In essence, Chemical Vapor Deposition (CVD) is a process used to create high-purity, high-performance thin films on a surface. It works by introducing reactive gases (precursors) into a chamber, where they undergo a chemical reaction on a heated substrate, leaving behind a solid layer of the desired material. This method allows for the construction of materials layer by layer, offering exceptional control over thickness, purity, and structure.

Chemical Vapor Deposition is less like painting a surface and more like building it from the atom up. It uses gas-phase chemistry to construct exceptionally pure and uniform thin films, making it a cornerstone technology for manufacturing high-performance electronics and advanced materials.

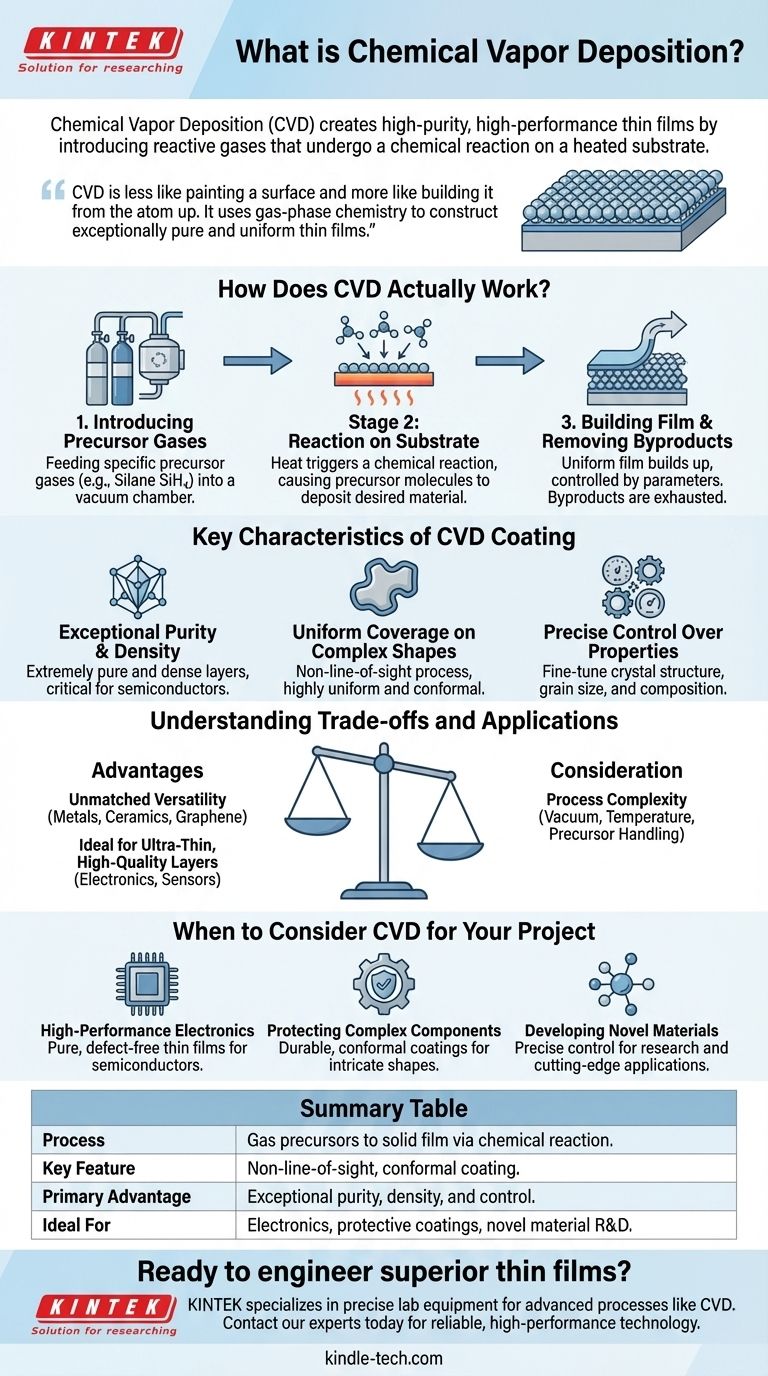

How Does CVD Actually Work?

At its core, CVD is a carefully controlled chemical reaction that transforms gases into a solid. The process can be broken down into a few fundamental stages.

Stage 1: Introducing the Reactant Gases

The process begins by feeding specific gases, known as precursors, into a reaction chamber that is typically under vacuum. These precursors contain the chemical elements needed for the final film.

For example, to deposit a film of pure silicon, a gas like silane (SiH₄) might be used as the precursor.

