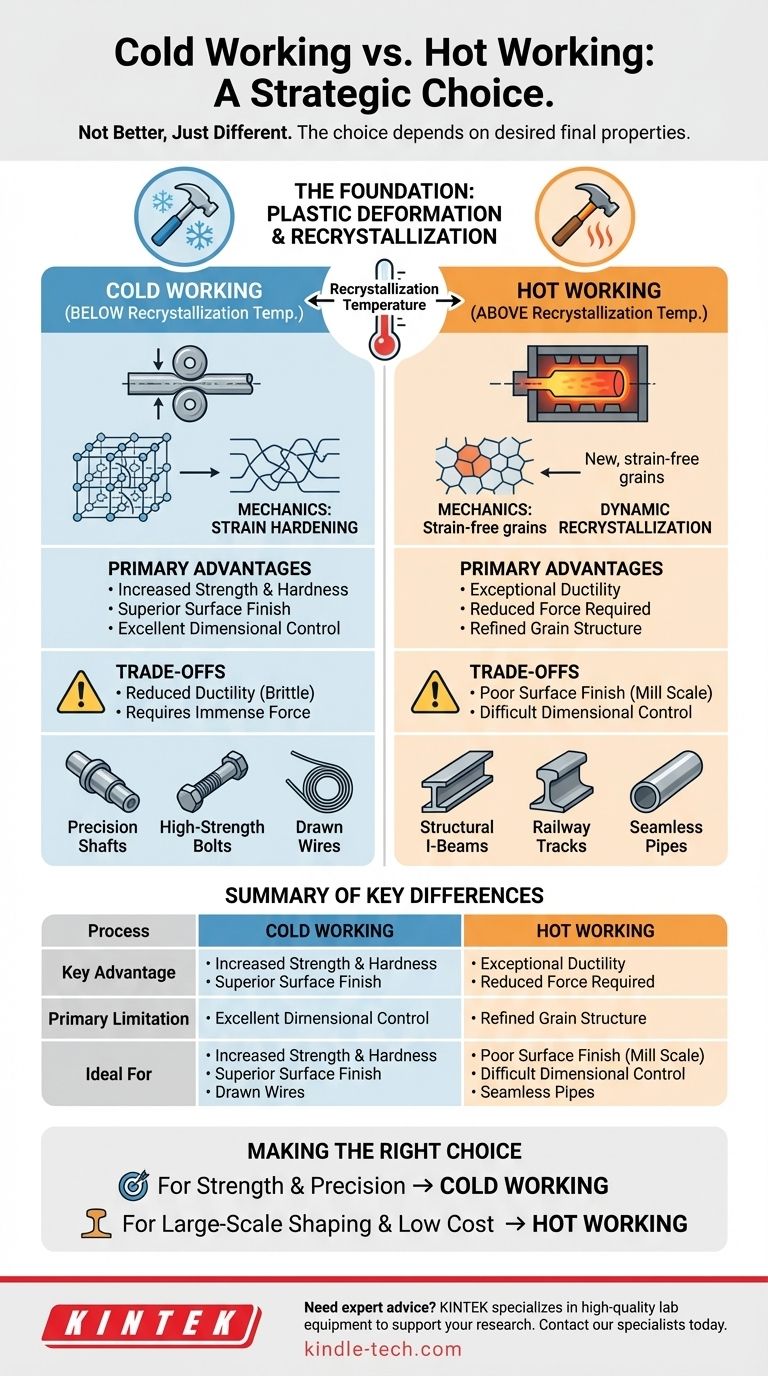

The question of superiority between cold working and hot working is based on a common misconception. Cold working is not inherently "better"; it is chosen when the primary goals are to increase a metal's strength, improve its surface finish, and achieve tight dimensional tolerances, as it fundamentally alters the material's internal crystal structure through a process called strain hardening.

The choice between cold and hot working is not a matter of which process is superior, but a strategic decision based on the desired final properties of the component. Hot working prioritizes formability and cost-effectiveness for large deformations, while cold working prioritizes strength, hardness, and precision.

The Foundation: Understanding Metal "Working"

To grasp the difference, we must first define what "working" a metal means and the critical role temperature plays.

What is Plastic Deformation?

All metalworking involves plastic deformation—permanently changing the shape of a material by applying force. This is achieved by moving dislocations, or imperfections, within the metal's crystal lattice.

The Role of Recrystallization Temperature

The key distinction between hot and cold working is the recrystallization temperature. This is the temperature at which a deformed metal can form new, strain-free crystal grains.

