In its simplest terms, press molding is a ceramic forming technique where clay or another ceramic material is forced into a mold to create a specific shape. This process utilizes pressure to ensure the material conforms precisely to the mold's internal cavity, resulting in a positive, or direct copy, of the mold's design.

The true value of modern press molding, particularly heat-pressing, lies in its ability to produce highly dense, incredibly accurate ceramic components. It is a process that prioritizes precision and material integrity above all else.

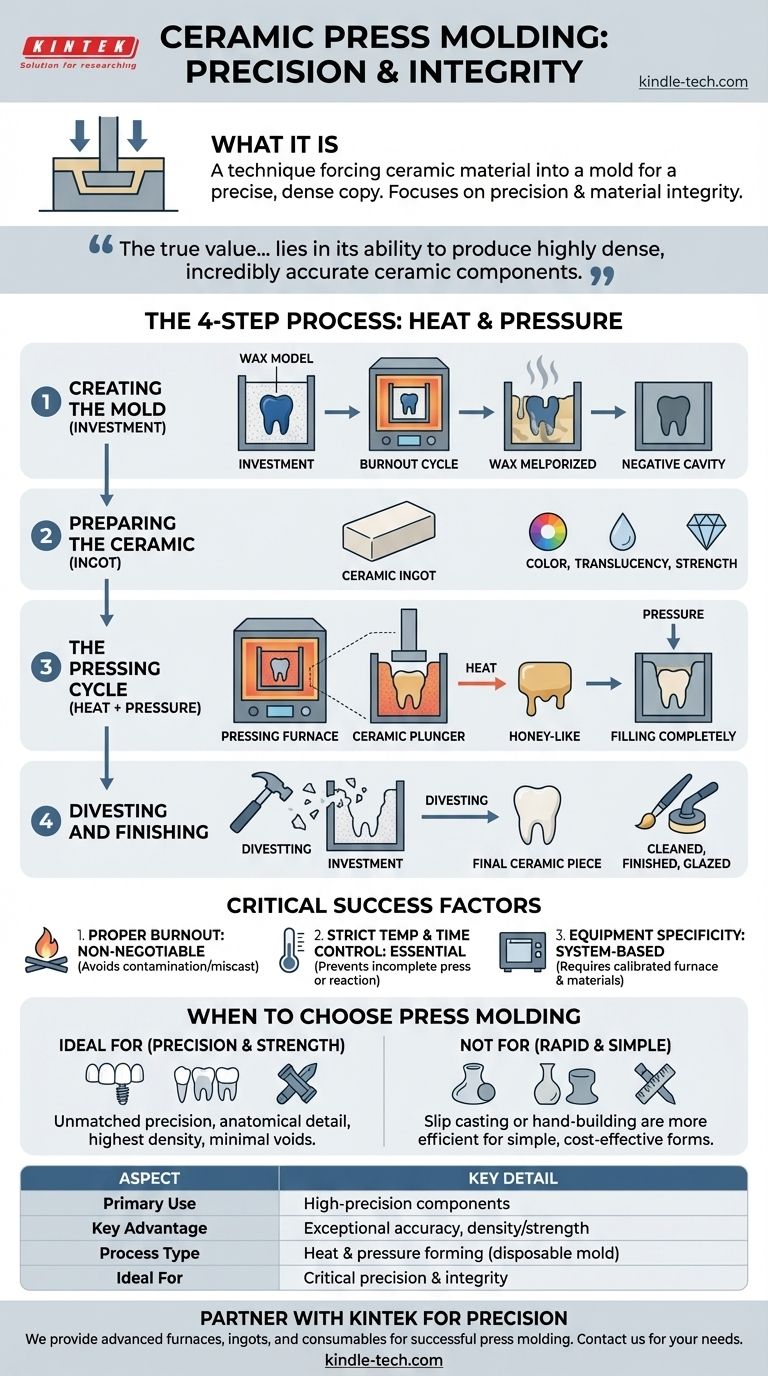

Deconstructing the Press Molding Process

While simple pressing of wet clay exists, the most common professional application, especially in fields like dental technology, is a more sophisticated heat-press process. This method involves transforming a solid ceramic ingot into a final shape using heat and pressure.

