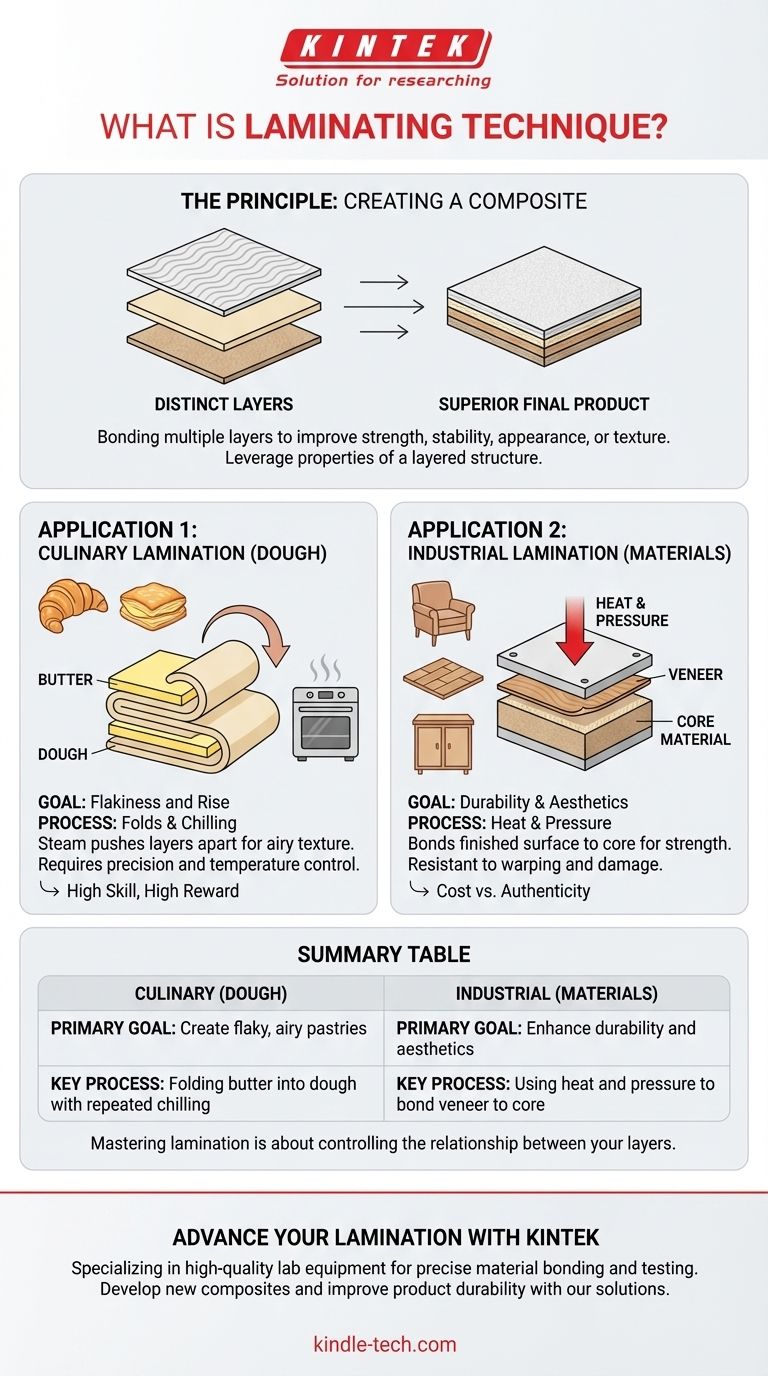

In simple terms, lamination is the technique of manufacturing a material in multiple layers. This process creates a composite material where the final product achieves improved strength, stability, appearance, or texture that the individual layers could not achieve on their own. The technique is applied in fields as different as baking, where it creates flaky pastries, and manufacturing, where it produces durable furniture surfaces.

The core principle of lamination is always the same: bonding distinct layers together to create a superior final product. Whether folding butter into dough or pressing wood veneer onto a core, the goal is to leverage the properties of a layered structure.

The Principle of Lamination: Creating a Composite

The Goal is a New Material

Lamination is not just about stacking things. It is about creating a new, composite material through the fusion of different layers.

The resulting material gains benefits from each component layer. For example, a decorative but fragile top layer can be bonded to a strong but plain core, creating a final product that is both beautiful and durable.

The Power of Layers

The magic of lamination lies in the interfaces between the layers. In pastry, these layers create separation and flakiness. In manufacturing, they provide a surface for powerful adhesives to bond materials permanently.

The process almost always involves pressure, and often heat or a binding agent (like butter in dough or glue in wood), to ensure the layers act as a single, cohesive unit.

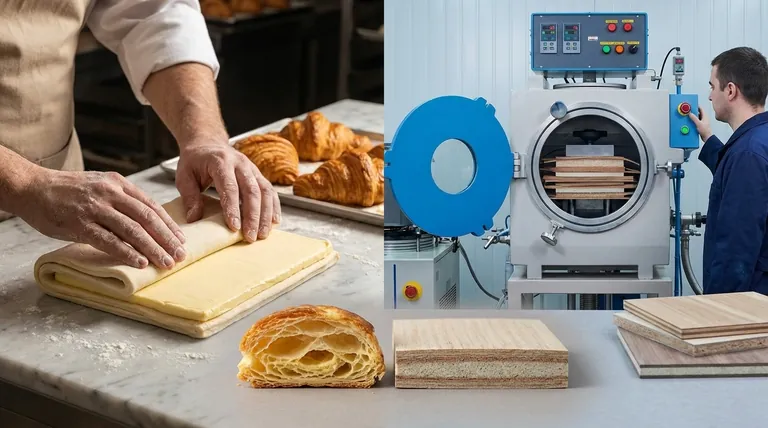

Application 1: Culinary Lamination (Dough)

The Goal: Flakiness and Rise

In baking, lamination is the process responsible for the airy, flaky layers in croissants, puff pastry, and danishes. The goal is to create dozens of ultra-thin alternating layers of dough and butter.

When baked, the water in the butter turns to steam. This steam pushes the dough layers apart, creating the signature puffy and delicate texture.

The Process: Folds and Chilling

The technique involves enclosing a slab of cold, pliable butter within a lean dough. This package is then carefully rolled out and folded over on itself multiple times.

Between each "turn" or fold, the dough is chilled rigorously. This is critical to ensure the butter remains a distinct, solid layer and doesn't simply melt into the dough, which would ruin the effect.

Application 2: Industrial Lamination (Materials)

The Goal: Durability and Aesthetics

In manufacturing, lamination is used to apply a finished surface layer to a core material. This is common in furniture, flooring, and cabinetry.

The primary goals are to improve appearance by adding a wood grain or color veneer, and to enhance durability by adding a protective, scratch-resistant outer layer to a core like particleboard or MDF.

The Process: Heat and Pressure

Industrial lamination typically uses large hot-press machines. These machines apply immense pressure and heat to bond layers together with a powerful adhesive.

This process creates a permanent, stable bond that makes the final panel or door resistant to warping and surface damage.

Understanding the Trade-offs

Culinary: High Skill, High Reward

Laminating dough is a time-consuming and technically demanding process. Success requires precision, patience, and strict temperature control.

If the butter gets too warm and melts, or gets too cold and shatters, the layers will be compromised, resulting in a greasy or dense pastry instead of a light, flaky one.

Industrial: Cost vs. Authenticity

Laminating materials allows manufacturers to produce strong, attractive products at a lower cost than using solid hardwood. It is an efficient and versatile method.

The primary trade-off is the potential for delamination (peeling) over time if the bonding is poor. Furthermore, laminated products lack the authentic feel and repairability of solid materials.

How to Apply This Knowledge

Understanding the context is key to understanding the technique.

- If your primary focus is creating flaky pastries: Your lamination technique involves precisely folding cold butter into dough with repeated chills to create separation.

- If your primary focus is producing durable, decorative surfaces: Your lamination technique uses industrial heat and pressure to permanently bond a veneer to a core material.

Ultimately, mastering lamination in any field comes from controlling the relationship between your layers.

Summary Table:

| Application | Primary Goal | Key Process |

|---|---|---|

| Culinary (Dough) | Create flaky, airy pastries | Folding butter into dough with repeated chilling |

| Industrial (Materials) | Enhance durability and aesthetics | Using heat and pressure to bond veneer to core |

Ready to enhance your lab or production process with advanced lamination techniques? KINTEK specializes in high-quality lab equipment and consumables, providing the tools you need for precise material bonding and testing. Whether you're developing new composite materials or improving product durability, our solutions are designed to meet your laboratory's unique needs. Contact us today to discover how we can support your projects with reliable, cutting-edge equipment!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Warm Isostatic Press for Solid State Battery Research

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What critical role does a Hot Press play in TlBr semiconductor crystal development? Master Precision Densification

- What is the mechanism of the pressure control system in a hydraulic press during the hot press sintering of MPCF/Al?

- Why is precise pressure control via a hydraulic system necessary during hot pressing? Optimize Nanocopper Performance

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What are the specifications and features of the platens in a hot press? Optimize Your Panel Production Efficiency

- What are the advantages of using a hot press over a cold press for LiMOCl4 composite cathodes? Boost Battery Efficiency

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing