To use a muffle furnace, you must first ensure it is properly set up and grounded on a stable surface. The core process involves turning on the power, setting the desired temperature, and allowing the furnace to pre-heat. Once stable, you place your sample inside the chamber, close the door, and run the heating cycle for the required time before turning off the power and letting the furnace cool completely before removing the sample.

The key to using a muffle furnace is understanding its purpose: to create a highly controlled and isolated thermal environment. Correct operation is not just about following steps, but about maintaining this control to ensure safety, achieve accurate results, and protect the equipment.

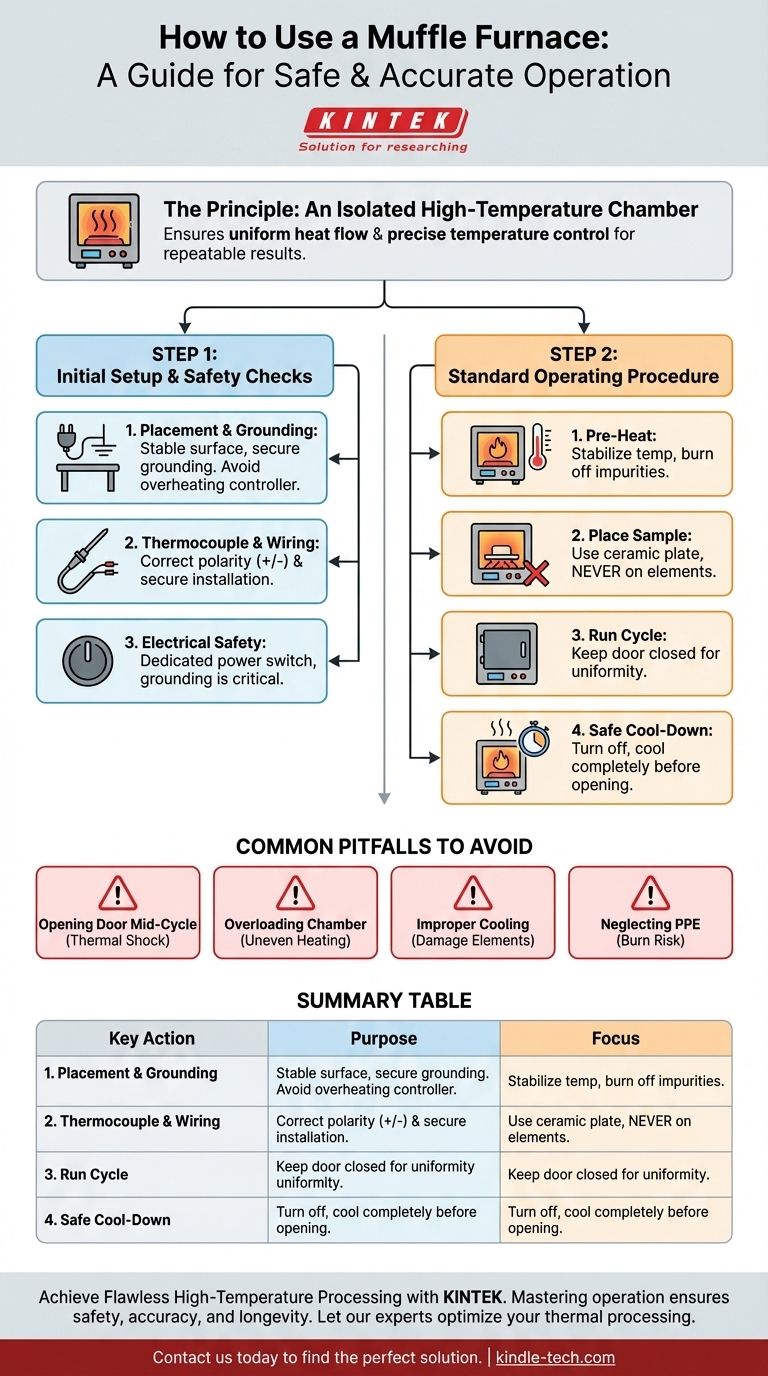

The Principle: An Isolated High-Temperature Chamber

How It Works

A muffle furnace uses electric heating elements to heat an insulated chamber to very high temperatures. The term "muffle" refers to the chamber's ability to isolate the material being heated from the heating elements and any contaminants from combustion (in fuel-fired models).

This design ensures uniform heat flow and precise temperature control, which are critical for repeatable scientific and industrial processes. The chamber is typically lined with high-quality refractory bricks or insulation to prevent heat loss and maintain efficiency.

Step 1: Initial Setup and Safety Checks

Physical Placement

Before operation, place the furnace on a flat, stable surface. Ensure the temperature controller is positioned away from the furnace body to prevent it from overheating, which can damage its sensitive electronics.

Thermocouple and Wiring

The thermocouple is the sensor that measures the internal temperature. Insert it into the furnace chamber through its designated port, filling any gaps with asbestos rope to prevent heat leakage. Connect it to the controller, paying close attention to the correct polarity (+ and -).

Electrical Safety

Always install a dedicated power switch at the main power line inlet for the furnace. Crucially, both the furnace and the controller must be securely grounded to prevent electrical shock. Only personnel authorized by management should operate the furnace.

Step 2: The Standard Operating Procedure

Pre-Heating and Conditioning

Turn on the power and set your target temperature. After the first use or long periods of inactivity, it is best practice to run the furnace empty for a period. This "baking" process helps stabilize the internal environment and burns off any residual impurities.

The furnace's indicator lights will show its status. Typically, a green light indicates the temperature is rising, while a red light signifies it has reached and is maintaining the set temperature.

Placing Your Sample

Wait for the furnace to reach and stabilize at the set temperature. Carefully place your samples into the chamber, ensuring they are stable and will not tip over during the process.

Never place samples directly on the heating elements or the furnace floor if it contains elements. This can cause severe damage and create a fire risk. Use a ceramic plate or appropriate crucible.

Running the Heating Cycle

Close the furnace door securely during heating. This is essential to prevent heat loss, maintain temperature uniformity, and stop cold air from entering, which could thermally shock your sample or the furnace chamber. Monitor the temperature throughout the process to ensure it remains stable.

Safe Shutdown and Cooling

After the required heating time has elapsed, turn off the furnace power. Do not open the door immediately. Allow the furnace to cool down naturally to a safe temperature before carefully removing your samples using appropriate heat-resistant gloves and tongs.

Common Pitfalls to Avoid

Opening the Door Mid-Cycle

Resist the urge to check on your sample by opening the door. The sudden influx of cold air can crack the furnace's insulation or your sample, a phenomenon known as thermal shock.

Overloading the Chamber

Placing too many samples in the furnace can obstruct airflow and lead to non-uniform heating. This compromises the accuracy and consistency of your results.

Improper Cooling

Forcing the furnace to cool too quickly can damage the internal refractory materials and heating elements, shortening the equipment's lifespan. Always allow for a slow, natural cool-down period.

Neglecting Safety Gear

The exterior of a furnace can remain extremely hot long after it has been turned off. Always assume it is hot and use appropriate personal protective equipment (PPE), including heat-resistant gloves and safety glasses.

Key Principles for Successful Operation

- If your primary focus is accuracy and repeatability: Always pre-heat the furnace and allow the temperature to stabilize before introducing your sample, ensuring consistent and uniform results every time.

- If your primary focus is operator and equipment safety: Never bypass safety features like grounding, and always allow the furnace to cool completely before removing your materials to prevent burns and thermal shock.

- If your primary focus is maximizing equipment lifespan: Avoid placing samples directly on heating elements and never introduce cold items into a hot furnace, as this prevents costly damage to core components.

By mastering these operational principles, you ensure not only the safety of your workspace but also the integrity and reliability of your results.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Setup | Ensure stable placement, secure grounding, and correct thermocouple installation. | Foundation for safety and accurate temperature control. |

| 2. Operation | Pre-heat to stabilize, place sample correctly, run cycle with door closed. | Achieve uniform heating and prevent thermal shock. |

| 3. Shutdown | Turn off power and allow furnace to cool completely before opening. | Protect samples, equipment, and ensure operator safety. |

Achieve Flawless High-Temperature Processing with KINTEK

Mastering muffle furnace operation is crucial for the integrity of your laboratory work. Whether you are conducting ashing, heat treatment, or material sintering, proper technique ensures safety, accuracy, and equipment longevity.

KINTEK specializes in providing reliable lab equipment and consumables tailored to your laboratory's specific needs. Our expertise ensures you have the right tools and support for successful, repeatable results.

Let our experts help you optimize your thermal processing. Contact us today via our form to discuss your application and find the perfect solution for your lab.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does a high-temperature muffle furnace play in BZCY72 densification? Master Precision Sintering at 1500°C

- Why is a programmable high-temperature furnace required for Silicalite-1 calcination at 0.2°C/min?

- What is the function of a high-temperature convection oven for TiO2? Achieve Precise Rutile Phase Crystallization

- What critical physical effect does the sintering furnace provide? Unlocking Pre-Stress in Composite Ceramic Tubes

- What is the muffle furnace analysis? Achieve Pure, High-Temperature Processing for Your Materials

- What is the temperature of a high temperature furnace? A Guide to Selecting the Right Heat for Your Application

- What function does a constant temperature blast drying oven serve in the magnesite flotation test? Ensure Sample Integrity

- Is ash normally used to determine mineral content in foods? The Standard Method for Total Mineral Analysis