To be direct, Atmospheric Pressure Chemical Vapor Deposition (APCVD) is a method for creating a thin film of solid material on a surface. It works by exposing a substrate to volatile chemical precursors at standard atmospheric pressure, which then react or decompose on the substrate's hot surface to form the desired coating. This process is distinct from other forms of Chemical Vapor Deposition (CVD) that require a vacuum to operate.

The crucial difference is in the name: Atmospheric Pressure. Unlike many deposition techniques that rely on expensive and slow vacuum chambers, APCVD is valued for its high speed and simpler equipment, making it a cost-effective choice for large-scale production where ultimate film purity is not the primary concern.

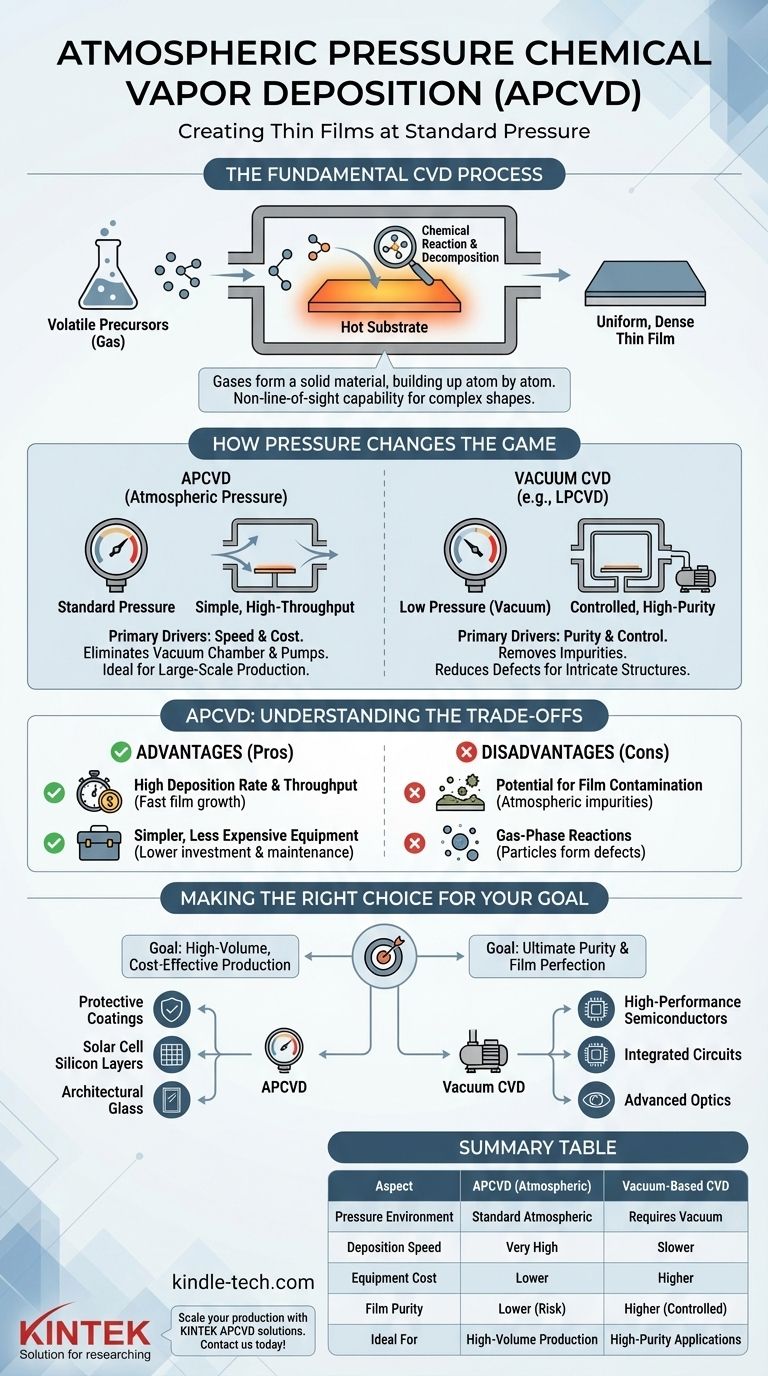

The Fundamental CVD Process

To understand APCVD, one must first grasp the core principle of Chemical Vapor Deposition (CVD). It is a family of processes, not a single technique, all sharing a common mechanism.

The Role of Precursors

At its heart, CVD is like a highly controlled chemical spray-painting process. Instead of paint, it uses one or more volatile chemical gases called precursors. These precursors contain the atoms needed for the final film (e.g., silicon, carbon, or a metal).

The Importance of Temperature

The precursors are introduced into a reaction chamber containing the object to be coated, known as the substrate. The substrate is heated to a specific temperature, which provides the energy needed to trigger a chemical reaction.

