The primary advantage of a single punch tablet press lies in its operational simplicity, small footprint, and efficiency with minimal material. These characteristics make it the ideal tool for early-stage research and development, where the goal is to test the feasibility of a powder formulation without committing large quantities of expensive ingredients.

A single punch tablet press excels in a laboratory setting for initial formulation testing. Its value comes from its ability to confirm a powder's basic compressibility with minimal waste, but it is crucial to understand that its operating principles do not replicate the high-speed dynamics of a full-scale production environment.

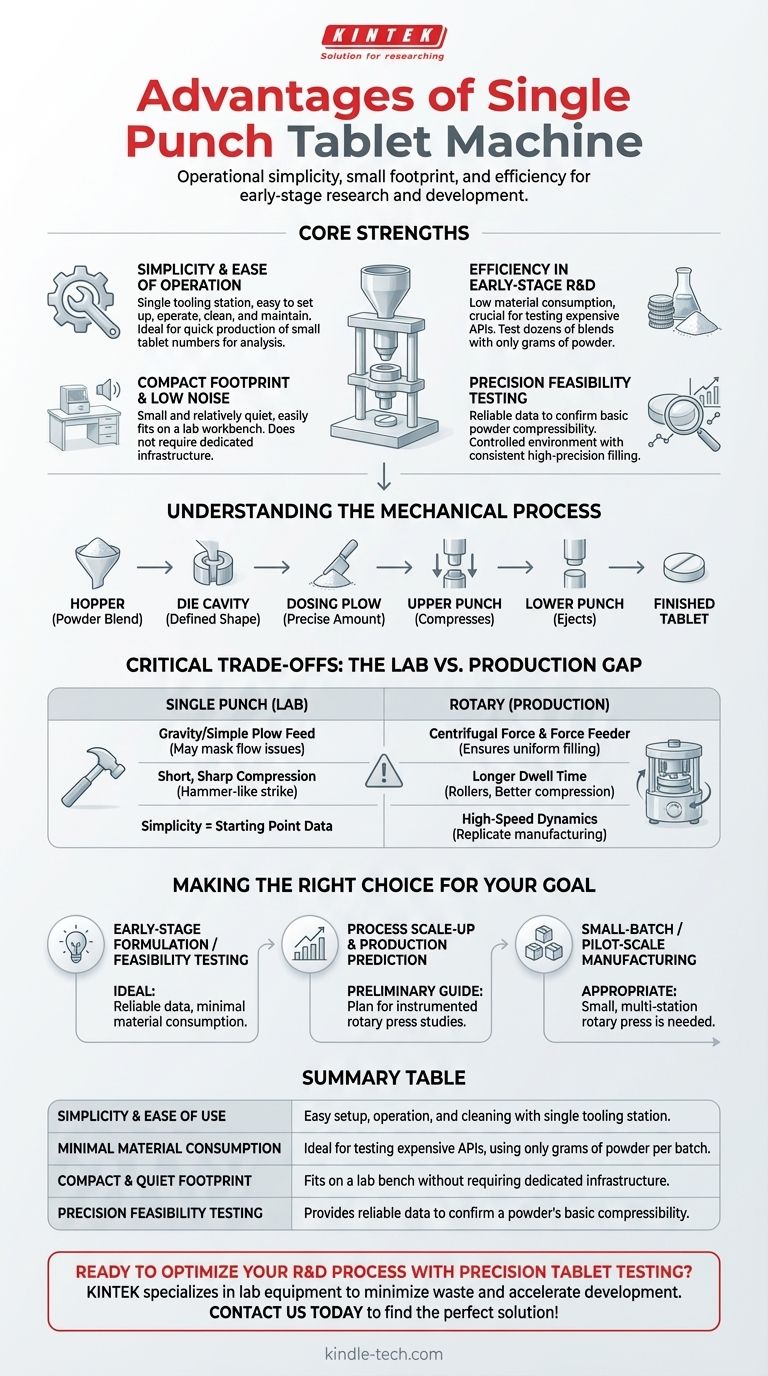

The Core Strengths of a Single Punch Press

A single punch press, also known as an eccentric press, is designed for precision and efficiency on a small scale. Its advantages are best understood in the context of a research lab, not a factory floor.

Simplicity and Ease of Operation

The machine uses a single tooling station consisting of one upper punch, one lower punch, and one die. This simple mechanical design makes it incredibly easy to set up, operate, clean, and maintain compared to complex multi-station rotary presses.

