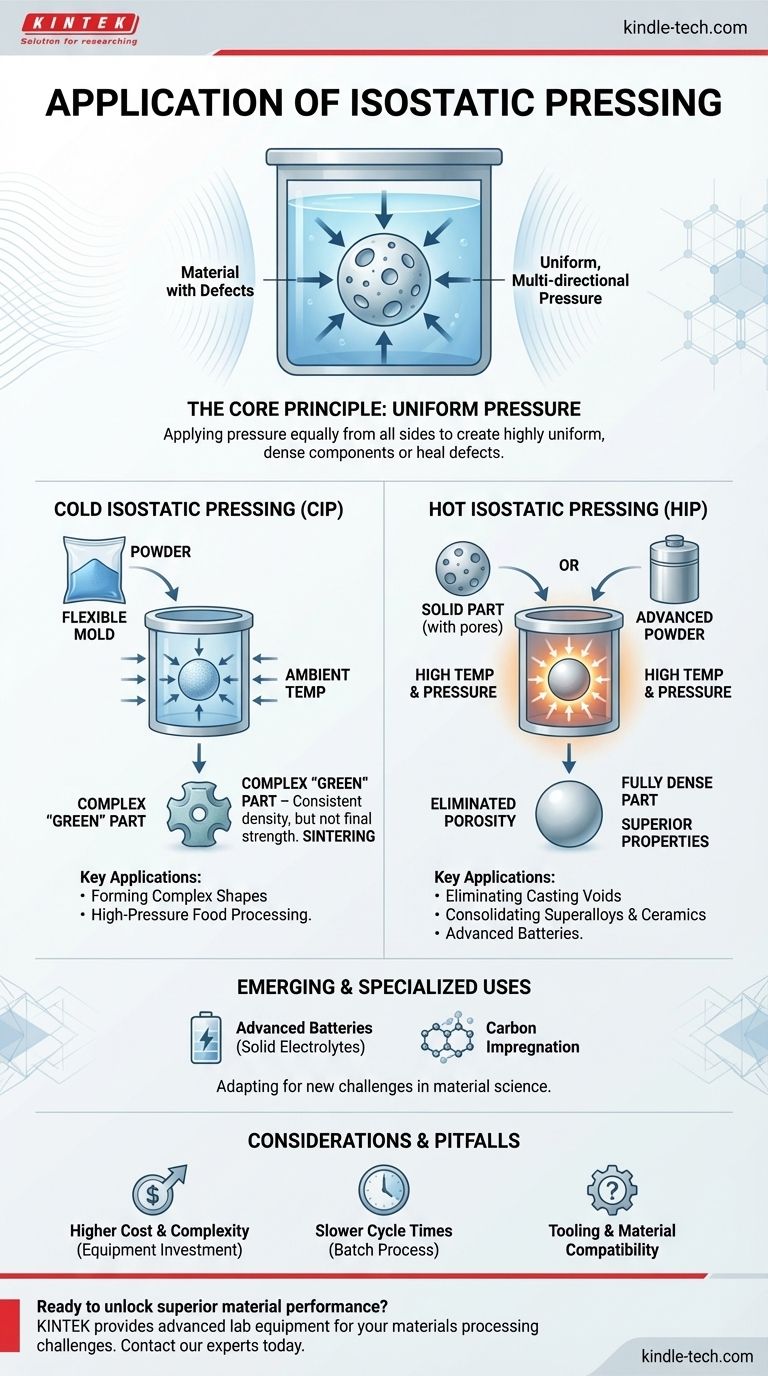

At its core, isostatic pressing is a material processing technique used to create highly uniform, dense components from powders or to heal defects in already solid parts. Its applications span from producing critical, high-performance aerospace components and advanced ceramics to consolidating materials for next-generation batteries and even processing certain foods.

The fundamental advantage of isostatic pressing is its use of uniform, multi-directional pressure. This allows it to either form complex powder shapes with consistent density (Cold Pressing) or eliminate internal voids in solid parts to achieve maximum theoretical density and superior material properties (Hot Pressing).

The Core Principle: Uniform Pressure

What “Isostatic” Really Means

The term isostatic means that pressure is applied equally and simultaneously from all directions.

Think of an object submerged deep underwater. The water exerts pressure on it from all sides at once, not just from the top down. This is the exact principle behind isostatic pressing, which prevents the density gradients and internal stresses common in traditional unidirectional pressing.

The Primary Goal: Uniformity and Density

By applying pressure uniformly, the process compacts material powders into a solid mass with very consistent density throughout.

For already-solid parts, this same all-around pressure can collapse and permanently close internal defects like pores or voids, dramatically improving the material's strength and reliability.

Key Applications by Process Type

The specific application depends on whether the process is performed "cold" or "hot," each solving a different set of engineering problems.

Cold Isostatic Pressing (CIP): Forming the “Green” Part

CIP uses uniform pressure at ambient temperatures, typically to compact powders into a solid, handleable shape known as a "green" part.

This green part is not yet at its final strength but has uniform density, making it ideal for subsequent processing like sintering. It is a crucial step for forming complex shapes that would be difficult or impossible to create with other methods. A specialized application includes high-pressure processing of foodstuffs, where the uniform pressure acts without significant heat.

Hot Isostatic Pressing (HIP): Achieving Full Consolidation

HIP combines high pressure with elevated temperatures to fully consolidate materials through a process called solid-state diffusion.

Its primary applications are in high-performance fields:

- Eliminating Porosity: It removes residual voids from parts made via powder metallurgy or casting, achieving up to 100% of the material's theoretical density.

- Consolidating Powders: It can turn advanced powders, like superalloys or ceramics, directly into fully dense, near-net-shape components.

Specific examples include the densification of ceramics, consolidation of superalloy powders for jet engine parts, and manufacturing of cemented carbides for cutting tools.

Emerging and Specialized Applications

The technology is constantly being adapted for new challenges. It is anticipated for the densification of components in advanced batteries, such as thin solid electrolyte films.

Other specialized uses include carbon impregnation, where the high pressure forces carbon deep into a porous material structure.

Common Pitfalls and Considerations

Process Complexity and Cost

Isostatic pressing, particularly HIP, requires significant capital investment in high-pressure vessels and control systems. The complexity and cost are higher than many conventional manufacturing processes.

Slower Cycle Times

As a batch process, isostatic pressing can have longer cycle times compared to continuous compaction methods. This can be a limiting factor for high-volume production where speed is the primary concern.

Tooling and Material Compatibility

While versatile, the process requires flexible tooling (for CIP) or encapsulation canisters (for HIP) that must be compatible with the material being processed and able to withstand the intense pressure.

Making the Right Choice for Your Goal

Selecting the appropriate method depends entirely on your material and end-goal for the component.

- If your primary focus is creating a complex, uniform "green" part from powder for subsequent sintering: CIP is the most effective and economical choice for achieving consistent pre-sintered density.

- If your primary focus is achieving maximum theoretical density and eliminating all internal porosity in a critical component: HIP is the necessary process for unlocking superior, flaw-free material performance.

- If your primary focus is exploring advanced material consolidation for new technologies like solid-state batteries: Both CIP and HIP are becoming essential tools for research, development, and production.

Ultimately, isostatic pressing provides an unparalleled method for achieving a level of material uniformity and density that is unattainable with traditional compaction techniques.

Summary Table:

| Process Type | Primary Application | Key Benefit |

|---|---|---|

| Cold Isostatic Pressing (CIP) | Forming complex "green" parts from powder | Uniform density for subsequent sintering |

| Hot Isostatic Pressing (HIP) | Eliminating porosity in cast or sintered parts | Achieves near 100% theoretical density |

Ready to unlock superior material performance with isostatic pressing?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for your materials processing challenges. Whether you are developing next-generation batteries, manufacturing critical aerospace components, or consolidating advanced ceramics, our expertise can help you achieve the uniform density and flawless material properties your projects demand.

Contact our experts today to discuss how our solutions can enhance your lab's capabilities and drive your innovations forward.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the scale of hot isostatic pressing? From Lab Research to Industrial Production

- How do warm isostatic presses improve dry electrode performance? Enhance ASSB Conductivity with Heat & Pressure

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- Why is a Hot Isostatic Press (HIP) required for Eu:Y2O3 samples? Unlock Optical-Grade Ceramic Transparency

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is the purpose of using 160 MPa pressure in HIP for Inconel 718? Achieve Aerospace-Grade Alloy Density

- What are the advantages of HIP over conventional PM? Achieve Full Density for Superior Performance

- What is hot isostatic pressing treatment porosity? Achieve 100% Material Density for Critical Components