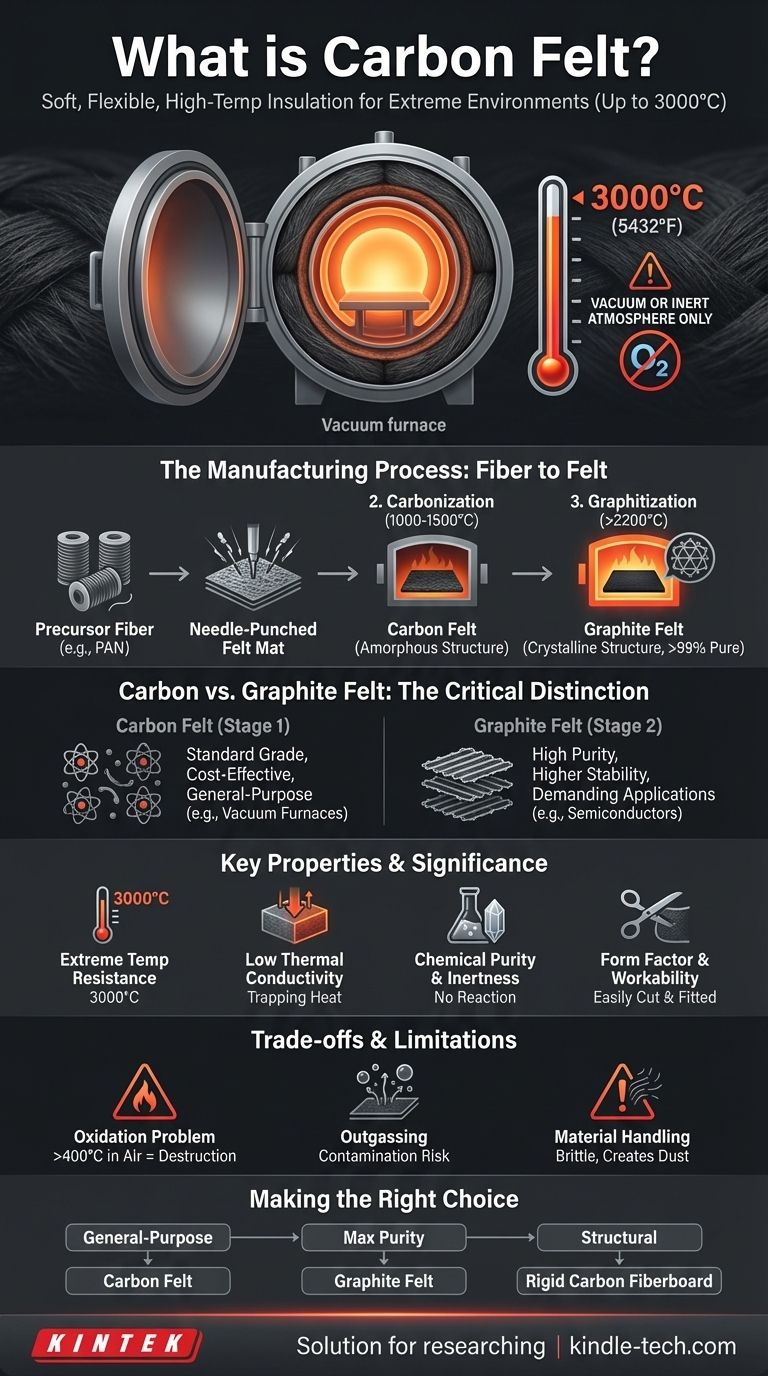

In essence, carbon felt is a soft, flexible, and highly effective insulation material engineered to withstand extreme temperatures in controlled environments. Unlike conventional insulation, it is designed to operate in vacuums or inert atmospheres where it can resist heat up to 3000°C (5432°F).

The critical concept to grasp is that carbon felt is not a general-purpose insulator. It is a specialized refractory material whose remarkable heat resistance is only realized in the absence of oxygen, making it indispensable for high-tech applications like vacuum furnaces.

The Manufacturing Process: From Fiber to Felt

Creating the Base Material

The journey begins with a precursor material, typically a synthetic fiber like polyacrylonitrile (PAN) or rayon. This base material is first processed into a non-woven felt mat through a needle-punching process.

This initial felt has no special thermal properties. The transformation happens in the next, high-temperature stages.

The Carbonization Step

The felt is heated in an inert atmosphere to a temperature of approximately 1000-1500°C. This process, called carbonization, burns off almost all non-carbon elements, leaving behind a material composed of amorphous carbon fibers.

The result of this first stage is carbon felt.

The Critical Distinction: Carbon vs. Graphite Felt

While often used interchangeably, carbon and graphite felt represent two distinct grades of material with different properties and applications. The difference lies in an additional processing step.

Stage 1: Carbon Felt

This is the standard grade produced after the initial carbonization. It is an excellent insulator but is less pure and has a more disordered atomic structure.

It serves as a cost-effective workhorse for many general-purpose high-temperature vacuum or inert gas applications.

Stage 2: Graphite Felt

To create graphite felt, carbon felt undergoes a second, much higher-temperature heat treatment, often exceeding 2200°C. This process, called graphitization, rearranges the amorphous carbon atoms into a more ordered, crystalline graphite structure.

This results in a material that is more than 99% pure carbon. Graphite felt offers higher thermal stability and is the preferred choice for the most demanding applications where purity is paramount.

Key Properties and Their Significance

Extreme Temperature Resistance

This is the material's defining characteristic. Its ability to remain stable at temperatures that would melt or vaporize most metals makes it essential for advanced manufacturing.

Remember, this property is entirely dependent on its environment. It requires a vacuum or a protective atmosphere of inert gas like argon.

Low Thermal Conductivity

Carbon and graphite felts are excellent insulators because their fibrous structure traps "dead space," dramatically slowing the transfer of heat.

This property is what allows a vacuum furnace to reach thousands of degrees on the inside while remaining relatively cool on the outside, protecting the equipment and ensuring process efficiency.

Chemical Purity and Inertness

Because it is composed almost entirely of carbon, the material is chemically inert and does not react with most process materials. This is crucial in industries like semiconductor manufacturing or crystal growth, where even minor contamination can ruin a product.

Form Factor and Workability

Unlike rigid ceramic insulation, carbon felt is soft and flexible. It can be easily cut with a knife and fitted around complex components, ensuring complete and efficient insulation coverage.

Understanding the Trade-offs and Limitations

The Oxidation Problem

The single most important limitation of carbon felt is its susceptibility to oxidation. In the presence of oxygen, it will rapidly burn away at temperatures above approximately 400°C (752°F).

This is why its use is strictly limited to vacuum or inert gas environments. Any air leak in a high-temperature furnace can lead to the complete destruction of the insulation pack.

Outgassing and Purity

Lower-grade carbon felts can contain residual binders or impurities that turn into gas at high temperatures—a phenomenon called outgassing. This can contaminate the vacuum environment and the product itself.

For applications requiring extreme purity, a pre-fired, high-purity graphite felt is necessary to minimize this risk.

Material Handling

While soft, the fibers can be brittle. This means the material can shed carbon dust and requires careful handling to maintain its structural integrity and avoid creating airborne particles.

Making the Right Choice for Your Application

- If your primary focus is general-purpose furnace insulation: Standard PAN-based carbon felt provides the most effective balance of performance and cost.

- If your primary focus is maximum purity and process stability: High-purity, pre-fired graphite felt is the correct choice to minimize contamination and outgassing.

- If your primary focus is structural integrity or machined components: Consider rigid carbon fiberboard, a densified version of felt that offers similar thermal properties in a solid, machinable form.

By understanding its properties and, more importantly, its environmental limitations, you can leverage carbon felt to achieve stable thermal control in the most demanding industrial environments.

Summary Table:

| Property | Carbon Felt | Graphite Felt |

|---|---|---|

| Max Temperature | Up to 3000°C (in inert/vacuum) | Up to 3000°C (in inert/vacuum) |

| Oxidation Limit | ~400°C (in air) | ~400°C (in air) |

| Purity | Standard grade | >99% pure carbon |

| Key Application | General-purpose furnace insulation | High-purity processes (e.g., semiconductors) |

| Form Factor | Soft, flexible, easily cut | Soft, flexible, easily cut |

Need reliable high-temperature insulation for your lab or industrial furnace?

KINTEK specializes in premium carbon and graphite felt solutions tailored for vacuum and inert atmosphere applications. Our materials ensure precise thermal control, chemical inertness, and process stability for your most demanding heat treatment processes.

➤ Contact our experts today to discuss the ideal insulation solution for your specific needs.

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Bomb Type Probe for Steelmaking Production Process

People Also Ask

- At what temperature does graphite thermal decompose? The Critical Role of Atmosphere

- How well does graphite transfer heat? Unlock Superior Thermal Management for Your Electronics

- Is a graphite melting point high or low? Discover Its Extreme Thermal Resilience

- How is synthetic graphite manufactured? A Deep Dive into the High-Temperature Process

- What is the maximum working temperature of graphite? Unlock High-Temp Performance with the Right Atmosphere