Its "stamping" or hammer-like motion is straightforward, allowing a technician to quickly produce a small number of tablets for analysis.

Efficiency in Early-Stage R&D

The most significant advantage is its low consumption of material. When developing formulations with expensive Active Pharmaceutical Ingredients (APIs), minimizing waste is critical.

A single punch press allows formulators to test dozens of blends using only a few grams of powder for each batch, making it an invaluable tool for initial feasibility studies.

Compact Footprint and Low Noise

These machines are small and relatively quiet. They easily fit on a workbench in a lab environment without requiring the dedicated space, power, or sound-dampening infrastructure of a larger production machine.

Precision Feasibility Testing

The primary function of a single punch press is to answer a simple question: "Can this powder be compressed into a tablet?" It provides a controlled environment to assess a formulation's basic binding and compression characteristics.

The high precision of filling ensures that each test tablet is created under consistent conditions, providing reliable data for initial analysis.

Understanding the Mechanical Process

The simple mechanics of a single punch press are key to its role in development. The entire process revolves around the action at its single station.

The Single Station Design

The machine's hopper holds the powder blend. The powder flows into a die cavity, which defines the shape and size of the tablet.

A stationary lower punch forms the bottom of the cavity, while a moving upper punch descends with immense force to compress the powder.

The Compression Cycle

First, a dosing plow pushes a precise amount of powder over the die, filling the cavity. The upper punch then drives down into the die, applying the compressive force.

After compression, the upper punch retracts, and an ejection cam pushes the lower punch upward, ejecting the finished tablet from the die cavity. This cycle repeats for each tablet.

Critical Trade-offs: The Lab vs. Production Gap

The simplicity of a single punch press is also its primary limitation. The data it produces is a starting point, not a final predictor of manufacturing success.

The Absence of Centrifugal Force

High-speed rotary presses use centrifugal force to sling powder into the die cavities, a critical factor for ensuring uniform filling at thousands of tablets per minute. A single punch press relies on gravity and a simple plow, which may mask powder flow issues that would halt a production line.

Different Feeder Dynamics

A rotary press uses a complex, powered "force feeder" to ensure dies are filled completely and consistently at speed. A formulation that works perfectly in the slow, simple feed system of a single punch press may fail to perform in a high-speed feeder.

Dwell Time and Compression Profile

The "hammer-like" strike of a single punch press provides a very short, sharp compression. Rotary presses roll the punches through a compression station, resulting in a longer "dwell time" where pressure is applied.

This difference can significantly impact tablet hardness, dissolution rates, and friability. A tablet that is perfect off a single punch press may cap, laminate, or fracture on a rotary press due to these different compression dynamics.

Making the Right Choice for Your Goal

Your choice of press depends entirely on the stage and objective of your project.

- If your primary focus is early-stage formulation or feasibility testing: The single punch press is the ideal tool, providing reliable data with minimal material consumption.

- If your primary focus is process scale-up and predicting production performance: Use data from a single punch press as a preliminary guide, but plan for critical follow-up studies on an instrumented rotary press.

- If your primary focus is small-batch or pilot-scale manufacturing: A single punch press is far too slow; a small, multi-station rotary press is the appropriate choice.

Understanding its role as a specialized R&D instrument is the key to leveraging its true advantages.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Simplicity & Ease of Use | Easy setup, operation, and cleaning with a single tooling station. |

| Minimal Material Consumption | Ideal for testing expensive APIs, using only grams of powder per batch. |

| Compact & Quiet Footprint | Fits on a lab bench without requiring dedicated infrastructure. |

| Precision Feasibility Testing | Provides reliable data to confirm a powder's basic compressibility. |

Ready to optimize your R&D process with precision tablet testing? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our single punch tablet presses are designed to help you minimize waste and accelerate your formulation development. Contact us today to find the perfect solution for your lab!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What does a tablet punching machine consist of? Core Components for Efficient Tablet Production

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What components of a tablet press define the size and shape of the tablets? Mastering Die and Punch Tooling

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production

- How fast is the rotary tablet press? Unlock Peak Production Speeds for Your Tablets

- What is the difference between pelleting and pelletizing? Understand the Core Agglomeration Methods

- Are wood pellets made from sawdust? Unlock the Secret to High-Performance Fuel

- What do you press pills with? The Essential Guide to Tablet Press Machines