Step 1: Creating the Mold (The Investment)

The process begins not with a reusable mold, but by creating a disposable one. A model of the desired object is first made, typically out of wax.

This wax pattern is then encased in a heat-resistant plaster-like material called an investment. Once the investment hardens, it is placed in a furnace for a burnout cycle.

The burnout cycle serves two purposes: it completely melts and vaporizes the wax, leaving a precisely detailed negative cavity, and it pre-heats the mold to the correct temperature for pressing.

Step 2: Preparing the Ceramic (The Ingot)

The raw material for pressing is a pre-fabricated, standardized block of ceramic known as an ingot.

These ingots are manufactured under industrial conditions to have specific properties, such as color, translucency, and strength. The appropriate ingot is selected based on the requirements of the final piece.

Step 3: The Pressing Cycle (Heat and Pressure)

The heated investment mold is placed into a specialized pressing furnace. The ceramic ingot and a ceramic plunger are placed into a channel leading to the mold cavity.

The furnace heats the ingot until it softens to a viscous, honey-like consistency. At the precise moment, the plunger applies pressure, forcing the softened ceramic to flow into and completely fill the negative space left by the burned-out wax.

Step 4: Divesting and Finishing

After the pressing cycle is complete and the mold has cooled, the investment material is carefully broken away, or "divested," revealing the final ceramic piece.

This piece is a highly accurate replica of the original wax pattern. It is then cleaned, finished, and, if necessary, stained or glazed to achieve its final appearance.

Understanding the Trade-offs and Critical Factors

Press molding offers exceptional results, but it is a technique that demands precision and control. Success is contingent on managing several key variables.

Proper Burnout is Non-Negotiable

An incomplete burnout cycle is a primary source of failure. Any residual carbon from the wax can contaminate the ceramic, causing discoloration, porosity, or a complete miscast.

Strict Temperature and Time Control is Essential

The entire process operates within a very specific thermal window. If the furnace or mold is too cold, the ceramic ingot won't flow properly, resulting in an incomplete press.

Conversely, if the temperature is too high, the ceramic can become overly fluid and may react with the investment material, ruining the surface finish and accuracy.

Equipment and Material Specificity

This is not a low-cost technique. It requires a significant investment in a calibrated pressing furnace, specialized investment materials, and high-quality ceramic ingots. Each component is designed to work as part of a system.

Making the Right Choice for Your Goal

Press molding is a powerful but specific technique. To determine if it suits your needs, consider your primary objective.

- If your primary focus is unmatched precision for items like dental crowns, veneers, or inlays: This is the ideal technique, as it excels at creating parts with perfect fit and anatomical detail.

- If your primary focus is achieving the highest possible material density and strength: The pressure used in this process minimizes internal voids and porosity, creating a final product that is exceptionally strong and durable.

- If your primary focus is rapid production of simple artistic forms: Other methods like slip casting, jiggering, or hand-building are far more efficient and cost-effective for these applications.

Ultimately, press molding is the definitive choice when precision and material integrity cannot be compromised.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Use | High-precision components (e.g., dental crowns, technical parts) |

| Key Advantage | Exceptional accuracy and material density/strength |

| Process Type | Heat and pressure forming with a disposable mold |

| Ideal For | Applications where precision and integrity are critical |

Need to create high-precision, dense ceramic components?

At KINTEK, we specialize in providing the advanced lab equipment and consumables—including pressing furnaces and high-quality ceramic ingots—that are essential for a successful press molding process. Our expertise ensures you achieve the material integrity and accuracy your projects demand.

Contact our experts today to discuss how we can support your precision ceramic manufacturing needs.

Visual Guide

Related Products

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Double Plate Heating Press Mold for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

People Also Ask

- What is a pellet mill used for? Transforming Powders into Precise Samples and Components

- What is the difference between EDS and XRF? EDS for Microanalysis, XRF for Bulk Analysis

- What is a KBr pellet? A Guide to Preparing Solid Samples for IR Spectroscopy

- How do you do the KBr pellet method? A Step-by-Step Guide to Perfect FTIR Sample Preparation

- Why only KBr is used in IR spectroscopy? The Truth About the Best Material for Your Sample