- Cold Working is performed below this temperature.

- Hot Working is performed above this temperature.

The Mechanics of Cold Working

Cold working strengthens a metal by making it harder for dislocations to move.

How It Works: Strain Hardening

When a metal is cold worked, dislocations multiply and tangle with each other, much like a tangled net. This entanglement acts as a barrier, impeding further dislocation movement.

To deform the metal further requires significantly more force. This phenomenon is known as strain hardening or work hardening, which results in increased strength and hardness.

Primary Advantages of Cold Working

- Increased Strength and Hardness: Strain hardening directly improves the metal's mechanical properties.

- Superior Surface Finish: Because there is no high-temperature oxidation, the resulting surface is smooth and free of scale.

- Excellent Dimensional Control: The absence of high heat and subsequent cooling prevents warping and shrinkage, allowing for very precise tolerances.

The Mechanics of Hot Working

Hot working uses thermal energy to make large-scale deformation easier and more efficient.

How It Works: Dynamic Recrystallization

Working a metal above its recrystallization temperature allows new, strain-free crystals to form continuously as the material is being deformed. This process, called dynamic recrystallization, effectively repairs the microstructure as it is being worked.

Because the material constantly "heals" itself, strain hardening does not occur. The metal remains soft and ductile throughout the process.

Primary Advantages of Hot Working

- Exceptional Ductility: The high temperature allows for massive changes in shape without the risk of fracture.

- Reduced Force Required: The metal is softer and more malleable, requiring far less energy and smaller equipment to deform.

- Refined Grain Structure: The process can break down coarse grains and heal internal defects like porosity from the initial casting process.

Understanding the Trade-offs

Neither process is without its limitations. The "costs" of choosing one method are the benefits you sacrifice from the other.

The Cost of Cold Working: Brittleness and Force

The primary downside of cold working is that as strength increases, ductility decreases. The metal becomes more brittle and prone to cracking if deformed too much. It also requires immense forces, limiting the size and degree of shaping possible in a single step.

The Limitations of Hot Working: Precision and Finish

During hot working, a layer of oxide, known as mill scale, forms on the metal's surface. This results in a rough, poor surface finish that often requires secondary cleaning operations.

Furthermore, as the component cools from a high temperature, it shrinks and can warp. This makes achieving tight dimensional tolerances extremely difficult.

Making the Right Choice for Your Application

The decision must be driven by the end-use requirements of the component.

- If your primary focus is strength and precision: Cold working is the correct choice. This is ideal for components like high-strength bolts, precision shafts, and drawn wires.

- If your primary focus is large-scale shaping and low cost: Hot working is the necessary process. This is used for manufacturing structural I-beams, railway tracks, and seamless pipes.

- If your primary focus is a balance of properties: A combination is often used. A part may be hot-rolled into a basic shape, then cold-finished to achieve the final dimensions and desired strength.

Ultimately, mastering material selection means understanding that you are always managing the fundamental trade-off between a material's strength and its ductility.

Summary Table:

| Process | Key Advantage | Primary Limitation | Ideal For |

|---|---|---|---|

| Cold Working | Increased strength, superior surface finish, tight tolerances | Reduced ductility, requires high force | Precision shafts, high-strength bolts, drawn wires |

| Hot Working | Exceptional ductility, large-scale shaping, refined grain structure | Poor surface finish (mill scale), difficult dimensional control | Structural I-beams, railway tracks, seamless pipes |

Need expert advice on the right metalworking process for your lab's materials?

At KINTEK, we specialize in providing high-quality lab equipment and consumables to support your research and development. Whether you're working on precision components requiring cold working or large-scale material shaping, our team can help you select the ideal tools for your specific application.

Contact our specialists today via our Contact Form to discuss how we can enhance your laboratory's capabilities and achieve your material property goals.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- How does a laboratory isostatic press contribute to the fabrication of LAGP solid-state electrolyte pellets?

- What is cold isostatic pressing? Achieve Uniform Density for Complex Parts

- How does a cold isostatic press improve microhardness uniformity? Achieving Consistency in TiC10/Cu-Al2O3 Composites

- What types of materials are used for canisters in the HIP process? Optimized Choices for Material Densification

- What are the industrial applications of cold work? Achieve Superior Strength and Precision in Metal Parts

- How does isostatic pressing work? Achieve Perfectly Uniform Density for Complex Parts

- What is the purpose of using a laboratory hydraulic press or cold isostatic press? Optimize Your Electrolyte Quality

- What is isostatic pressing? Achieve Uniform Density and Complex Shapes