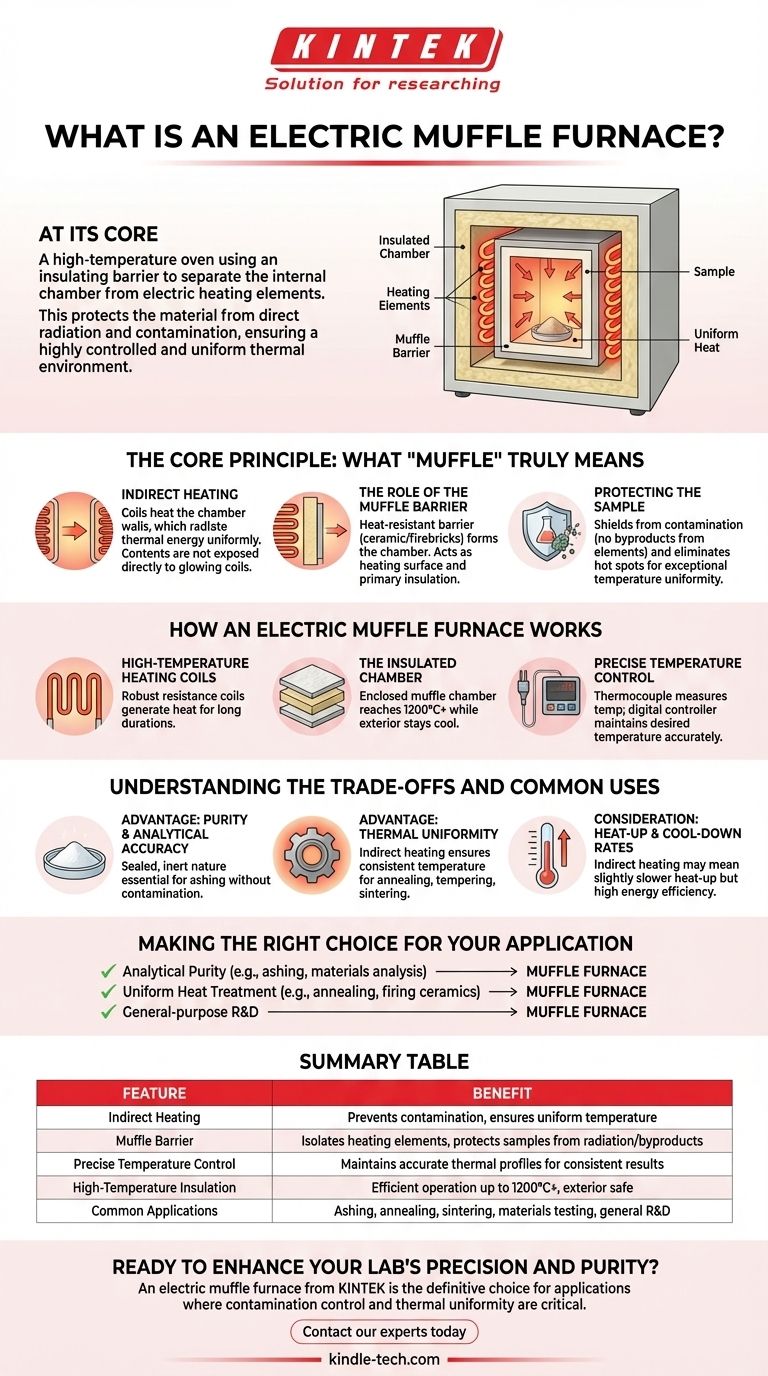

At its core, an electric muffle furnace is a high-temperature oven that uses an insulating barrier to separate the internal chamber from the electric heating elements. This fundamental design protects the material being heated from direct radiation and potential contamination, ensuring a highly controlled and uniform thermal environment. It is a standard piece of equipment in laboratories and industrial settings for processes requiring precision and purity.

The defining feature of a muffle furnace isn't just its ability to reach high temperatures, but its method of indirect heating. By isolating the sample within a "muffle," it guarantees that the heat is uniform and the sample remains uncontaminated by the heat source itself.

The Core Principle: What "Muffle" Truly Means

The term "muffle" is central to understanding how this furnace operates. It describes the physical separation between the heat source and the object being heated, a concept that defines the furnace's primary advantages.

The Concept of Indirect Heating

In a muffle furnace, the contents of the chamber are not exposed directly to the glowing-hot heating coils. Instead, the coils heat the chamber walls.

