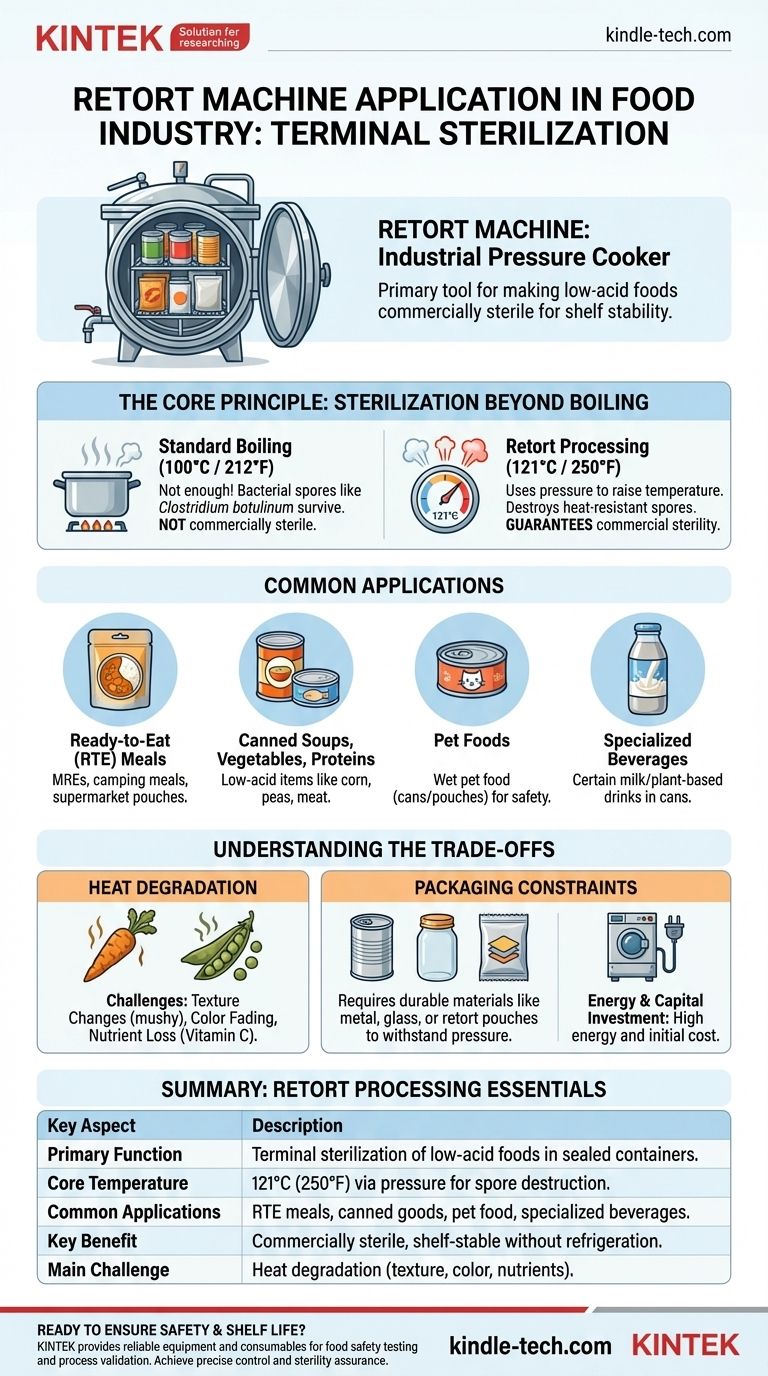

In the food industry, a retort machine is the primary tool for terminal sterilization. It functions as a large, industrial-scale pressure cooker that uses a combination of high temperature and pressure to make low-acid foods commercially sterile. This process is what allows products like canned soups, pouched meals, and wet pet foods to be shelf-stable for months or years without refrigeration.

The core purpose of a retort is to heat food inside its final sealed container to a temperature high enough—typically 121°C (250°F)—to destroy the most heat-resistant and dangerous bacterial spores, such as Clostridium botulinum. Standard boiling at 100°C (212°F) cannot achieve this, so the retort uses pressure to raise the boiling point of water and ensure food safety.

The Core Principle: Sterilization Beyond Boiling

Why Standard Boiling Isn't Enough

Many preservation methods, like pasteurization, kill common bacteria but are not sufficient for long-term shelf stability in low-acid foods (those with a pH above 4.6).

The primary concern is bacterial spores, which are dormant, highly resistant forms of bacteria. The spores of Clostridium botulinum, which can produce a deadly toxin, can survive boiling temperatures for hours.

How Pressure Creates Sterilizing Temperatures

A retort is a sealed pressure vessel. By increasing the pressure inside the chamber, the boiling point of water is elevated well above its normal 100°C (212°F).

This allows the processing environment to reach the industry-standard sterilization temperature of 121°C (250°F). At this temperature, a specific duration of exposure, known as the "F-zero" value, is calculated to guarantee the destruction of these dangerous spores.

The Goal: Commercial Sterility

The result of this process is a commercially sterile product. This means the food is free of microorganisms capable of reproducing under normal, non-refrigerated storage and distribution conditions.

This is distinct from complete sterility (the absence of all life), which is not the goal. The aim is to make the product safe and stable for its intended shelf life.

Common Applications of Retort Processing

Retort technology is the backbone of the shelf-stable food market. You will find it used for a wide range of products packaged in cans, glass jars, and flexible retort pouches.

Ready-to-Eat (RTE) Meals

Retort is essential for items like military MREs (Meals, Ready-to-Eat), camping meals, and supermarket meal pouches (e.g., curries, pasta dishes). The technology cooks the food directly in its pouch, making it safe and ready to heat and serve.

Canned Soups, Vegetables, and Proteins

This is the classic application. Low-acid foods like corn, peas, tuna, salmon, and chicken noodle soup rely on retort processing for their safety and long shelf life.

Pet Foods

The vast majority of wet pet foods, whether in cans or pouches, are sterilized using retorts. This ensures the product is safe for pets and convenient for owners.

Specialized Beverages

Certain milk-based or plant-based beverages that are not aseptically processed may be terminally sterilized in a retort, especially when packaged in cans or specific types of bottles.

Understanding the Trade-offs

While essential, retort processing is not without its challenges. The intense heat required for safety can impact the final product quality.

The Challenge of Heat Degradation

The same heat that ensures safety can also degrade the product's quality. This can manifest as:

- Texture Changes: Vegetables can become overly soft or mushy.

- Color Fading: Bright colors in vegetables like peas or carrots may dull.

- Nutrient Loss: Heat-sensitive vitamins, such as Vitamin C, can be partially destroyed during the long process.

Packaging Constraints

The packaging must be able to withstand the high temperatures and pressure differentials during the heating and cooling cycles. This limits choices to metal cans, glass jars, and specialized multi-layer plastic retort pouches. Standard plastic containers would warp or fail.

Energy and Capital Investment

Retorts are large, heavy-duty pieces of equipment that represent a significant capital investment. They also consume substantial amounts of energy in the form of steam, cooling water, and compressed air, making them costly to operate. Modern systems are increasingly focused on water and energy recovery to mitigate this.

Making the Right Choice for Your Product

Deciding on retort processing requires balancing the non-negotiable requirement of food safety with considerations for product quality and cost.

- If your primary focus is maximum shelf life and safety for low-acid foods: Retort processing is the industry-standard method and, in most cases, a regulatory necessity.

- If your primary focus is preserving delicate textures and fresh flavors: You must either invest in advanced retort systems (like those with agitation to speed up heating) or explore alternative preservation methods like High-Pressure Processing (HPP) or aseptic processing.

- If your primary focus is packaging flexibility: Your choice of container (can, jar, or pouch) is a critical decision that must be made early, as it must be validated to withstand the retort process and will heavily influence consumer perception.

Ultimately, retort processing is the proven, foundational technology that enables the safe, global distribution of shelf-stable foods.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Terminal sterilization of low-acid foods in sealed containers. |

| Core Temperature | 121°C (250°F) achieved via pressure to destroy bacterial spores. |

| Common Applications | Ready-to-eat meals, canned goods, wet pet food, and specialized beverages. |

| Key Benefit | Creates commercially sterile, shelf-stable products without refrigeration. |

| Main Challenge | Heat degradation affecting texture, color, and nutrients. |

Ready to ensure the safety and shelf life of your food products? KINTEK specializes in providing reliable laboratory equipment and consumables to support food safety testing and process validation. Whether you're developing new retort-sterilized products or optimizing your existing processes, our solutions help you achieve precise temperature control and sterility assurance. Contact our experts today to discuss how we can support your laboratory's critical role in food safety and quality control.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the 4 principles of autoclave? Master Steam Sterilization for Your Lab

- What is the temperature effective for sterilization using autoclave? Achieve Sterile Conditions for Your Lab

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- Which factors contribute to successful sterilization using an autoclave? Master the 3 Keys to Sterility

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab