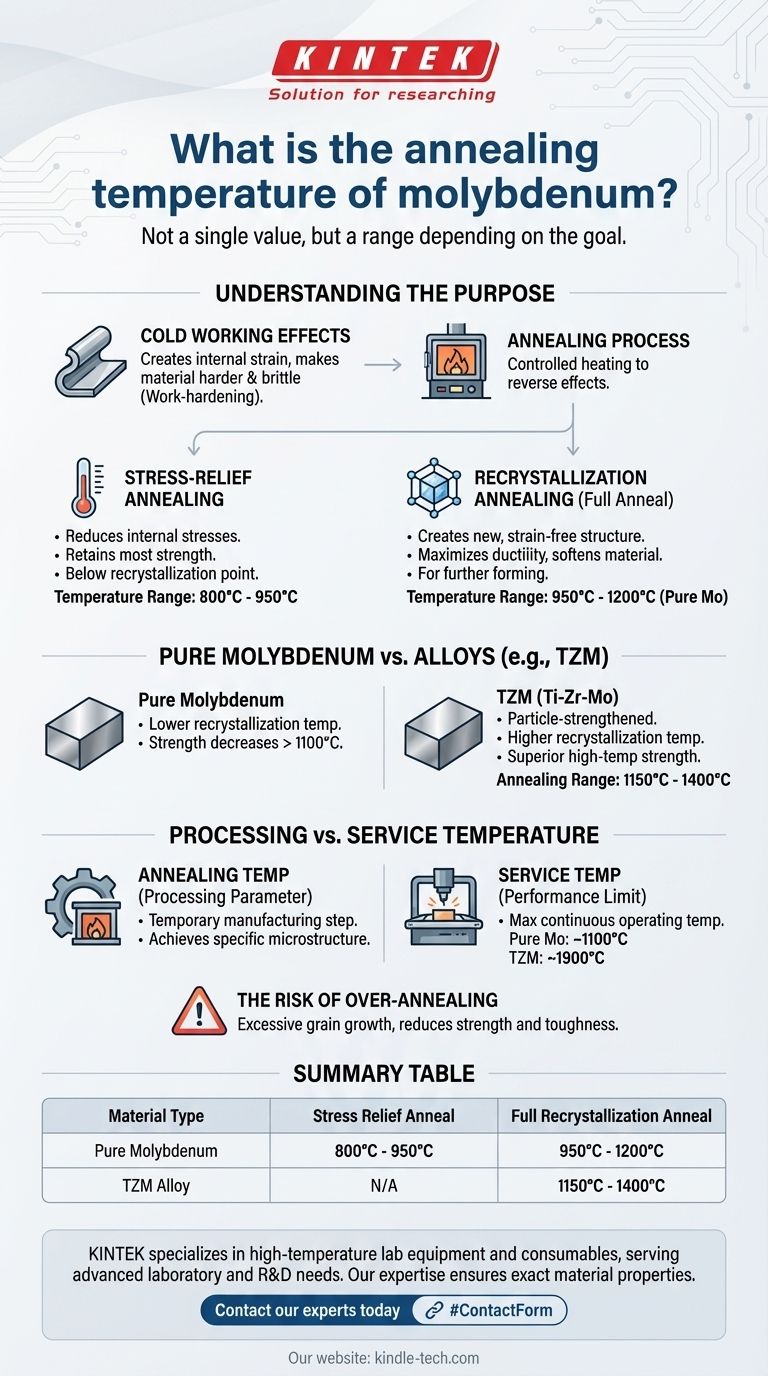

For pure, previously worked molybdenum, the full annealing (recrystallization) temperature is not a single value but a range, typically between 950°C and 1200°C (1740°F and 2190°F). The exact temperature depends on the amount of prior cold work and the desired final grain structure. A lower-temperature stress relief anneal can be performed between 800°C and 950°C.

The term "annealing temperature" for molybdenum is imprecise. The correct temperature depends entirely on the goal—whether it's a low-temperature cycle to relieve internal stress or a higher-temperature cycle to fully reverse work-hardening and restore ductility.

Understanding the Purpose of Annealing Molybdenum

When molybdenum is mechanically formed, bent, or machined (a process known as cold working), its internal crystalline structure becomes strained. This makes the material harder and more brittle, a phenomenon called work-hardening.

Annealing is a controlled heating process designed to reverse these effects. It is not one single process but falls into two main categories.

Stress-Relief Annealing

This process is used to reduce the internal stresses built up during fabrication without significantly softening the material.

It is performed at a lower temperature, typically in the range of 800°C to 950°C. This is below the point of recrystallization, so the material retains most of the strength gained from work-hardening.

Recrystallization Annealing

This is what is commonly referred to as a "full anneal." The goal is to create a new, strain-free grain structure within the metal.

This process fully softens the material, maximizing its ductility and making it suitable for further forming. It requires a higher temperature, generally between 950°C and 1200°C for pure molybdenum.

