There is technically no such thing as an "SPS metal." This term is a common shorthand that refers to a metal or alloy produced using a manufacturing process called Spark Plasma Sintering (SPS). It is a powerful method for rapidly consolidating powders into a solid, high-density bulk material, not a unique type of material itself.

Spark Plasma Sintering is not a specific alloy but a powerful consolidation technique. Its key advantage lies in using pulsed electrical current and pressure to rapidly fuse powders, creating highly dense, fine-grained materials that are often impossible to produce with traditional methods.

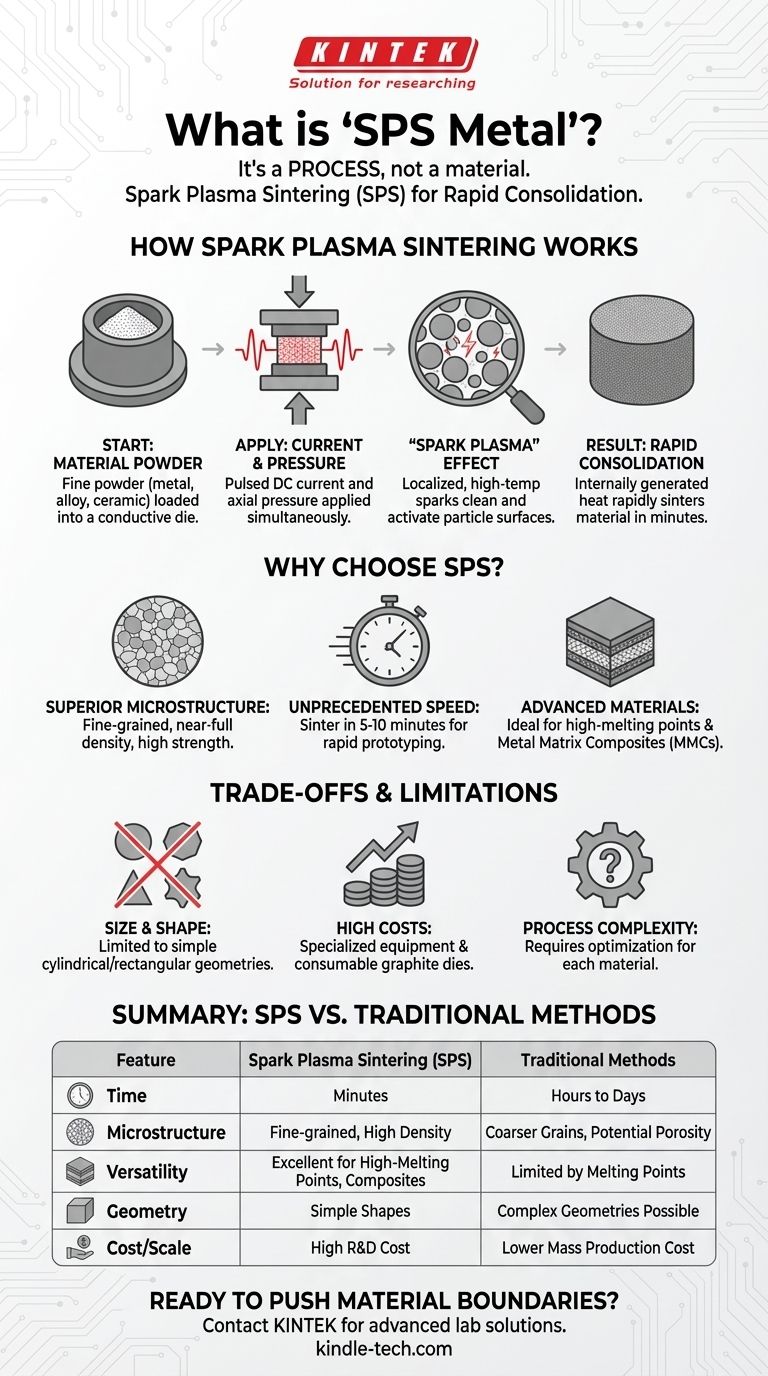

How Spark Plasma Sintering Works

To understand the materials it produces, you must first understand the process. SPS is fundamentally different from traditional melting or pressing techniques because of how it applies energy.

The Starting Point: Material Powder

The process begins not with a solid block of metal, but with a fine powder of the desired metal, alloy, or even ceramic. This powder is loaded into a conductive die, which is typically made of graphite.

The Core Mechanism: Current and Pressure

Two key forces are applied simultaneously: a strong axial pressure from above and below, and a high-amperage, pulsed direct electrical current that passes directly through the powder particles.

The "Spark Plasma" Effect

The pulsed current is the defining feature. It generates localized, high-temperature spark discharges between the individual powder particles. This effect microscopically cleans the surfaces of the particles and activates them, dramatically enhancing their ability to bond together.

The Result: Rapid Consolidation

Because the heat is generated internally within the powder itself, the entire mass heats up incredibly quickly. This allows the material to be sintered and densified in a matter of minutes, rather than the hours required for conventional furnace-based methods.

Why Choose SPS Over Traditional Methods?

The unique mechanism of SPS unlocks material properties that are difficult or impossible to achieve through conventional means like casting, forging, or hot pressing.

Superior Density and Microstructure

The extreme speed of the SPS process prevents the microscopic grains within the metal from growing too large. This results in a fine-grained microstructure, which directly contributes to higher strength, hardness, and overall improved mechanical performance. The combination of pressure and heat also achieves near-full density, eliminating the porosity that can weaken parts.

Unprecedented Speed

Consolidating a material in 5-10 minutes instead of 8-10 hours is a revolutionary leap. This allows for rapid prototyping and iteration during materials development.

Processing Advanced and Novel Materials

SPS excels at processing materials with extremely high melting points (like tungsten or tantalum) that are challenging for traditional casting. It is also a leading method for creating metal matrix composites (MMCs) by embedding ceramic particles into a metal powder, creating materials with customized properties.

Understanding the Trade-offs and Limitations

While powerful, SPS is not a universal solution. Its application is specific and comes with clear constraints.

Size and Shape Constraints

The process is limited to the simple cylindrical or rectangular shapes of the dies used. It cannot produce the large, complex geometries possible with casting or additive manufacturing. Part size is also significantly limited by the capacity of the press and power supply.

High Equipment and Tooling Costs

SPS systems are specialized, expensive machines. The graphite dies used are consumables with a limited lifespan, especially at high temperatures and pressures. This makes the process best suited for high-value applications.

Process Complexity

Achieving optimal results requires careful optimization of many parameters, including heating rate, pressure, pulse pattern, and vacuum level. This development work must be performed for each specific material.

Making the Right Choice for Your Goal

Considering a material made via SPS depends entirely on your project's primary objective.

- If your primary focus is maximum performance: Materials made via SPS often exhibit superior strength and density due to their fine-grained microstructure, making them ideal for high-stress aerospace, defense, or industrial applications.

- If your primary focus is developing novel materials: SPS is the go-to method for creating advanced composites, functionally graded materials, and consolidating powders that cannot be processed conventionally.

- If your primary focus is rapid prototyping of material samples: For small, simple-geometry components, SPS can produce a dense, finished part from powder in minutes, drastically shortening development cycles.

Understanding that SPS is a powerful process allows you to focus on the unique material properties it can unlock for your specific application.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Methods (e.g., Casting, Hot Pressing) |

|---|---|---|

| Process Time | Minutes | Hours to Days |

| Microstructure | Fine-grained, high density | Coarser grains, potential porosity |

| Material Versatility | Excellent for high-melting-point metals, composites | Limited by melting points and material compatibility |

| Part Geometry | Simple shapes (cylindrical, rectangular) | Complex geometries possible |

| Cost & Scalability | High equipment cost, ideal for R&D and high-value parts | Lower cost for mass production |

Ready to push the boundaries of material performance?

At KINTEK, we specialize in providing advanced lab equipment and consumables for materials research and development. Whether you're developing novel metal matrix composites, prototyping high-strength alloys, or exploring the limits of Spark Plasma Sintering, our expertise and solutions can help you achieve superior results.

Contact us today to discuss how our solutions can accelerate your materials innovation.

Get in Touch

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of using vacuum hot pressing for Al3Hf-Al composites? Achieving 99% Material Density

- Why is a high-precision temperature control system in a vacuum hot press furnace critical? Perfect Cu-Ti3SiC2 Synthesis

- How does high-precision pressure control of a vacuum hot press furnace influence graphite/copper composites?

- What equipment is used in the sintering process? From Basic Furnaces to Advanced HIP & SPS Systems

- What temperature do you need to make diamonds? Unlock the Power of Heat and Pressure

- How long does spark plasma sintering take? Complete SPS cycles in 5-20 minutes

- What are the spark plasma sintering parameters? Master Temperature, Pressure, and Time for Optimal Densification

- What is the pressure of hot isostatic press? Achieve Full Density & Superior Material Performance