In freeze-drying, collapse is a critical failure event. It occurs when the product softens during the primary drying phase to the point where it can no longer support its own microscopic, porous structure. This structural failure effectively ruins the product, trapping moisture, preventing proper reconstitution, and destroying the elegant architecture that freeze-drying is designed to create.

Collapse is not a cosmetic flaw; it is a fundamental process failure. It signals that the product's temperature has exceeded its critical limit, causing irreversible damage that compromises the stability, solubility, and quality of the final product.

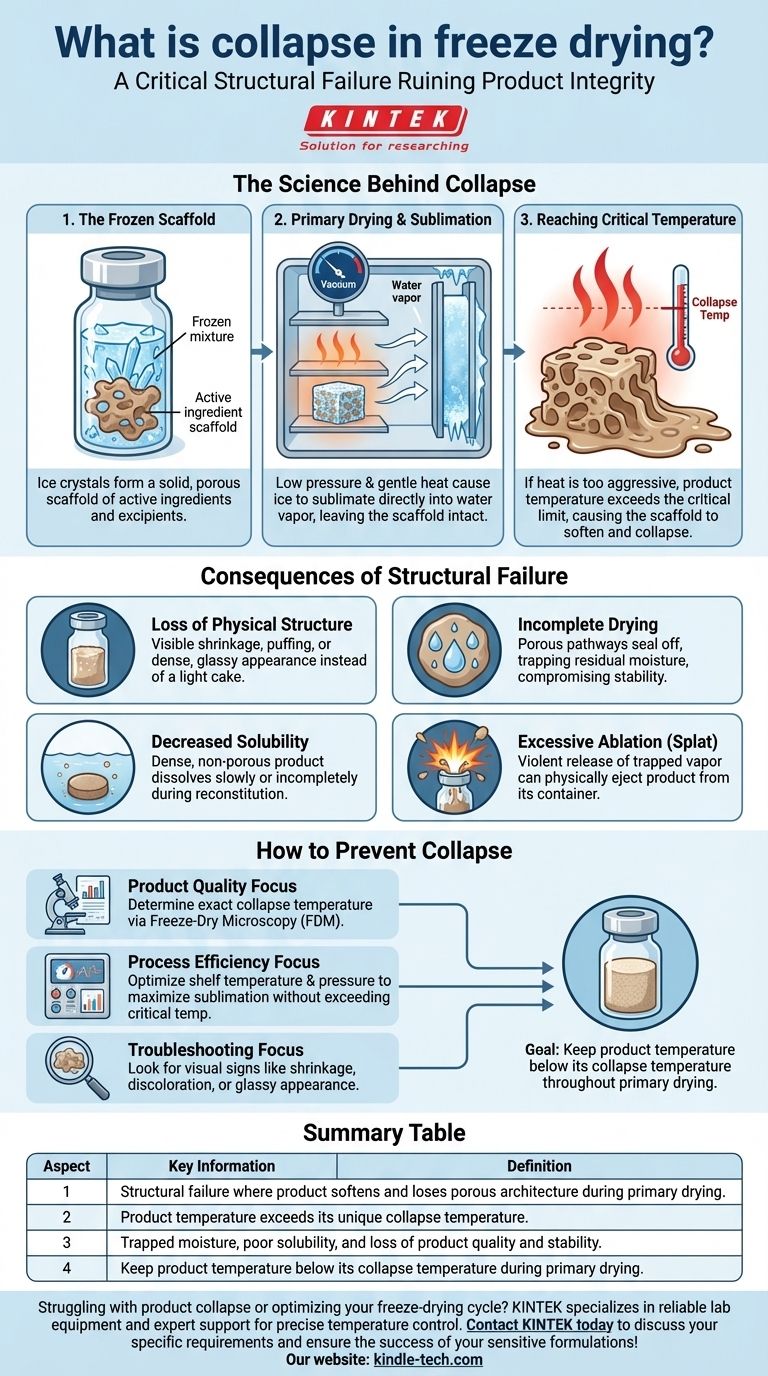

The Science Behind Freeze-Drying Collapse

To understand collapse, we must first understand the structure that is being destroyed. Freeze-drying is a process of preservation that hinges on maintaining this delicate architecture.