Pure Molybdenum vs. Its Alloys

The user's question specified "molybdenum," but it's critical to distinguish between the pure element and its high-performance alloys. Additives fundamentally change the material's behavior at high temperatures.

Pure Molybdenum

Pure molybdenum offers excellent thermal and electrical conductivity but has a lower recrystallization temperature compared to its alloys. Its strength begins to decrease significantly at temperatures above 1100°C.

High-Performance Alloys (like TZM)

TZM (Titanium-Zirconium-Molybdenum) is a particle-strengthened alloy. The small additions of titanium and zirconium create fine carbide particles that pin the material's grain boundaries.

This structure gives TZM a much higher recrystallization temperature and superior strength (creep resistance) at elevated temperatures. The annealing temperature for TZM is consequently higher, often in the range of 1150°C to 1400°C.

Understanding the Trade-offs: Processing vs. Service Temperature

A common point of confusion is the difference between the temperature used to process a material and the temperature the final product can withstand.

Annealing Temperature: A Processing Parameter

Annealing is a temporary step in the manufacturing workflow. The material is heated to this temperature in a controlled environment (like a vacuum furnace) to achieve a specific microstructure and set of mechanical properties.

Service Temperature: A Performance Limit

The service temperature is the maximum temperature a finished component can operate at continuously without failing. For example, a pure molybdenum boat's recommended maximum service temperature is around 1100°C. Above this, it begins to soften and deform under load.

A TZM boat, due to the alloy's superior high-temperature strength, can have a service temperature up to 1900°C. Its higher annealing temperature is a direct reason for this superior performance.

The Risk of Over-Annealing

Using a temperature that is too high or holding the material at temperature for too long can be detrimental. This can cause excessive grain growth, which reduces the material's strength, toughness, and overall performance.

How to Apply This to Your Project

Choosing the correct thermal cycle is essential for achieving your desired outcome.

- If your primary focus is relieving stress after machining with minimal loss of hardness: Use a lower-temperature stress-relief anneal (approx. 800-950°C).

- If your primary focus is restoring maximum ductility for further forming: Use a full recrystallization anneal in the appropriate range for your material (e.g., 950-1200°C for pure Mo).

- If you are working with a TZM alloy: You must use a significantly higher annealing temperature to overcome its inherent high-temperature strength.

Controlling the thermal processing of molybdenum is the key to unlocking its intended mechanical properties.

Summary Table:

| Material Type | Stress Relief Anneal | Full Recrystallization Anneal |

|---|---|---|

| Pure Molybdenum | 800°C - 950°C | 950°C - 1200°C |

| TZM Alloy | N/A | 1150°C - 1400°C |

Need precise thermal processing for your molybdenum components?

KINTEK specializes in high-temperature lab equipment and consumables, serving advanced laboratory and R&D needs. Our expertise ensures you achieve the exact material properties—from stress relief to full recrystallization—for your specific application.

Contact our experts today to discuss your project requirements and discover the right solution for your lab.

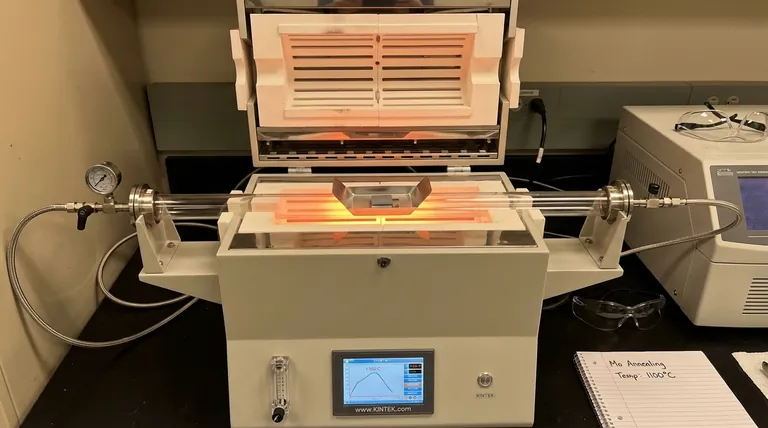

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the process of an arc melting furnace? The Key to High-Volume Steel Scrap Recycling

- How does pyrolysis work? Unlock the Power of Thermal Decomposition for Waste Transformation

- How is a high-vacuum or atmosphere sintering furnace utilized for nanocrystalline stainless steel thermal stability?

- What is the range of a vacuum leak test? Choose the Right Sensitivity for Your System

- What is physical Vapour deposition in crystal growth? Master Atomic-Level Thin Film Fabrication

- What role do high-temperature annealing furnaces play in evaluating materials after ion beam irradiation?

- What role do vacuum pumps and pressure control systems play in studying the oxidation reactions of metallic yttrium?

- What materials can be tempered? Unlock the Key to Hardness and Toughness in Steel