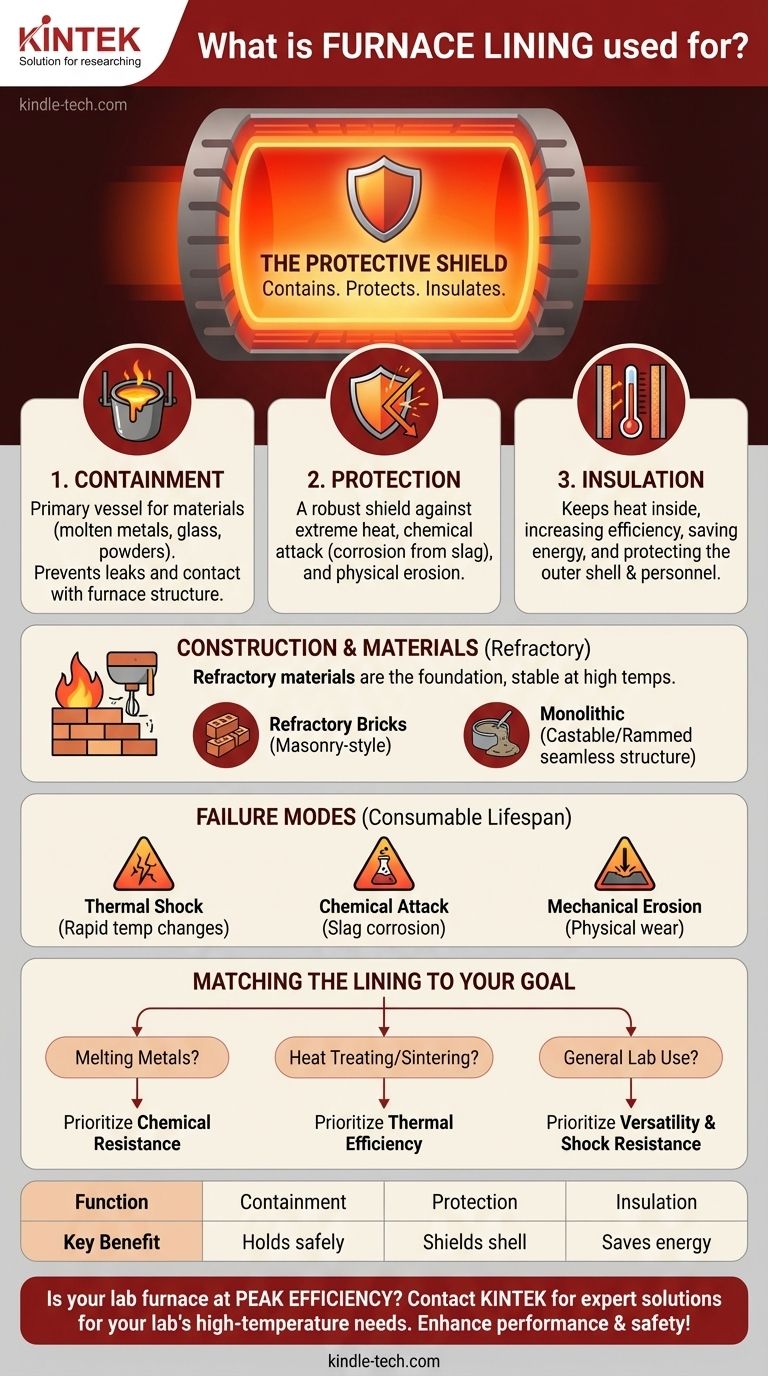

At its core, a furnace lining is a protective shield. It is a layer of heat-resistant material that performs three essential functions: containing the materials being processed, protecting the furnace's structural shell from damage, and insulating the system to maintain high temperatures efficiently and safely. Without it, a high-temperature furnace could not operate.

The furnace lining is the critical, sacrificial barrier that allows a furnace to function. It is intentionally designed to withstand extreme conditions—heat, chemical attack, and physical erosion—so that the much more expensive and complex furnace structure does not have to.

The Core Functions of a Furnace Lining

A furnace lining is not merely a passive layer; it is an active system component responsible for containment, protection, and thermal management. Its performance dictates the furnace's efficiency, safety, and operational lifespan.

Containment of Process Materials

The most fundamental job of the lining is to act as the primary vessel. It directly holds the materials being heated, which can range from molten metals and glass to powders and solid ceramics.

This function prevents the processed material from leaking or coming into contact with sensitive structural or electrical components, such as an induction furnace's copper coil.

Protection Against Extreme Conditions

Furnaces operate at temperatures that can easily melt their own steel shells. The lining serves as a robust shield against several forms of attack.

It provides thermal protection by withstanding extreme heat and rapid temperature changes. It also offers chemical protection, resisting corrosion from byproducts like molten slag, and physical protection against erosion caused by the movement of materials inside the furnace.

Thermal Insulation and Efficiency

A lining's ability to keep heat contained within the furnace is crucial for performance. This insulation ensures that energy is used to heat the material, not lost to the surrounding environment.

Effective insulation lowers energy costs, allows for more precise temperature control, and protects the outer furnace body and nearby personnel from extreme heat.

How Furnace Linings Are Constructed

The term "lining" can refer to several different forms and materials, each chosen based on the furnace's specific application and design. The material used is always a refractory, meaning it is physically and chemically stable at high temperatures.

The Role of Refractory Materials

Refractory materials are the foundation of any lining. They can be pre-formed shapes like refractory bricks, which are mortared together in a masonry-style construction.

They can also be monolithic, meaning they are installed as a single, seamless structure. This is done using castable cements, plastic ramming mixes, or dry powders that are compacted and sintered in place.

Common Installation Methods

The method of installing a lining depends on the furnace's size and type.

- Masonry: Brick-by-brick construction is common in large, continuously operated furnaces.

- In-Furnace Forming: Monolithic materials are often packed or rammed directly inside the furnace shell, either manually or with machinery.

- Out-of-Furnace Molding: For some smaller furnaces, the lining can be formed in a mold, pre-fired for strength, and then inserted into the furnace.

Understanding the Trade-offs: Why Linings Fail

A furnace lining is a consumable component with a finite lifespan. Understanding its failure modes is critical for safe and efficient furnace operation, as lining failure can be catastrophic.

Thermal Shock

Rapid changes in temperature are a primary enemy of refractory linings. Heating up or cooling down too quickly can cause cracks to form, compromising the lining's structural integrity and protective function.

Chemical Attack

The materials being processed, especially in metallurgy, can create aggressive byproducts like slag. This slag can chemically react with the refractory material, corroding it and "eating away" at the lining over time.

Mechanical Erosion

The physical movement of molten metal, the charging of new material, or even the flow of hot gases can physically wear down the lining surface. This erosion slowly thins the protective layer, eventually requiring repair or replacement.

Matching the Lining to Your Goal

The right lining depends entirely on the furnace's purpose. The choice of material and construction method involves balancing durability, cost, and thermal performance for the specific industrial process.

- If your primary focus is melting metals: You need a lining with superior resistance to chemical attack from slag and excellent containment of high-temperature liquids.

- If your primary focus is heat treating or sintering ceramics: You need a lining that ensures thermal efficiency, provides uniform heat, and prevents any chemical contamination of the finished parts.

- If your primary focus is general laboratory use: You need a versatile lining that can withstand the thermal shock of frequent heating and cooling cycles across different experiments.

Ultimately, the furnace lining is not just an accessory; it is the essential enabling component that makes high-temperature industrial processes both possible and safe.

Summary Table:

| Function | Key Benefit |

|---|---|

| Containment | Holds process materials safely inside the furnace. |

| Protection | Shields the furnace shell from heat, chemicals, and erosion. |

| Insulation | Maintains high temperatures efficiently, saving energy. |

Is your lab furnace operating at peak efficiency and safety? The right furnace lining is critical for protecting your equipment and ensuring consistent results. KINTEK specializes in lab equipment and consumables, providing expert solutions for your laboratory's high-temperature needs. Let our specialists help you select the ideal lining material for your specific application—from metal melting to ceramic sintering. Contact us today for a consultation and enhance your lab's performance and safety!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a laboratory orbital shaker in copper recovery? Optimize Industrial Waste Liquid Processing

- Why are zirconia grinding jars and balls required for sulfide electrolytes? Ensure Purity in Na3SbS4 & Na3PS4 Synthesis

- What can I use a vacuum pump for? Powering Industrial Processes from Packaging to Automation

- How should one select a rotary vane vacuum pump based on the intended application? Expert Guide to Optimal Selection

- What monitoring function do graphite rams perform during vacuum hot pressing? Optimize Eu:Y2O3 Ceramic Densification

- Which type of refractory lining is used in a glass tank furnace? AZS Refractories for Superior Glass Quality

- How does a high-precision platinum-rhodium thermocouple contribute to calculating activation energy? | KINTEK

- What is the purpose of using a zirconia mortar for small-scale mixing of NMC622 and LLZ materials? Ensure Pure Samples