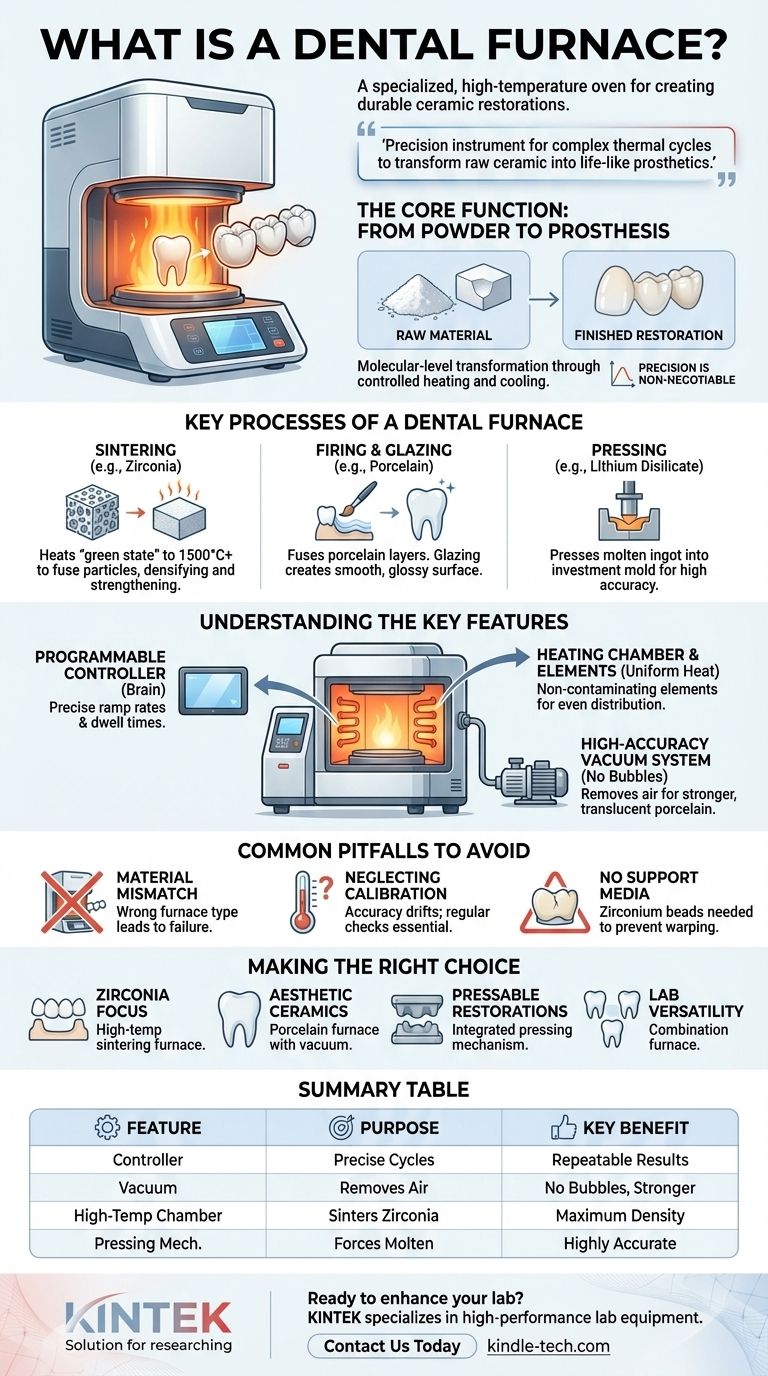

A dental furnace is a specialized, high-temperature oven used in dental laboratories to create durable and aesthetic ceramic restorations like crowns, bridges, and veneers. It operates by subjecting ceramic materials to precisely controlled heating cycles, sometimes under vacuum or pressure. This process transforms the material from a fragile, pre-processed state into its final, hardened form, ready for patient use.

A dental furnace is not merely a heat source; it is a precision instrument that executes complex, programmed thermal cycles to transform raw ceramic materials into strong, perfectly fitted, and life-like dental prosthetics.

The Core Function: From Powder to Prosthesis

A dental furnace is the critical final step in the digital or analog production of many dental restorations. It takes a milled, pressed, or hand-layered ceramic structure and converts it into a monolithic, biocompatible component through carefully managed thermal energy.

The Material Transformation

Think of a dental furnace like a highly advanced kiln. It doesn’t just bake the material; it initiates a molecular-level transformation. The controlled heating and cooling cycles are designed to fuse ceramic particles together, eliminate impurities, and achieve the desired density, strength, and optical properties like translucency.