The Frozen "Scaffold"

When a product is frozen, the water forms a crystalline ice structure. The product's active ingredients and excipients become concentrated in the spaces between these ice crystals, forming a solid, amorphous "scaffold."

This scaffold is the foundation of the final freeze-dried cake. The goal of the process is to remove the ice while leaving this intricate structure perfectly intact.

Primary Drying and Sublimation

The primary drying phase removes the bulk of the water (around 95%). During this step, chamber pressure is lowered to a deep vacuum, and a controlled amount of heat is applied to the shelves.

This combination of low pressure and gentle heat causes the frozen water to sublimate—transforming directly from a solid (ice) into a gas (water vapor) without passing through a liquid phase. The cold condenser plates in the freeze-dryer then trap this water vapor.

Reaching the Critical Temperature

Every formulation has a specific collapse temperature, a critical threshold unique to its composition.

If the heat added during primary drying is too aggressive, the product's own temperature can rise above this critical point. When this happens, the solid scaffold softens and begins to flow like a highly viscous liquid. The structure can no longer support its own weight and simply gives way.

The Consequences of Structural Failure

A collapsed product is often unsalvageable. The damage manifests in several distinct ways, all of which stem from the loss of the porous internal structure.

Loss of Physical Structure

The most obvious sign of collapse is a visible change in the product. Instead of a light, porous cake, you will see shrinkage, puffing, or a dense, glassy substance at the bottom of the vial.

Incomplete Drying

The porous network created by sublimation acts as a pathway for water vapor to escape from deep within the product. When the structure collapses, these pathways are sealed off.

This traps residual moisture inside the product, making it impossible to dry completely and severely compromising its long-term stability.

Decreased Solubility

A key benefit of a properly freeze-dried product is its rapid and complete reconstitution. The high surface area of the porous scaffold allows liquid to penetrate and dissolve the product almost instantly.

A collapsed product, being dense and non-porous, will dissolve very slowly, incompletely, or not at all.

Excessive Ablation (Splat)

In severe cases of collapse, the violent release of trapped water vapor can physically eject the product from its container. This phenomenon, often called "splat," is a clear and dramatic indicator of a failed process.

How to Prevent Collapse in Your Process

Preventing collapse requires a disciplined approach that respects the thermal limits of your specific formulation. The entire goal is to keep the product temperature below its collapse temperature throughout primary drying.

- If your primary focus is product quality and viability: Prioritize determining the exact collapse temperature of your formulation through analytical techniques like Freeze-Dry Microscopy (FDM) before you begin cycle development.

- If your primary focus is process efficiency: Carefully optimize the shelf temperature and chamber pressure to maximize the sublimation rate without ever allowing the product temperature to exceed its known collapse temperature.

- If you are troubleshooting a failed batch: Look for visual signs like shrinkage, discoloration, or a glassy appearance, as these are clear indicators that your primary drying parameters were too aggressive for the product.

Ultimately, mastering freeze-drying means balancing the need for speed with the absolute requirement to preserve the product's foundational structure.

Summary Table:

| Aspect | Key Information |

|---|---|

| Definition | Structural failure where the product softens and loses its porous architecture during primary drying. |

| Main Cause | Product temperature exceeds its unique collapse temperature. |

| Primary Consequence | Trapped moisture, poor solubility, and loss of product quality and stability. |

| Key Prevention | Keep product temperature below its collapse temperature during primary drying. |

Struggling with product collapse or optimizing your freeze-drying cycle? KINTEK specializes in providing reliable lab equipment and expert support for all your laboratory needs. Our freeze-dryers and consumables are designed to help you achieve precise temperature control and maintain product integrity. Let our experts help you prevent failure and enhance your process efficiency. Contact KINTEK today to discuss your specific requirements and ensure the success of your sensitive formulations!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability