In simple terms, a hydraulic jack is a device that uses a liquid, typically oil, to multiply force and lift extremely heavy objects with minimal human effort. It operates on a fundamental principle of fluid dynamics known as Pascal's Law. By applying a small force to a small piston, you generate pressure throughout the confined fluid, which then acts on a much larger piston to produce a powerful lifting force.

The critical concept to grasp is not the tool itself, but the principle of force multiplication it exploits. A hydraulic jack is a practical application of Pascal's Law, which dictates that pressure applied to an enclosed fluid is transmitted undiminished, allowing a small input force to generate a massive output force.

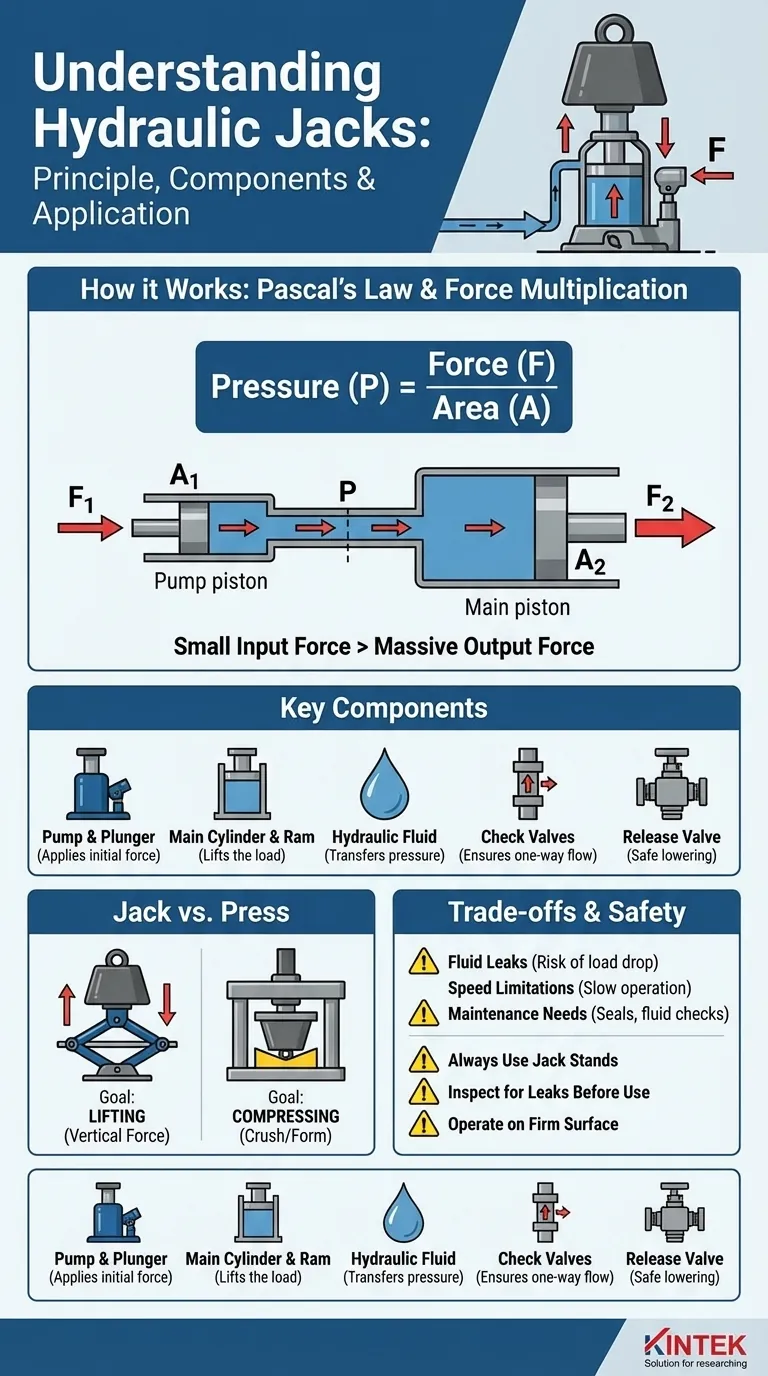

How a Hydraulic Jack Multiplies Force

To understand how a hydraulic jack turns a simple pump of a handle into a force capable of lifting a car, you must understand the physics at play.

The Foundation: Pascal's Law

The entire system is built on Pascal's Law. This principle states that when pressure is applied to a fluid in a sealed container, that pressure is distributed equally throughout the entire fluid.

Think of it like squeezing a water balloon. The pressure you apply with your fingers is felt everywhere inside the balloon, not just where you are squeezing.

The Two-Cylinder System

A hydraulic jack consists of two connected, sealed cylinders, each with a piston, but of very different sizes.

- The small cylinder has a pump piston (or plunger). This is where you apply the initial, small force (e.g., by pumping the jack handle).

- The large cylinder has a main piston (or ram). This is the piston that rises to lift the load.

The Physics of Force Multiplication

When you push down on the small pump piston, you create pressure in the hydraulic fluid. According to Pascal's Law, this exact same pressure is transmitted to the large main piston.

Because the main piston has a much larger surface area, the same pressure results in a proportionally larger force. If the main piston has 100 times the area of the pump piston, the output force will be 100 times greater than the force you applied.

Key Components of a Hydraulic Jack

While the principle is simple, several components work together to make the jack a functional tool.

Pump and Plunger

This is the mechanism where the user applies force. Pumping the handle drives a small plunger into the fluid, creating the initial pressure.

Main Cylinder and Ram

This is the workhorse of the jack. It's a large-diameter cylinder containing the main piston, or ram, which extends upward under hydraulic pressure to lift the load.

Hydraulic Fluid

This is almost always an incompressible oil. Its job is to transfer pressure efficiently from the small plunger to the large ram without being compressed itself.

Check Valves

This is what makes continuous lifting possible. A set of one-way check valves ensures fluid can be drawn into the pump and then forced into the main cylinder, but prevents it from flowing backward. This allows you to build pressure with each pump.

Release Valve

To lower the jack, you open a release valve. This allows the high-pressure fluid from the main cylinder to flow back into a reservoir, letting the ram retract smoothly under the weight of the load.

Hydraulic Jack vs. Hydraulic Press: A Crucial Distinction

While they both use the same hydraulic principles, their purpose and construction are fundamentally different. The reference materials you provided focus on hydraulic presses, so it is vital to understand the difference.

The Goal of a Jack: Lifting

A hydraulic jack is designed for one primary purpose: lifting. Its force is applied vertically upwards to overcome gravity and raise an object. They are often portable and designed to hold a load temporarily.

The Goal of a Press: Compressing

A hydraulic press is designed to compress, crush, or form an object placed within it. It uses a strong frame to contain immense forces, pressing an object between the ram and a stationary bolster plate.

The Structural Difference

A jack is typically a compact, self-contained unit. A press is a large, stationary machine built around a heavy frame that is essential for withstanding the immense compressive forces it generates.

Understanding the Trade-offs and Limitations

Hydraulic power is effective, but it comes with inherent trade-offs that are critical to understand for safe and effective use.

Risk of Fluid Leaks

The entire system relies on perfectly sealed cylinders. A failed seal can cause a sudden and complete loss of pressure, resulting in the load dropping without warning. This is the single most significant safety risk.

Speed Limitations

Hydraulic systems are powerful, but they are not fast. Lifting a heavy object requires many strokes of the pump handle, and the ram extends slowly.

Maintenance Requirements

The hydraulic fluid must be kept at the correct level and be free of contaminants. The seals and valves can wear out over time and require inspection and potential replacement to ensure safe operation.

How to Apply This Knowledge Safely

Understanding the mechanics of a hydraulic jack is the first step to using one correctly and safely. Your primary goal should always be to prevent failure.

- If your primary focus is safety: Always use secondary supports like jack stands after lifting a load; never work under a vehicle or object supported only by a hydraulic jack.

- If your primary focus is proper use: Ensure your jack is rated for a weight greater than the load you intend to lift and always operate it on a firm, level surface.

- If your primary focus is longevity: Before each use, perform a quick visual inspection for any signs of hydraulic fluid leaks around the ram or seals.

By understanding these core principles, you can use hydraulic tools not just effectively, but with the safety and confidence they demand.

Summary Table:

| Component | Function |

|---|---|

| Pump & Plunger | Applies initial force to create hydraulic pressure |

| Main Cylinder & Ram | Lifts the load using multiplied force |

| Hydraulic Fluid | Transfers pressure efficiently through the system |

| Check Valves | Allow fluid to flow in one direction for pressure buildup |

| Release Valve | Safely lowers the load by releasing fluid pressure |

Need reliable lab equipment for your research or industrial applications? KINTEK specializes in high-performance lab equipment and consumables, ensuring precision and durability for all your laboratory needs. Whether you require hydraulic systems or other specialized tools, our expertise can enhance your operational efficiency and safety. Contact us today to find the perfect solution for your laboratory!

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- Why is precise pressure control necessary for LATP densification? Optimize Density Without Cracking Your Material

- What precautions should be taken during hydraulic press? Essential Safety Guide for Operators

- What is the mechanism by which a laboratory hydraulic press facilitates the sintering of TiB2-SiC? Optimize Density

- What is uniaxial pressing of ceramics? A Guide to High-Volume Production of Simple Shapes

- What role does a large hydraulic press play in the cold working process of TT 690 alloy? Precision SCC Research Support

- What is the function of a laboratory hydraulic pressing device in U-bend SCC tests? Master Stress Corrosion Cracking

- What is the effect of pressure on hydraulic fluid? Unlock the Hidden Impact on System Performance

- What is the role of a laboratory hydraulic press in ceramic green body preparation? Ensure Data Accuracy in Expansion.