Precision is Non-Negotiable

Every ceramic system has a unique firing schedule specified by the manufacturer. Deviating from this schedule—even by a few degrees—can lead to a failed restoration. This is why modern furnaces are digitally programmable, ensuring every cycle is repeatable and accurate.

Key Processes of a Dental Furnace

Different ceramic materials require different thermal processes. A versatile dental furnace can typically handle several of these, making it a central piece of lab equipment.

Sintering

Sintering is used for materials like zirconia. In this process, the furnace heats a porous, "green state" restoration to a very high temperature (often over 1500°C). This causes the ceramic particles to fuse, densifying the structure and shrinking it to its precise final dimensions with incredible strength.

Firing and Glazing

Firing is the classic process for building up porcelain restorations. A technician applies layers of porcelain powder mixed with a liquid, and the furnace fires each layer to fuse the particles. Glazing is a final, lower-temperature firing cycle that melts a thin outer layer, creating a smooth, glossy, and stain-resistant surface that mimics natural tooth enamel.

Pressing

Pressing is a technique for materials like lithium disilicate. A wax model of the restoration is created and encased in an investment mold. The furnace heats a ceramic ingot until it becomes molten, then a plunger "presses" the molten ceramic into the mold, creating a dense and highly accurate restoration.

Understanding the Key Features

Modern dental furnaces are defined by their ability to control the heating environment with extreme precision.

The Programmable Controller

This is the furnace's brain. Technicians can program multi-stage cycles with specific ramp rates (how fast the temperature rises or falls) and dwell times (how long a specific temperature is held). High-end models feature large touch screens for intuitive operation.

The Heating Chamber and Elements

The chamber is where the magic happens. It is lined with high-quality insulation and contains heating elements, often made of non-contaminating silicon carbide, to ensure uniform heat distribution. The chamber's capacity dictates how many restorations can be processed at once.

High-Accuracy Vacuum System

For porcelain firing, a vacuum is crucial. By removing air from the chamber during the heating cycle, the furnace prevents bubbles from forming within the porcelain. This results in a stronger, denser, and more translucent restoration.

Common Pitfalls to Avoid

While essential, a dental furnace's performance depends heavily on proper use and maintenance.

Material Mismatch

Not all furnaces can do everything. A furnace designed for porcelain typically cannot reach the high temperatures required for sintering zirconia. Using the wrong type of furnace for a material will result in a complete failure.

The Importance of Calibration

A furnace's temperature accuracy can drift over time. Regular calibration using specialized kits is essential. An uncalibrated furnace can lead to weak, ill-fitting, or poorly shaded restorations, wasting significant time and material.

Neglecting Support Media

When sintering, restorations must be placed on a specialized tray with zirconium support beads. These beads allow for even heat circulation and prevent the restoration from warping or sticking to the tray during the critical shrinkage phase.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the services a dental lab intends to offer.

- If your primary focus is Zirconia Restorations: You need a dedicated high-temperature sintering furnace capable of executing precise, multi-hour cycles.

- If your primary focus is Aesthetic Layered Ceramics: A porcelain furnace with exceptional vacuum accuracy and fine control over temperature ramps is critical.

- If your primary focus is Pressable Restorations: Your furnace must have an integrated pressing mechanism alongside its standard heating functions.

- If your lab needs versatility: Combination furnaces exist that can handle both pressing and porcelain firing, offering a space-saving solution for diverse needs.

Ultimately, the dental furnace is the device that breathes strength and life into ceramic restorations, making it an indispensable asset for any modern dental laboratory.

Summary Table:

| Feature | Purpose | Key Benefit |

|---|---|---|

| Programmable Controller | Executes precise heating/cooling cycles | Ensures repeatable, accurate results for every restoration |

| Vacuum System | Removes air during porcelain firing | Prevents bubbles, increases strength and translucency |

| High-Temp Chamber | Sinters zirconia (1500°C+) | Fuses particles for maximum density and durability |

| Pressing Mechanism | Forces molten ceramic into a mold | Creates highly accurate pressable restorations (e.g., lithium disilicate) |

Ready to enhance your lab's capabilities with a precision dental furnace?

KINTEK specializes in high-performance lab equipment for dental laboratories. Whether you focus on zirconia sintering, porcelain firing, or pressable ceramics, our furnaces deliver the accuracy, reliability, and consistency you need to produce superior restorations.

Contact us today to find the perfect dental furnace for your specific workflow and goals.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges