At its core, a vacuum brazing furnace is a specialized piece of industrial equipment that joins materials together using a filler metal in a high-vacuum environment. By removing air and other reactive gases, the furnace creates an exceptionally clean, controlled atmosphere that prevents oxidation during the heating process. This results in incredibly strong, pure, and precise joints without the need for chemical fluxes.

The crucial insight is that the vacuum is not merely an empty space; it is an active component of the brazing process. It acts as the ultimate "flux," protecting the metal surfaces and enabling the creation of superior joints that are impossible to achieve with conventional methods.

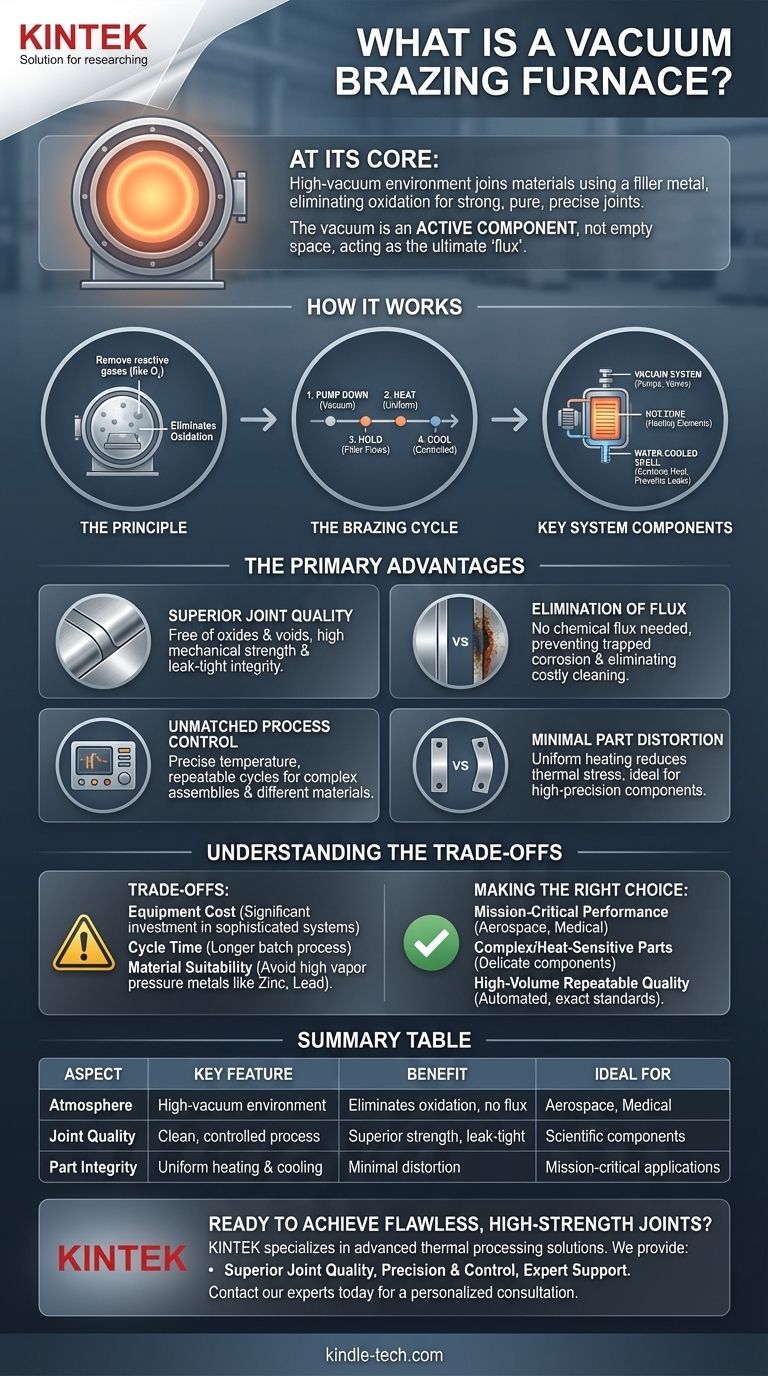

How a Vacuum Brazing Furnace Works

A vacuum furnace isn't just a hot box; it's a sophisticated system designed for absolute control over the joining environment. The process leverages fundamental physics to achieve its remarkable results.

The Principle: A Controlled Atmosphere

The primary function of the vacuum is to remove reactive gases, especially oxygen. At the high temperatures required for brazing, metals readily oxidize, which prevents the filler metal from properly wetting and bonding to the base materials. By operating in a vacuum, this entire failure mode is eliminated.

The Brazing Cycle

The process is methodical and highly repeatable. An operator assembles the components with the filler metal pre-placed at the joint, loads them into the furnace, and initiates a pre-programmed heating cycle. The system then automatically pumps down the chamber to the required vacuum level, heats the parts uniformly to the brazing temperature, holds for a set time to allow the filler to flow, and cools the assembly in a controlled manner.

Key System Components

A vacuum brazing furnace consists of several critical subsystems. The vacuum system, composed of pumps, valves, and gauges, creates and maintains the low-pressure environment. The hot zone contains the heating elements and is designed for exceptional temperature uniformity. Finally, a water-cooled furnace shell contains the heat and prevents leaks, preserving the integrity of the vacuum.

The Primary Advantages of Vacuum Brazing

Choosing this technology is a deliberate decision to prioritize quality, precision, and repeatability. The benefits are significant and directly address the common failures seen in other joining processes.

Superior Joint Quality

By eliminating atmospheric contamination, vacuum brazing produces joints that are free of oxides and voids. This results in a metallurgically sound bond with outstanding mechanical strength and leak-tight integrity.

Elimination of Flux

Conventional brazing requires a chemical flux to clean the metal surfaces. This flux can become trapped in the joint, causing corrosion and weakness over time. A vacuum furnace makes flux entirely unnecessary, which also eliminates the need for aggressive and costly post-brazing cleaning operations.

Unmatched Process Control

Modern vacuum furnaces offer incredibly precise and repeatable temperature control. This allows for the successful joining of complex assemblies, delicate components, and even materials with different melting points. The even heating and cooling cycles minimize thermal stress on the parts.

Minimal Part Distortion

Unlike welding or torch brazing, which introduce intense, localized heat, a vacuum furnace heats the entire assembly uniformly. This controlled thermal cycle significantly reduces the risk of warping and distortion, a critical advantage for high-precision components.

Understanding the Trade-offs

No process is perfect for every application. Objectivity requires acknowledging the specific constraints of vacuum furnace brazing.

Equipment Cost

Vacuum furnaces represent a significant capital investment. The sophisticated vacuum pumps, control systems, and high-temperature hot zones make them more expensive than simpler brazing equipment like torches or induction heaters.

Cycle Time

The process is inherently batch-oriented and methodical. The time required to pump down the chamber, run the heating profile, and cool the load means cycle times are typically longer than for other joining methods. This makes it less suitable for single-piece, high-speed production lines.

Material Suitability

The vacuum environment is not ideal for all materials. Metals with high vapor pressures, such as zinc, cadmium, or lead, can "outgas" at high temperatures. This process contaminates the furnace and can interfere with the quality of the brazed joint.

Making the Right Choice for Your Goal

Selecting vacuum brazing depends entirely on your application's specific technical and quality requirements.

- If your primary focus is mission-critical performance: This process is the standard in aerospace, medical, and scientific applications for creating flawless, high-strength joints where failure is not an option.

- If your primary focus is joining complex or heat-sensitive parts: The precise, uniform thermal control prevents damage to delicate components and ensures minimal distortion in high-precision assemblies.

- If your primary focus is high-volume, repeatable quality: The automated and programmable cycles ensure that every part is produced to the exact same high standard, eliminating operator-to-operator variability.

Ultimately, vacuum brazing provides an unparalleled level of control and quality for the most demanding engineering challenges.

Summary Table:

| Aspect | Key Feature | Benefit |

|---|---|---|

| Atmosphere | High-vacuum environment | Eliminates oxidation, no flux required |

| Joint Quality | Clean, controlled process | Superior strength, leak-tight integrity |

| Part Integrity | Uniform heating and cooling | Minimal distortion, ideal for complex assemblies |

| Ideal For | Aerospace, medical, scientific components | Mission-critical applications where failure is not an option |

Ready to achieve flawless, high-strength joints for your most demanding components?

KINTEK specializes in advanced thermal processing solutions, including vacuum brazing furnaces. Our equipment is designed for the unparalleled quality and repeatability required in aerospace, medical, and high-tech manufacturing.

We provide:

- Superior Joint Quality: Produce strong, clean, and reliable bonds without flux.

- Precision and Control: Minimize distortion in complex or delicate assemblies.

- Expert Support: Leverage our deep application knowledge to optimize your process.

Let's discuss how a KINTEK vacuum brazing furnace can solve your toughest joining challenges. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the uses of furnace in industry? Powering Material Transformation and Manufacturing

- What is the use of resistance furnace? Achieve Precise, Clean High-Temperature Processing

- How does a regenerator work? Mastering High-Efficiency Cyclical Heat Transfer

- What temperature do you braze aluminium? Master the Critical Temperature Window for Strong Joints

- Which furnace is used for heating metals? Match the Right Technology to Your Metalworking Goal

- What is the function of the vacuum pressure impregnation tank in the PIP process? Achieve High-Density CMCs

- What is the negative effect of quenching steel? Manage Internal Stress and Prevent Cracking

- What is the role of an industrial electric furnace in the preparation of biomass tar reforming catalysts? Vital Insights