furnace, for example, is designed to process materials like zirconium oxides for crowns and bridges.

These units are optimized for precision temperature profiles and can reach a maximum of 1530°C (2786°F) to handle these advanced ceramics.

Understanding the Trade-offs

Choosing a furnace isn't just about finding the highest possible temperature. The right tool depends on a balance of capability, control, and cost.

Higher Temperatures Demand Specialized Materials

Reaching and containing temperatures above 1200°C requires advanced refractory materials and insulation. This significantly increases the cost and complexity of the furnace.

Control vs. Raw Power

An induction furnace provides immense raw power for melting, but a muffle furnace offers the precise temperature control and clean atmosphere needed for delicate lab work. The goal is not always just maximum heat, but the right heat profile.

The Importance of Atmosphere

For many processes, controlling the atmosphere inside the furnace is as critical as the temperature. A vacuum furnace, for instance, removes air to prevent oxidation when working with reactive metals at high temperatures.

Making the Right Choice for Your Goal

The correct furnace is always the one that matches your specific application.

- If your primary focus is melting high-temperature metals like steel or platinum: An induction furnace is the required technology, capable of reaching 1600°C to 2000°C.

- If your primary focus is precise lab work, heat-treating, or firing ceramics: A muffle furnace provides the clean atmosphere and exact control needed in the 1100°C to 1700°C range.

- If your primary focus is general forging or industrial heating: A robust natural gas combustion furnace provides cost-effective heat up to around 1100°C.

Ultimately, selecting the right furnace begins with a clear understanding of your material and your process needs.

Summary Table:

| Furnace Type | Typical Max Temperature | Primary Applications |

|---|---|---|

| Induction Furnace | 1600°C - 2000°C+ | Metal melting, high-temperature processing |

| Muffle Furnace | 1100°C - 1700°C | Lab work, heat-treating, ceramics firing |

| Combustion Furnace | ~1100°C | Industrial heating, forging |

| Dental Furnace | Up to 1530°C | Zirconium oxide processing |

Need the right furnace for your specific temperature and application requirements? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision muffle furnaces, high-temperature induction furnaces, and more. Our experts will help you select the perfect furnace to match your material and process goals. Contact us today for a personalized consultation!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between muffle furnace and air oven? Choose the Right Tool for Your Thermal Process

- How is heat transferred in a furnace? Master Radiation, Convection & Conduction

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- Is a furnace endothermic or exothermic? Uncover the Science of Home Heating

- What are the safety precautions for heat experiment? Essential Steps to Prevent Lab Burns and Accidents