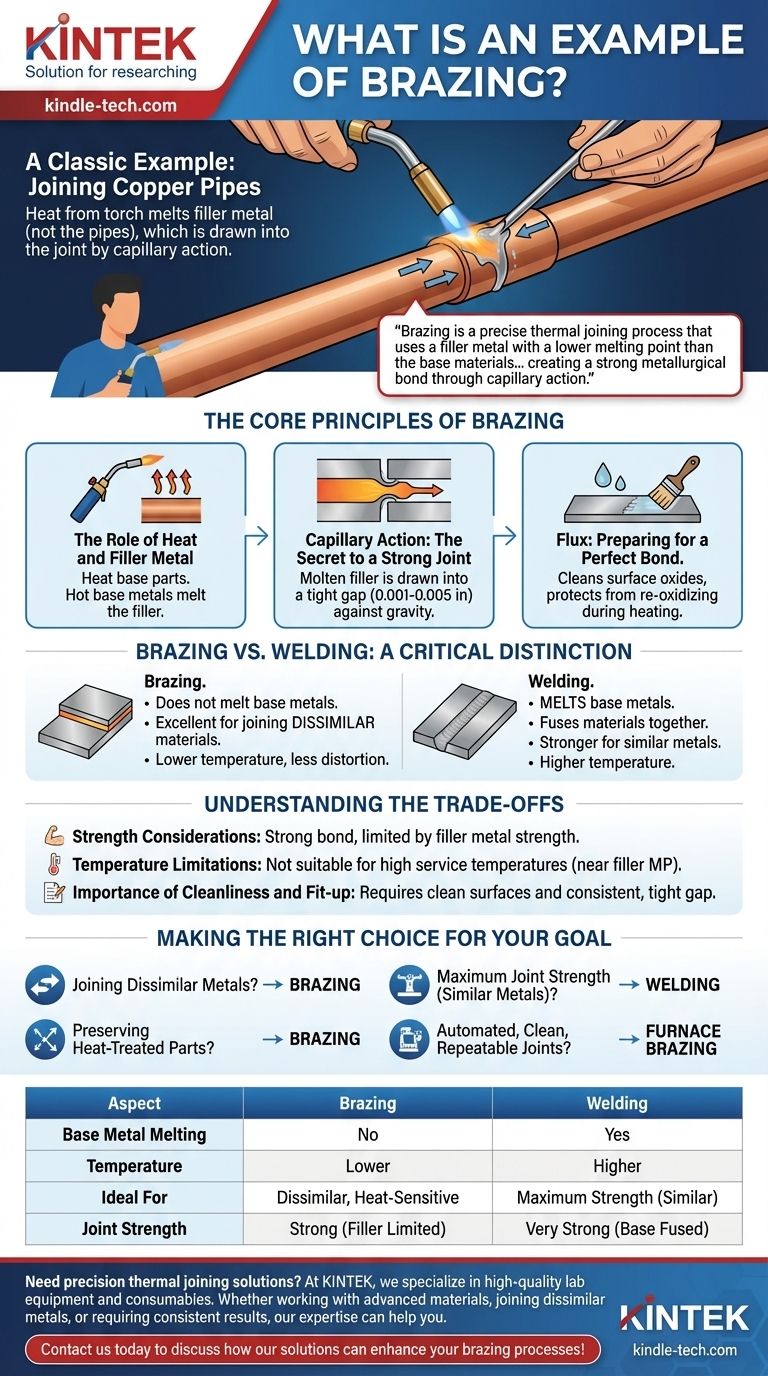

A classic example of brazing is the process of joining copper pipes in plumbing and HVAC systems. In this application, a torch heats the copper pipes at the joint, and once they are hot enough, a filler metal alloy (often a silver alloy) is touched to the seam. The hot pipes instantly melt the filler metal, which is then drawn into the tight gap between the two pieces of pipe by capillary action, creating a strong, leak-proof bond without melting the copper itself.

Brazing is a precise thermal joining process that uses a filler metal with a lower melting point than the base materials. The key principle is that the base metals are heated to melt the filler—not the other way around—creating a strong metallurgical bond through a phenomenon called capillary action.

The Core Principles of Brazing

To truly understand brazing, you need to look beyond the application and grasp the fundamental science that makes it work. The process is a careful balance of temperature, material science, and physics.

The Role of Heat and Filler Metal

Brazing operates below the melting point of the base materials being joined. Heat from a torch or furnace is applied broadly to the base parts around the joint area.

The filler metal, in wire or rod form, is only introduced once the base parts have reached the correct temperature. This is a critical step; the hot base metals are what melt the filler, ensuring the heat is exactly where it needs to be.

Capillary Action: The Secret to a Strong Joint

The real magic of brazing is capillary action. This is the tendency of a liquid to be drawn into a very narrow space, even against gravity.

For this to work, the parts must have a very specific, tight gap between them (typically 0.001 to 0.005 inches). When the molten filler metal touches this gap, it is instantly pulled in, completely filling the space between the two surfaces and creating a formidable bond as it cools.

Flux: Preparing the Surface for a Perfect Bond

Metal surfaces naturally have an oxide layer that prevents the filler metal from properly adhering. This is where flux comes in.

Flux is a chemical cleaning agent applied to the joint before heating. It melts and becomes active, dissolving oxides and protecting the surfaces from re-oxidizing during the heating process, ensuring the molten filler can bond directly with the clean base metal.

Brazing vs. Welding: A Critical Distinction

Many people confuse brazing with welding, but they are fundamentally different processes with distinct advantages and use cases. Understanding this difference is key to appreciating why brazing is chosen for certain applications.

Temperature and the Base Metal

The most significant difference is that welding melts the base metals. A weld fuses materials by melting them together, often with a filler material, to form a single, continuous piece upon cooling.

Brazing never melts the base metals. This lower-temperature process is less likely to distort the parts, change their metallurgical properties (like heat treatment), or create thermal stress.

Joining Dissimilar Materials

Because brazing doesn't melt the base metals, it is exceptionally effective at joining materials with very different properties, such as copper to steel or carbide to steel. This is extremely difficult or impossible to achieve with most traditional welding methods.

Understanding the Trade-offs

While powerful, brazing is not a universal solution. It's essential to recognize its limitations to know when it is the appropriate choice for a technical problem.

Strength Considerations

A properly brazed joint is very strong, as the filler alloy forms a metallurgical bond with the base materials. However, the strength of the joint is ultimately limited by the strength of the filler metal itself, which is typically lower than that of the base metals. A welded joint, which fuses the base metals, is often stronger.

Temperature Limitations

The filler metals used in brazing have a lower melting point than the base metals. This means a brazed component cannot be used in an environment where service temperatures would approach the melting point of the filler alloy, as the joint would fail.

The Importance of Cleanliness and Fit-up

Brazing is far less forgiving than welding when it comes to preparation. The success of the joint is entirely dependent on having clean surfaces and a consistent, tight gap between the parts to enable proper capillary action.

Making the Right Choice for Your Goal

Selecting the right joining method depends entirely on the requirements of your project.

- If your primary focus is joining dissimilar metals (e.g., steel to copper): Brazing is almost always the superior and more practical choice.

- If your primary focus is preserving the properties of heat-treated parts: The lower temperatures of brazing make it the ideal method to avoid distortion or metallurgical damage.

- If your primary focus is achieving maximum joint strength in similar metals: Welding is typically the better option, as it fuses the base materials directly.

- If your primary focus is creating a large number of clean, repeatable joints in an automated fashion: Furnace brazing is a highly efficient and widely used industrial manufacturing process.

Ultimately, understanding brazing provides you with a versatile and precise tool for solving complex engineering challenges.

Summary Table:

| Aspect | Brazing | Welding |

|---|---|---|

| Base Metal Melting | No | Yes |

| Temperature | Lower (below base metal melting point) | Higher (melts base metals) |

| Ideal For | Dissimilar metals, heat-sensitive parts | Maximum strength in similar metals |

| Joint Strength | Strong, limited by filler metal | Very strong, fuses base metals |

Need precision thermal joining solutions for your lab or production line?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific needs. Whether you're working with advanced materials, joining dissimilar metals, or require consistent, repeatable results, our expertise can help you achieve superior outcomes.

Contact us today to discuss how our solutions can enhance your brazing processes and improve your operational efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

People Also Ask

- How do you make an inert atmosphere? Master Safe, Pure Processes with Inerting

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- What is an example of an inert atmosphere? Discover the Best Gas for Your Process

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes