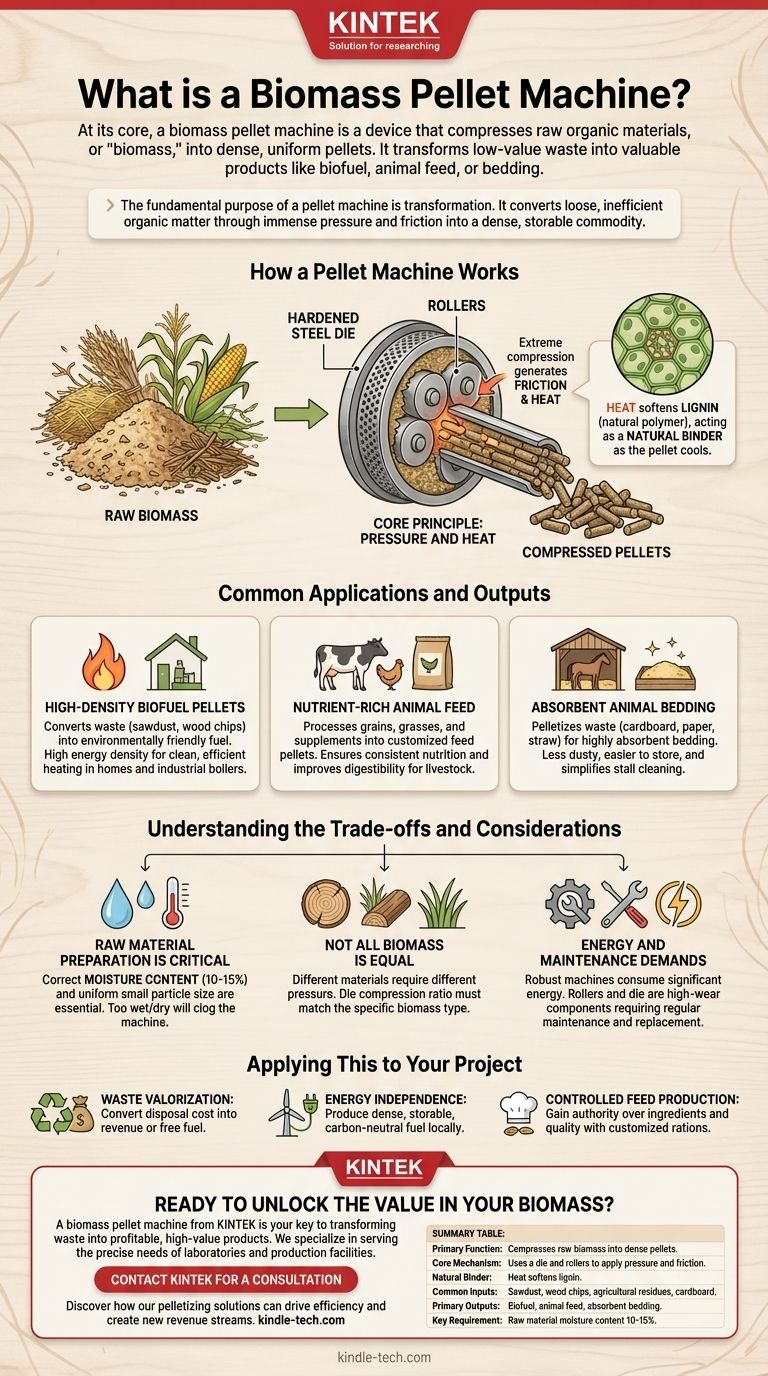

At its core, a biomass pellet machine is a device that compresses raw organic materials, or "biomass," into dense, uniform pellets. It is engineered to transform low-value or waste materials like sawdust, agricultural residues, or cardboard into valuable, easy-to-handle products such as biofuel, animal feed, or absorbent bedding.

The fundamental purpose of a pellet machine is transformation. It takes loose, inefficient organic matter and, through immense pressure and friction, converts it into a dense, storable, and valuable commodity.

How a Pellet Machine Works

Understanding the mechanism reveals how simple raw materials become a refined product. The process relies on basic physics rather than complex chemical reactions.

The Core Principle: Pressure and Heat

A pellet machine operates by forcing the raw biomass through a hardened steel die, which is a thick metal plate drilled with numerous small holes. The extreme compression generates significant friction and heat.

Key Components: The Die and Rollers

The central components are the die and a set of rollers. As the machine operates, the rollers continuously press the raw material against the inner surface of the die, forcing it through the holes. The material emerges on the other side as dense, compressed strands, which are then cut to a uniform pellet length.

The Role of Lignin

The heat generated by this friction is crucial. It softens the lignin, a natural polymer found in the cell walls of plants. This softened lignin acts as a natural binder, holding the compressed material together as the pellet cools and hardens, giving it durability without the need for artificial additives.

Common Applications and Outputs

The versatility of a pellet machine allows for the production of several distinct products, depending on the input material and machine configuration.

High-Density Biofuel Pellets

This is the most common application. Waste materials like sawdust, wood chips, and agricultural stalks are converted into environmentally friendly fuel. These pellets offer a high energy density and burn much more cleanly and efficiently than raw biomass, making them ideal for heating homes and industrial boilers.

Nutrient-Rich Animal Feed

By processing a specific mixture of grains, grasses, and nutritional supplements, the machine can produce customized feed pellets. This ensures consistent nutrition for livestock, poultry, and other animals. The heat involved in the process can also increase the digestibility of certain ingredients.

Absorbent Animal Bedding

Waste products like cardboard, paper, or straw can be pelletized to create highly absorbent animal bedding. Pelletized bedding is less dusty, easier to store, and simpler to clean out of stalls compared to loose material.

Understanding the Trade-offs and Considerations

While powerful, a pellet machine is not a "magic box." Achieving consistent, high-quality output requires careful management of the process.

Raw Material Preparation is Critical

The single most important factor for success is the condition of the input material. The biomass must have the correct moisture content (typically between 10-15%) and a uniform, small particle size. Material that is too wet or too dry will not form proper pellets and can clog the machine.

Not All Biomass is Equal

Different materials behave differently under pressure. Hardwoods require more force than softwoods, and agricultural grasses have different properties than wood fiber. The machine's die compression ratio must be matched to the specific type of biomass being processed to achieve optimal results.

Energy and Maintenance Demands

These are robust machines that consume a significant amount of energy to generate the necessary force. Furthermore, the rollers and die are high-wear components that are subjected to extreme pressure and abrasion. They require regular inspection, lubrication, and eventual replacement to maintain performance.

Applying This to Your Project

To determine if a pellet machine is the right solution, align its capabilities with your primary objective.

- If your primary focus is waste valorization: A pellet machine offers a direct path to convert a disposal cost (like sawdust) into a potential revenue stream or a source of free fuel.

- If your primary focus is energy independence: This technology enables you to produce a dense, storable, and carbon-neutral fuel source from locally available biomass.

- If your primary focus is controlled feed production: You gain complete authority over feed ingredients and quality, allowing for customized rations from your own raw materials.

Ultimately, a biomass pellet machine is a tool that empowers you to unlock the inherent value in raw organic matter.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Compresses raw biomass into dense, uniform pellets. |

| Core Mechanism | Uses a die and rollers to apply extreme pressure and friction. |

| Natural Binder | Heat softens lignin in the biomass, binding the pellet. |

| Common Inputs | Sawdust, wood chips, agricultural residues, cardboard. |

| Primary Outputs | Biofuel pellets, animal feed pellets, absorbent bedding. |

| Key Requirement | Raw material moisture content must be 10-15%. |

Ready to unlock the value in your biomass?

A biomass pellet machine from KINTEK is your key to transforming waste materials like sawdust and agricultural residues into profitable, high-value products. Whether your goal is to create sustainable biofuel, produce customized animal feed, or manufacture superior bedding, our robust lab and production equipment is engineered for reliability and optimal performance.

We specialize in serving the precise needs of laboratories and production facilities. Let our experts help you select the perfect machine for your specific materials and output goals.

Contact KINTELK today for a consultation and discover how our pelletizing solutions can drive efficiency and create new revenue streams for your operation.

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the cold CIP process? Achieve Uniform Density in Complex Powdered Parts

- How does a cold isostatic press improve microhardness uniformity? Achieving Consistency in TiC10/Cu-Al2O3 Composites

- In what ways does Cold Isostatic Pressing (CIP) enhance LiFePO4 battery performance? Boost Density and Conductivity

- What are the advantages of using a Cold Isostatic Press (CIP)? Achieve High Density in Ceramic Pellets

- What advantages does CIP equipment offer for W-TiC composites? Achieve High-Density, Defect-Free Materials