The Result: A Uniform Film

When the precursor gases come into contact with the hot substrate, they react or decompose, leaving behind a solid material that bonds to the surface. Over time, this material builds up atom by atom, creating a highly uniform and dense film. Because the precursors are gases, they can coat complex, three-dimensional shapes evenly, an advantage known as its non-line-of-sight capability.

How Pressure Changes the Game

The "Atmospheric Pressure" in APCVD is the single most important variable that defines its characteristics, advantages, and limitations. It fundamentally changes the operating environment compared to vacuum-based CVD methods.

Why Operate at Atmospheric Pressure?

The primary drivers for using APCVD are speed and cost. By operating at normal atmospheric pressure, the process eliminates the need for expensive vacuum pumps and sealed chambers. This not only reduces equipment cost and complexity but also allows for continuous, high-throughput processing, which is ideal for industrial manufacturing.

Why Use a Vacuum? (The Alternative)

Processes like Low-Pressure CVD (LPCVD) operate in a vacuum for a key reason: purity and control. A vacuum removes unwanted atmospheric gases like nitrogen and oxygen that could accidentally get incorporated into the film as impurities. Lower pressure also increases the "mean free path" of precursor molecules, allowing them to travel further without colliding, which can lead to more uniform films with fewer defects, especially on intricate structures.

Understanding the Trade-offs of APCVD

Choosing APCVD involves a clear set of engineering trade-offs. It excels in some areas and is unsuitable for others.

Advantage: High Deposition Rate and Throughput

Because of the high concentration of precursor molecules at atmospheric pressure, the chemical reactions happen very quickly. This results in a much faster film growth rate compared to vacuum methods, making APCVD highly efficient for mass production.

Advantage: Simpler, Less Expensive Equipment

Eliminating the need for a vacuum system dramatically simplifies the reactor design. This lowers the initial capital investment and reduces ongoing maintenance costs, making the technology more accessible.

Disadvantage: Potential for Film Contamination

The primary drawback is the presence of the atmosphere itself. Ambient air can introduce impurities (like oxides or nitrides) into the growing film, which can be unacceptable for high-performance applications like microelectronics.

Disadvantage: Gas-Phase Reactions

At higher pressure, precursor molecules are more likely to collide and react with each other in the gas phase before they even reach the substrate. This can form tiny particles that then fall onto the surface, creating defects and reducing the quality of the film.

Making the Right Choice for Your Goal

The decision to use APCVD hinges entirely on the requirements of the final product.

- If your primary focus is high-volume, cost-effective production: APCVD is an excellent choice for applications like depositing protective coatings, creating the silicon layers for solar cells, or coating architectural glass.

- If your primary focus is ultimate purity and film perfection: A vacuum-based method like LPCVD is necessary for fabricating high-performance semiconductor devices, integrated circuits, and advanced optical components.

Ultimately, APCVD leverages simplicity and speed by trading the pristine environment of a vacuum for the efficiency of operating in the open air.

Summary Table:

| Aspect | APCVD (Atmospheric Pressure) | Vacuum-Based CVD (e.g., LPCVD) |

|---|---|---|

| Pressure Environment | Standard atmospheric pressure | Requires vacuum chamber |

| Deposition Speed | Very high | Slower |

| Equipment Cost | Lower (no vacuum pumps) | Higher |

| Film Purity | Lower (risk of contamination) | Higher (controlled environment) |

| Ideal For | High-volume production (e.g., solar cells, glass coatings) | High-purity applications (e.g., semiconductors) |

Ready to scale your thin-film production with a fast, cost-effective solution? KINTEK specializes in lab equipment and consumables, offering APCVD systems designed for high-throughput manufacturing. Our expertise ensures you get the right equipment for depositing protective coatings, silicon layers for solar cells, and more. Contact us today to discuss how our APCVD solutions can enhance your laboratory's efficiency and reduce costs!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the CVD process in nanotechnology? Master Atomic-Level Material Fabrication

- How does Radio Frequency Chemical Vapor Infiltration (RF-CVI) equipment improve deposition efficiency? Maximize Speed

- What is the pressure of RF sputtering? Optimize Your Thin Film Deposition Process

- Why is chemical vapor deposition preferred over physical vapor deposition? Superior Conformality for Complex Parts

- What is the difference between MOCVD and MOVPE? They Are the Same Process

- What is the difference between RF and DC magnetron sputtering? Choose the Right Technique for Your Thin-Film Needs

- What temperature does LPCVD SiN require? Optimize Film Quality with High-Temperature Processing

- Why is a heating stage required for substrate preheating during the LCVD process? Enhance Film Uniformity & Stability