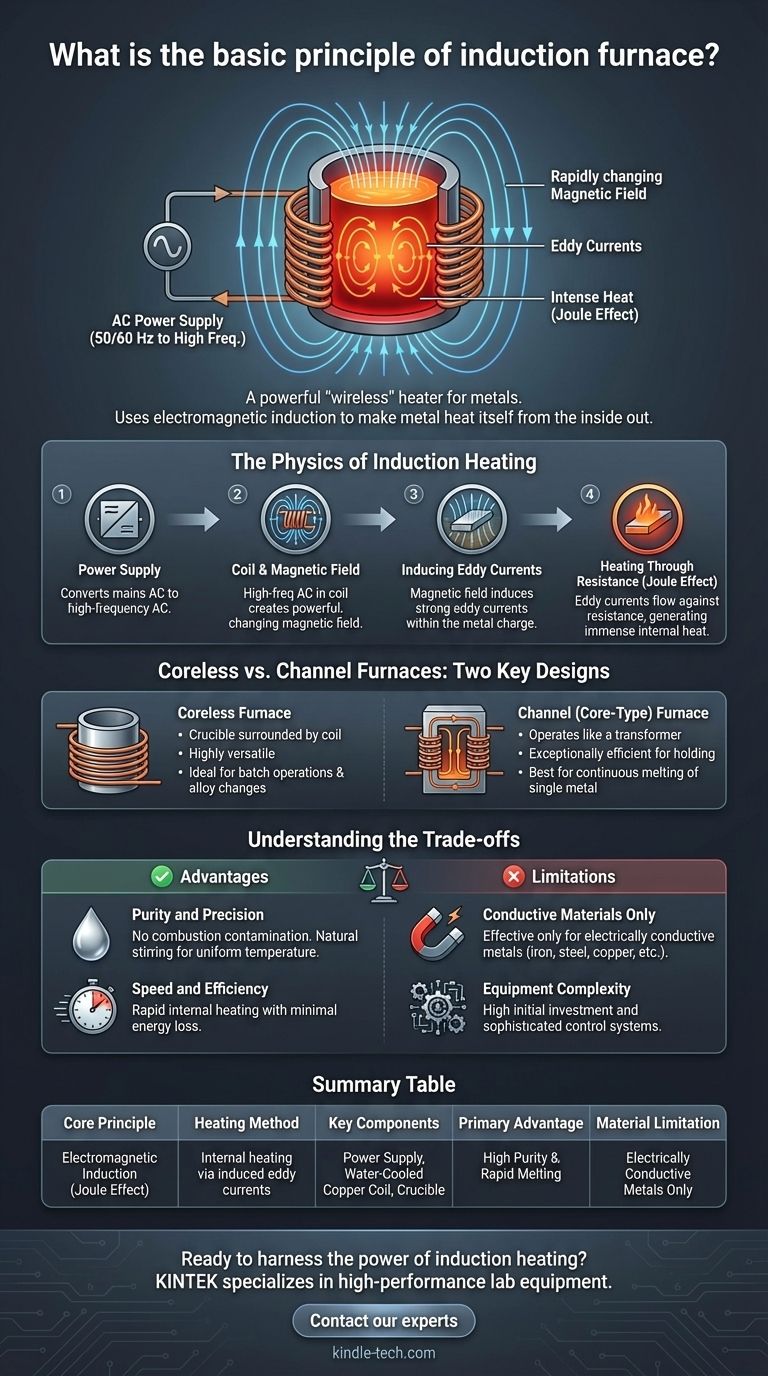

At its core, an induction furnace is a powerful "wireless" heater for metals. It uses a fundamental principle of electromagnetism to make a piece of metal heat itself from the inside out. An alternating electric current is passed through a copper coil, which generates a strong, rapidly changing magnetic field around the metal charge. This magnetic field, in turn, induces powerful electrical currents—known as eddy currents—directly within the metal, generating immense heat through resistance and causing it to melt.

The central principle is electromagnetic induction. Instead of applying external heat from a flame or electric arc, the furnace transforms the metal itself into the source of heat, leading to rapid, clean, and highly controlled melting.

The Physics of Induction Heating

To truly understand how an induction furnace operates, it's helpful to break the process down into a sequence of events, from the wall socket to the molten metal.

The Power Supply: Creating the Right Current

The process begins with the power supply, which converts standard mains frequency electricity (e.g., 50/60 Hz) into a high-power, medium-to-high frequency alternating current (AC).

This is often a multi-step process involving a rectifier to change AC to direct current (DC), followed by an inverter to change the DC back into AC at a much higher, controlled frequency (from 150 Hz to 8,000 Hz or more).

The Coil and the Magnetic Field

This specialized high-frequency AC is then channeled through a hollow, water-cooled copper coil.

According to Faraday's Law of Induction, any electric current generates a magnetic field. Because the current is alternating rapidly, it produces a powerful and constantly fluctuating magnetic field inside the coil.

Inducing Eddy Currents

The conductive metal to be melted (the "charge") is placed inside a crucible within the coil. The intense, changing magnetic field passes directly through this metal.

This field induces strong, circular electrical currents within the metal itself. These are called eddy currents.

Heating Through Resistance (The Joule Effect)

Like any material, the metal has inherent electrical resistance. As these powerful eddy currents flow through the metal against its own resistance, they generate immense heat.

This phenomenon is known as the Joule Effect. The heat is generated directly and internally within the charge, causing it to heat and melt with remarkable speed.

Coreless vs. Channel Furnaces: Two Key Designs

While the principle remains the same, induction furnaces are typically built in two primary configurations, each suited for different applications.

The Coreless Furnace

This is the most common design. It consists of a non-conductive crucible containing the metal, surrounded directly by the induction coil. The magnetic field directly penetrates the charge to induce eddy currents.

Coreless furnaces are highly versatile, excellent for melting a wide range of metals from a cold start, and are ideal for batch operations where alloy composition changes frequently.

The Channel (or Core-Type) Furnace

This design operates more like a transformer. A primary coil is wound around an iron core, and a closed loop of molten metal acts as the secondary coil.

Current induced in this molten metal loop generates heat, which circulates into a larger bath of metal. These furnaces are exceptionally efficient but are best suited for holding large volumes of molten metal at temperature or for melting a single type of metal continuously, as they require a "heel" of molten metal to start.

Understanding the Trade-offs

No technology is without its limitations. An objective evaluation requires understanding both its strengths and weaknesses.

Advantage: Purity and Precision

Because the heat is generated internally without any combustion, there is no contamination from fuel or electrodes. The electromagnetic forces also create a natural stirring action, ensuring a highly uniform temperature and homogenous alloy composition.

Advantage: Speed and Efficiency

Induction heating is incredibly fast. Since heat is generated directly in the material, energy transfer is highly efficient, with minimal heat lost to the surrounding environment compared to other furnace types.

Limitation: Conductive Materials Only

The core principle relies on inducing current within the charge. Therefore, this technology is only effective for melting electrically conductive materials like iron, steel, copper, aluminum, and precious metals.

Limitation: Equipment Complexity

The high-power, variable-frequency power supplies are sophisticated and represent a significant capital investment. The control systems and water-cooled coils add to the overall complexity of the installation.

Making the Right Choice for Your Goal

Understanding the principle allows you to select the right approach for a specific metallurgical objective.

- If your primary focus is high-purity alloys or frequent batch changes: A coreless induction furnace offers the necessary flexibility and clean melting environment.

- If your primary focus is holding large volumes of a single molten metal: A channel induction furnace provides unparalleled energy efficiency for maintaining temperature.

- If your primary focus is rapid melting and process control: Induction heating in general is superior to traditional methods due to its speed and the precision offered by modern control systems.

Ultimately, the principle of induction transforms a piece of metal into its own highly efficient, self-contained heat source.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | Electromagnetic Induction (Joule Effect) |

| Heating Method | Internal heating via induced eddy currents |

| Key Components | Power Supply, Water-Cooled Copper Coil, Crucible |

| Primary Advantage | High Purity & Rapid Melting |

| Material Limitation | Electrically Conductive Metals Only |

Ready to harness the power of induction heating in your lab or foundry?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for precise, clean, and efficient metal melting. Whether you are working with research alloys or production metals, our solutions deliver the purity and control you need.

Contact our experts today via our Contact Form to discuss how an induction furnace can transform your melting process and meet your specific laboratory goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What does induction heating depend on? Master the 4 Key Factors for Precision Heating

- What are the limitations of induction heating? Understanding Its Material and Cost Constraints

- What is the range of induction heating? Understanding Coupling Distance and Skin Effect

- What is the function of a vacuum induction melting furnace? Essential Guide for High-Purity FeCrAl Alloy Production

- What is the process of induction brazing? Achieve Fast, Precise, and Repeatable Metal Joining

- How is temperature controlled in induction heating? Master Precise Thermal Management

- What is the frequency of induction melting furnace? Optimize Your Melting Process with the Right Frequency

- What are the different types of induction furnaces? Coreless vs. Channel for Your Melting Needs