In simple terms, arc melting is a metallurgical process that uses the intense heat from an electric arc to melt metals. This arc is essentially a controlled, high-temperature bolt of lightning created between an electrode and the metallic material itself, generating enough energy to turn solid metal into a liquid state.

The core principle of arc melting is its use of a direct, intensely localized heat source. This makes it exceptionally effective for metals with very high melting points or for creating precise, high-purity alloys where contamination must be minimized.

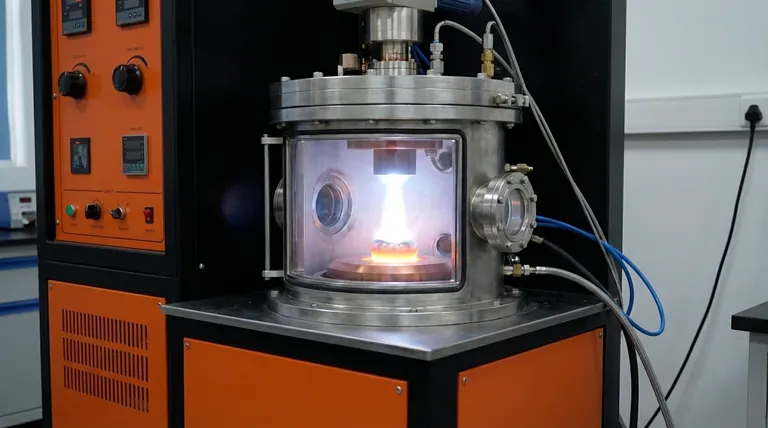

The Core Principle of Arc Melting

To understand its value, it's essential to break down how the process works. The technique is more than just applying heat; it's about controlling a powerful electrical phenomenon.

Creating the Electric Arc

An electric arc is a discharge of electricity that flows through a gap, creating a plasma. In an arc furnace, this arc is typically generated between a non-consumable electrode (often made of tungsten) and the raw metal you intend to melt, which acts as the other electrode.

Generating Intense, Localized Heat

The plasma created by the arc can reach thousands of degrees Celsius. This extreme heat is transferred directly to the surface of the metal, causing rapid and efficient melting in a very localized area.

Common Applications

Because it can achieve such high temperatures, arc melting is fundamental for several key tasks. It is used for alloying (mixing multiple metals), creating novel material compositions, and producing small, high-purity samples for research and development.

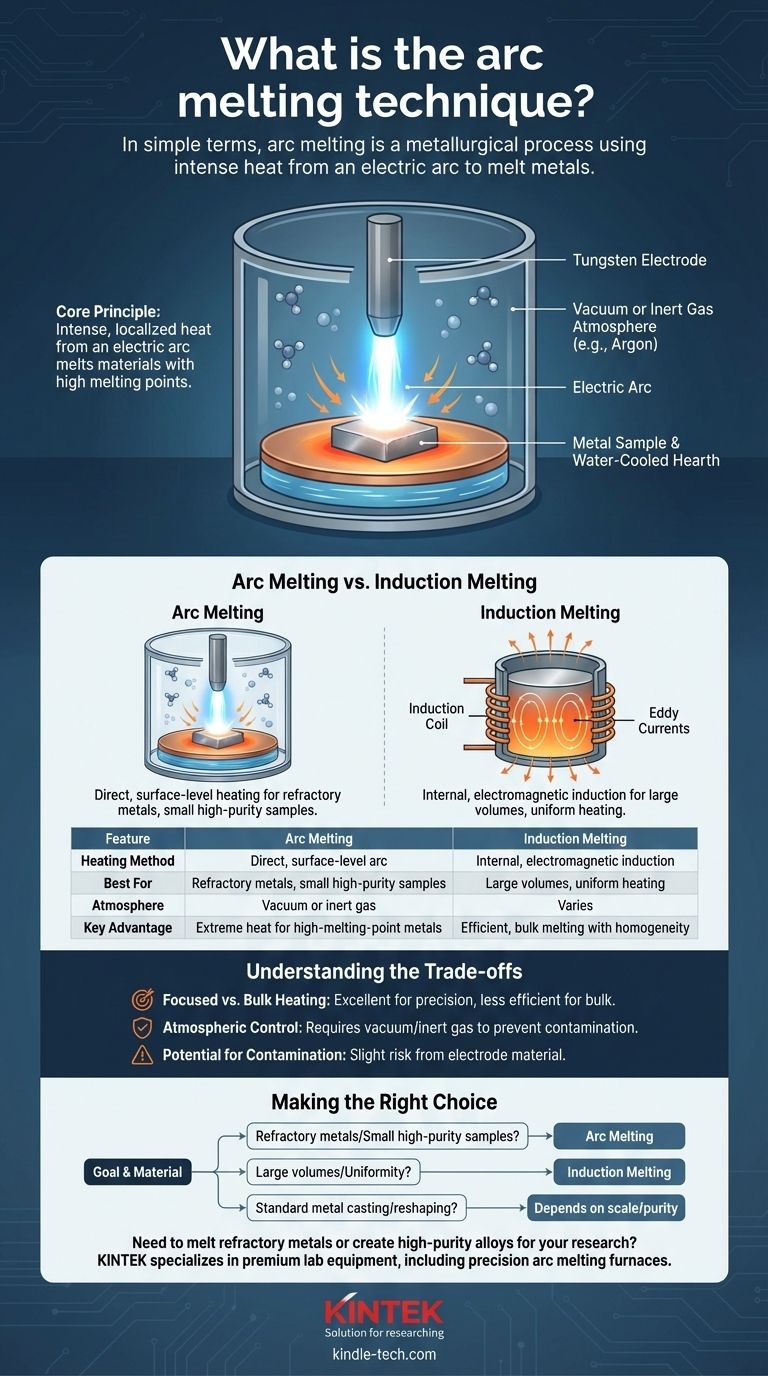

Arc Melting vs. Induction Melting: A Key Distinction

While both techniques melt metal, their methods and ideal uses are fundamentally different. Understanding this distinction is key to selecting the right process.

The Heating Mechanism

Arc melting uses direct, surface-level heating. The arc physically touches the material, transferring thermal energy from the outside in.

Induction melting, by contrast, uses electromagnetic induction. An alternating magnetic field creates electrical currents (eddy currents) inside the metal itself, causing it to heat up uniformly from within.

Material Suitability

The direct, intense heat of arc melting makes it superior for refractory metals like tungsten, titanium, and niobium, which have extremely high melting points.

Induction melting is often preferred for melting larger volumes or for materials where the uniform, contactless heating it provides is an advantage for achieving a homogenous liquid state quickly.

Understanding the Trade-offs

No technique is universally superior. The effectiveness of arc melting is tied to its specific characteristics, which come with inherent limitations.

Focused vs. Bulk Heating

The highly localized heat of an arc is excellent for precision work and creating small alloy buttons. However, it is less efficient for melting large, bulk quantities of metal compared to induction methods.

Atmospheric Control

Because the process operates at such high temperatures, the melting must often be done in a vacuum or an inert gas atmosphere (like argon). This prevents the hot, liquid metal from reacting with oxygen or nitrogen in the air, which would introduce impurities.

Potential for Contamination

While steps are taken to minimize it, there is always a slight risk of contamination from the electrode material itself. This is a critical consideration when absolute material purity is the primary goal.

Making the Right Choice for Your Goal

Selecting the appropriate melting technique depends entirely on the material you are working with and your desired outcome.

- If your primary focus is creating small, high-purity samples or melting refractory metals: Arc melting is almost always the superior choice due to its intense, controlled, and localized heat.

- If your primary focus is melting large volumes of metal with high efficiency and uniformity: Induction melting is generally the more practical and effective solution.

- If your primary focus is simply liquefying a standard metal for casting or reshaping: Either method can work, but the decision will depend on the required scale, speed, and purity of the final product.

Ultimately, choosing the right metallurgical process requires understanding how the method of heat transfer impacts your specific material and goals.

Summary Table:

| Feature | Arc Melting | Induction Melting |

|---|---|---|

| Heating Method | Direct, surface-level arc | Internal, electromagnetic induction |

| Best For | Refractory metals, small high-purity samples | Large volumes, uniform heating |

| Atmosphere | Vacuum or inert gas (e.g., Argon) | Varies |

| Key Advantage | Extreme heat for high-melting-point metals | Efficient, bulk melting with homogeneity |

Need to melt refractory metals or create high-purity alloys for your research?

KINTEK specializes in premium lab equipment, including arc melting furnaces designed for precision and purity. Our solutions are ideal for R&D labs working with titanium, tungsten, and other challenging materials.

Contact our experts today to discuss how the right melting technique can advance your material science projects. Let us help you achieve superior results with the perfect equipment for your specific needs.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the vacuum arc remelting process? Producing Ultra-Pure, High-Performance Metal Alloys

- How does vacuum arc remelting work? Achieve Ultra-Clean, High-Performance Metal Alloys

- What is a remelting process? A Guide to High-Purity Metal Refinement

- What is VAR in metallurgy? Achieve Superior Metal Purity and Performance

- What is var in metals? A Guide to Vacuum Arc Remelting for Superior Alloys