Stage 2: The Reaction on the Substrate

Inside the chamber, a base material, called the substrate, is heated to a precise temperature. When the precursor gases flow over this hot surface, the heat provides the energy needed to trigger a chemical reaction.

This reaction causes the precursor molecules to break apart, "depositing" the desired solid material directly onto the substrate surface.

Stage 3: Building the Film and Removing Byproducts

The solid material builds up on the substrate, forming a thin, uniform film. The thickness of this film is controlled with incredible precision by adjusting process parameters like time, temperature, and gas flow.

Any unwanted chemical elements from the reaction form gaseous byproducts. These are harmlessly swept out of the chamber, leaving behind an exceptionally pure final coating.

Key Characteristics of a CVD Coating

The reason CVD is so widely used is because of the superior qualities of the films it produces. It isn't just a coating; it's an engineered layer.

Exceptional Purity and Density

Because the process builds the film from purified gas precursors in a controlled environment, the resulting layers are extremely pure and dense. This is critical for applications like semiconductors, where even tiny impurities can ruin device performance.

Uniform Coverage on Complex Shapes

CVD is a non-line-of-sight process. The gas flows around the entire substrate, no matter how complex its shape. This results in a highly uniform, or conformal, coating that perfectly wraps around every feature of the component.

Precise Control Over Material Properties

By carefully adjusting the deposition parameters—such as temperature, pressure, and gas composition—engineers can fine-tune the final material. They can control the crystal structure, grain size, and even chemical composition, tailoring the film for a specific purpose.

Understanding the Trade-offs and Applications

CVD is a powerful but specialized tool. Choosing it requires understanding its primary advantages and inherent complexities.

Advantage: Unmatched Versatility

The process is fundamentally based on chemical reactions, which gives it enormous versatility. CVD can be used to deposit a vast range of materials, including metals, ceramics, alloys, and advanced compounds like graphene.

Advantage: Ideal for Ultra-Thin, High-Quality Layers

CVD excels at creating films that are both ultra-thin and structurally perfect. This makes it the leading method for manufacturing high-performance electronics, sensors, and optical components where quality at the nanoscale is paramount.

Consideration: Process Complexity

The primary trade-off is the complexity of the equipment and process. CVD requires a vacuum chamber, precise temperature control, and careful handling of volatile precursor gases. This makes it more suitable for high-value applications where performance justifies the investment.

When to Consider CVD for Your Project

CVD is the right choice when the quality and performance of a surface layer are non-negotiable.

- If your primary focus is high-performance electronics: CVD is the industry standard for creating the pure, defect-free thin films required for semiconductors and advanced sensors.

- If your primary focus is protecting complex components: The conformal nature of CVD makes it ideal for applying durable, low-friction, or thermally resistant coatings to parts with intricate shapes.

- If your primary focus is developing novel materials: CVD offers the precise control needed to engineer materials with specific crystalline structures and properties for research and cutting-edge applications.

Ultimately, Chemical Vapor Deposition empowers engineers to build superior materials from the ground up, enabling the next generation of advanced technology.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | A chemical reaction transforms gas precursors into a solid film on a heated substrate. |

| Key Feature | Non-line-of-sight, conformal coating for complex shapes. |

| Primary Advantage | Exceptional purity, density, and precise control over film properties. |

| Ideal For | High-performance electronics, protective coatings, and novel material R&D. |

Ready to engineer superior thin films for your lab's projects?

KINTEK specializes in providing the precise lab equipment and consumables needed for advanced processes like Chemical Vapor Deposition. Whether you are developing next-generation semiconductors, applying protective coatings, or conducting cutting-edge materials research, our solutions are designed to meet the demanding requirements of your laboratory.

Contact our experts today to discuss how we can support your high-value applications with reliable, high-performance technology.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is CVD method for graphene? A Scalable Process for High-Quality, Large-Area Films

- What is the difference between ALD and CVD? Precision vs. Speed in Thin Film Deposition

- How do the growth patterns of HPHT, CVD, and natural diamonds differ? Uncover the Morphology of Lab vs. Mined Gems

- How does film thickness affect adhesion? The Hidden Role of Internal Stress in Coating Failure

- What are the advantages of CVD technique over other deposition processes? Superior Conformal Coating for Complex 3D Parts

- What materials can be deposited by CVD? Unlock the Full Range from Metals to Diamond

- How expensive is DLC coating? Understand the Cost of Premium, High-Performance Finishing

- What are the main components of a Hot Filament Chemical Vapour Deposition (HFCVD) system? Master Diamond Synthesis