These heated walls then radiate thermal energy uniformly throughout the chamber, gently and evenly heating the sample from all sides.

The Role of the Muffle Barrier

The "muffle" itself is the heat-resistant barrier that forms the chamber. In modern electric furnaces, this is typically made of high-purity ceramic fiber or durable firebricks.

The heating elements are embedded within or placed just behind this material. The muffle acts as both the heating surface and the primary insulation, preventing heat from escaping and ensuring energy efficiency.

Protecting the Sample

This design provides two critical benefits. First, it shields the sample from contamination, as no byproducts from the heating elements can enter the chamber. This is vital for applications like ashing or chemical analysis.

Second, it eliminates hot spots caused by direct radiation, leading to exceptional temperature uniformity across the entire sample.

How an Electric Muffle Furnace Works

The operation is straightforward but highly effective, relying on a few key components working in concert to create a stable, high-temperature environment.

High-Temperature Heating Coils

The heat source consists of robust electric resistance coils designed to withstand extreme temperatures for long durations. These coils are the engine of the furnace.

The Insulated Chamber

The muffle chamber contains the sample and is enclosed by layers of insulation. This construction allows the furnace to reach temperatures of 1200°C or higher while the exterior remains relatively cool.

Precise Temperature Control

A thermocouple inside the chamber constantly measures the temperature and feeds this data to a digital controller. The controller cycles the power to the heating coils to maintain the desired temperature with a high degree of accuracy.

Understanding the Trade-offs and Common Uses

While incredibly useful, it's important to understand the characteristics that make a muffle furnace suitable for specific tasks. It is also known more generally as a chamber furnace or box furnace.

Advantage: Purity and Analytical Accuracy

The sealed, inert nature of the muffle chamber is its greatest strength. It is essential for processes like ashing materials, where the goal is to burn off organic matter without contaminating the remaining inorganic residue.

Advantage: Thermal Uniformity

For heat treatment processes like annealing, tempering, or sintering, consistent temperature is critical. The indirect heating of a muffle furnace ensures that an entire part, or batch of parts, experiences the exact same thermal profile.

Consideration: Heat-Up and Cool-Down Rates

Because the heat is transferred indirectly, muffle furnaces may have slightly slower heat-up times compared to furnaces with exposed elements. However, their excellent insulation also means they are highly energy-efficient once at temperature.

Making the Right Choice for Your Application

To determine if a muffle furnace is the correct tool, consider your primary objective.

- If your primary focus is analytical purity (e.g., ashing, materials analysis): The muffle furnace is the definitive choice to prevent sample contamination.

- If your primary focus is uniform heat treatment (e.g., annealing metals, firing ceramics): The indirect heating method provides unparalleled temperature consistency.

- If your primary focus is general-purpose R&D: The reliability, safety, and precision of a muffle furnace make it a foundational tool for any high-temperature laboratory work.

Ultimately, a muffle furnace is the standard for any high-temperature application where control, consistency, and purity are non-negotiable.

Summary Table:

| Feature | Benefit |

|---|---|

| Indirect Heating | Prevents sample contamination and ensures uniform temperature distribution |

| Muffle Barrier | Isolates heating elements, protecting samples from direct radiation and byproducts |

| Precise Temperature Control | Maintains accurate thermal profiles for consistent, repeatable results |

| High-Temperature Insulation | Enables efficient operation up to 1200°C+ while keeping exterior safe |

| Common Applications | Ashing, annealing, sintering, materials testing, and general R&D |

Ready to enhance your lab's precision and purity?

An electric muffle furnace from KINTEK is the definitive choice for applications where contamination control and thermal uniformity are critical. Whether you're performing ashing for analytical accuracy, annealing metals, or firing ceramics, our furnaces deliver the reliable, consistent performance your research demands.

Contact our experts today to find the perfect muffle furnace solution for your specific laboratory needs.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do you use the muffle furnace? Master Safe and Precise High-Temperature Processing

- What is the temperature limit on a muffle furnace? A Guide to Selecting the Right Model

- What is the inside material of the muffle furnace? Discover the Refractory Core for High-Temp Precision

- How do you handle a muffle furnace? A Step-by-Step Guide for Safe & Accurate Operation

- What is muffle furnace principle and procedure? Master Safe, Contaminant-Free High-Temperature Processing