In a laboratory, a muffle furnace is used for a wide range of high-temperature processes that require thermally transforming a sample in a controlled and isolated environment. Its primary functions include analytical processes like ashing materials to determine non-combustible content, heat-treating metals to alter their properties, and synthesizing materials like ceramics that require extreme heat to form.

The core purpose of a muffle furnace is to heat a sample to very high temperatures (typically up to 1200°C or higher) while keeping it physically separated from the heating elements. This indirect heating prevents contamination and ensures a clean, uniform thermal environment.

The Core Principle: Indirect High-Temperature Heating

To understand the furnace's applications, you must first understand its design. The name "muffle" refers to the inner chamber that encloses the sample and separates it from the actual heating coils.

How it Works

A muffle furnace is essentially a high-temperature oven. Electrical heating elements rapidly heat the space around a thermally insulating, enclosed chamber—the muffle.

The heat radiates into this muffle, raising the internal temperature to the desired setpoint without any direct contact between the sample and the heating source.

Preventing Contamination

This separation is the furnace's key advantage. Because the sample never touches a flame or electrical coil, it remains pure.

This is critical for applications like ashing, where the goal is to precisely measure the inorganic residue left after combustion, or for materials synthesis, where impurities could ruin the final product.

Achieving Extreme Temperatures

Standard laboratory ovens typically top out around 300°C. Muffle furnaces are designed with advanced insulation and durable heating elements to reliably and safely reach temperatures of 1100°C to 1200°C, with specialized models going even higher.

This capability is essential for melting glass, sintering ceramics, and performing high-temperature heat treatments on metals.

Key Laboratory Applications Explained

The furnace's design makes it indispensable for several distinct categories of laboratory work. Each application leverages the core benefits of high heat and a non-contaminating environment.

Material Analysis and Decomposition

This involves breaking a sample down to measure its components.

The most common use is ashing or loss-on-ignition analysis. A sample is heated until all organic matter burns away, allowing for the precise measurement of the non-combustible and non-volatile ash content. This is fundamental in fields like environmental science, food science, and quality control.

Materials Science and Synthesis

This involves creating new materials or changing their structure.

Sintering and calcination are common processes where powdered materials (like ceramics or metals) are heated to just below their melting point. This causes the particles to bond, creating a solid, hardened object. It is also used for creating technical ceramics, enamel coatings, and special alloys.

Heat Treatment of Metals

This involves modifying the physical properties of a metal without melting it.

Processes like annealing (softening), hardening (strengthening), and tempering (reducing brittleness) require precise temperature control to alter the metal's internal crystal structure. The muffle furnace provides the stable, high-heat environment needed for these transformations.

High-Temperature Sample Preparation

In many analytical workflows, a sample must be processed before it can be measured by another instrument.

A muffle furnace is used for the pretreatment of medical or environmental samples to remove organic interference. It is also used for alkali fusion, a process where an otherwise insoluble sample is mixed with a flux and heated until it melts, rendering it soluble for further chemical analysis.

Understanding the Trade-offs

While powerful, a muffle furnace is not the right tool for every thermal application. Understanding its limitations is key to using it effectively.

Not for Controlled Atmospheres (By Default)

A standard muffle furnace operates in ambient air. If your process requires an inert atmosphere (like nitrogen or argon) or a reactive one, you will need a specialized tube furnace, not a conventional muffle furnace.

Slower Heating and Cooling Cycles

The heavy insulation required to reach and maintain extreme temperatures means these furnaces do not heat up or cool down quickly. They are best suited for batch processes, not for applications that demand rapid temperature changes.

Potential for Thermal Gradients

While generally providing uniform heat, the temperature can vary slightly in different parts of the chamber. For highly sensitive processes, careful sample placement and furnace calibration are essential to ensure consistent results.

Making the Right Choice for Your Goal

The decision to use a muffle furnace should be based directly on your material and desired outcome.

- If your primary focus is quantitative analysis (like ashing): The furnace's ability to cleanly and completely combust organic material to isolate inorganic residue is its key advantage.

- If your primary focus is materials synthesis (like creating ceramics): The furnace provides the stable, extreme temperatures necessary to induce the physical and chemical changes that form new materials.

- If your primary focus is modifying metal properties (like annealing): The controlled, high-heat environment is essential for precisely altering a metal's internal microstructure and physical characteristics.

Ultimately, the muffle furnace is an indispensable laboratory instrument for any work that demands clean, reliable, and extreme heat.

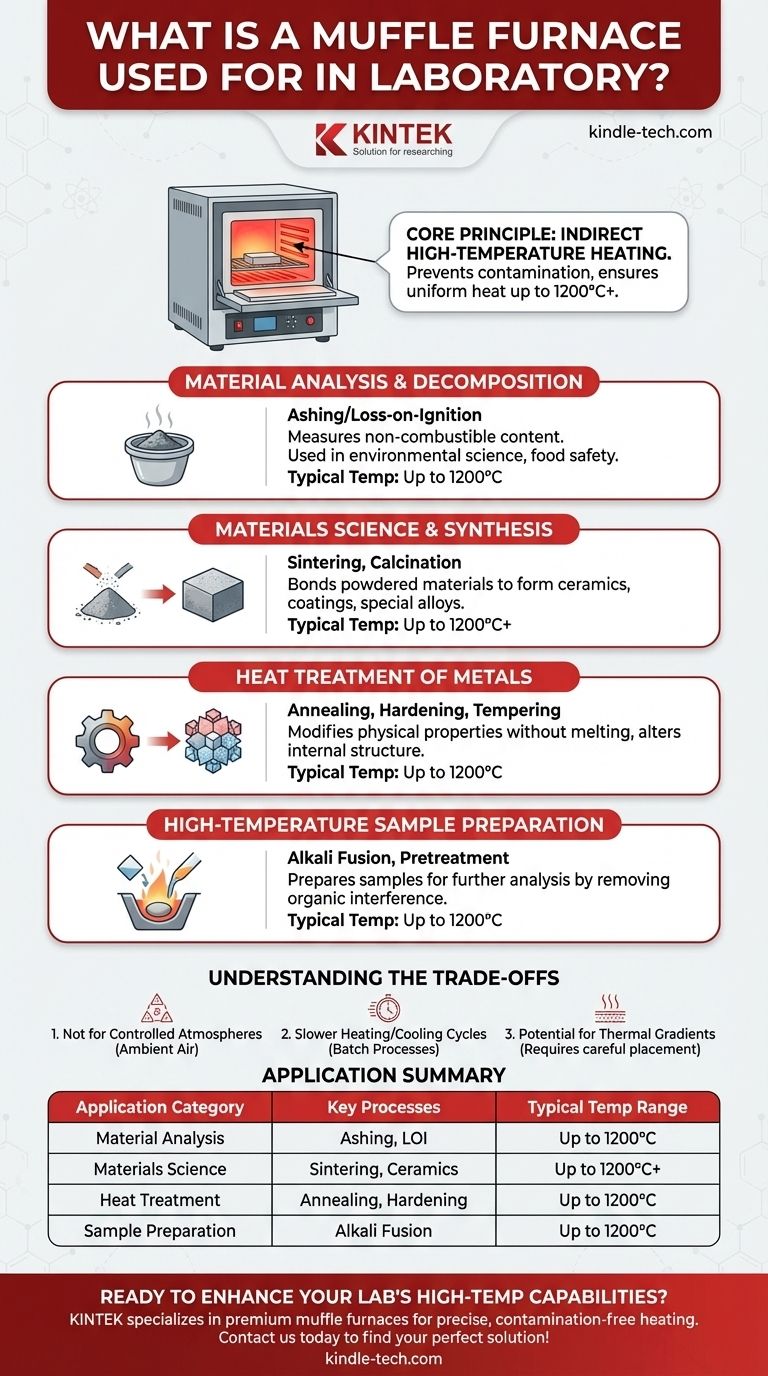

Summary Table:

| Application Category | Key Processes | Typical Temperature Range |

|---|---|---|

| Material Analysis | Ashing, Loss-on-Ignition | Up to 1200°C |

| Materials Science | Sintering, Calcination, Ceramics Synthesis | Up to 1200°C+ |

| Heat Treatment | Annealing, Hardening, Tempering | Up to 1200°C |

| Sample Preparation | Alkali Fusion, Pretreatment | Up to 1200°C |

Ready to enhance your lab's high-temperature capabilities? KINTEK specializes in premium laboratory equipment, including muffle furnaces designed for precise, contamination-free heating up to 1200°C and beyond. Whether you're in materials science, quality control, or research, our solutions ensure reliable performance for ashing, sintering, heat treatment, and more.

Contact us today to find the perfect furnace for your specific application and achieve superior results with KINTEK's trusted lab technology.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the uses of muffle furnaces? Achieve Precise, Contamination-Free High-Temperature Processing

- What is the use of muffle furnace in food laboratory? Essential for Accurate Nutritional Analysis & Quality Control

- What is the difference between oven incubator and muffle furnace? Choose the Right Lab Heating Tool

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- How do you take care of a muffle furnace? Extend Equipment Life and Ensure Accurate Results